ebm-papst Partners with Emmi to Elevate Freshness in Logistics Cooling

10/31/2025In the realm of milk preservation, ebm-papst has joined forces with Emmi, a leading Swiss milk processor, to advance logistics cooling and maintain product freshness.

Matthias Künzli, an automation expert at Emmi, focused on a long-term project at the Suhr production base: modernizing the warehouse cooling system at the Suhr logistics center. His key move was replacing AC fans in the cooling system with modern EC fans to boost energy efficiency.

Sustainability is a core part of Emmi’s strategy and a foundation for its operations. Guided by its sustainability model and net-zero emission plan, the company has set science-based greenhouse gas reduction targets, as noted by Künzli.

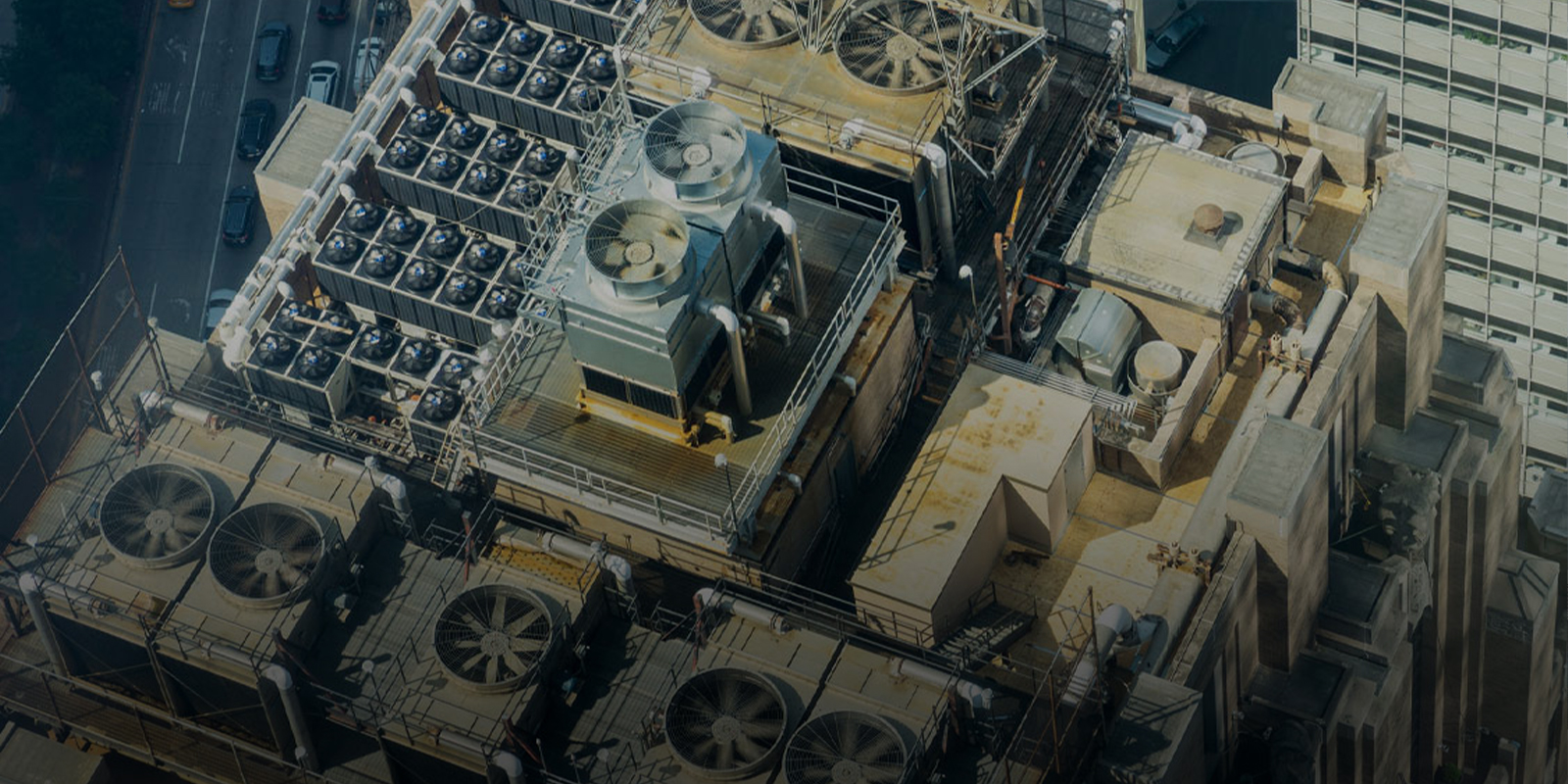

The Need for Cooling System Upgrade

Reliable fan cooling is essential to keep products in the logistics center fresh. Dairy products, fruits, vegetables, and meat all require low-temperature storage. However, the warehouse’s cooling system had been in use for over 20 years. Its refrigeration fans lacked controllability and could no longer meet current demands.

After examining the existing fans, Künzli was surprised to find the logistics center consumed excessive electricity. Many fans had more power than needed, yet their speed couldn’t be reduced. To optimize energy use and align with sustainability goals, he decided to fully modernize the center’s cooling system.

Making the Impossible Possible

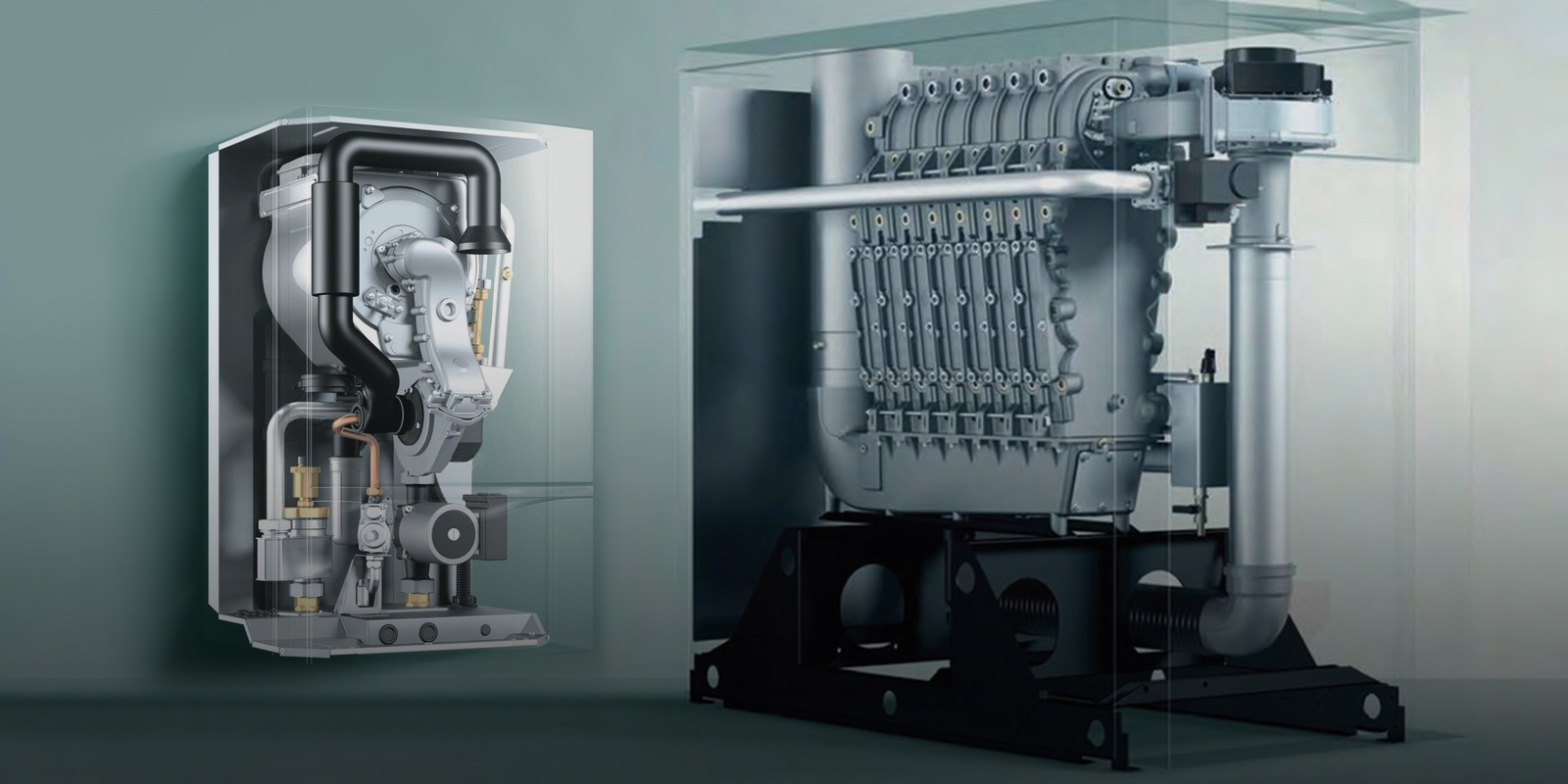

Künzli refused a quick fix, such as replacing the evaporators outright. Instead, he wanted to install advanced fans on the existing equipment to stay true to Emmi’s sustainability strategy. Evaporators are durable with few wearing parts, so discarding them would contradict the company’s sustainability values.

He carefully evaluated different fan types, measured power consumption, and compared power levels and air volume. He also sought partners to upgrade the evaporators. Unfortunately, most refrigeration equipment suppliers he consulted suggested scrapping the evaporators entirely.

A turning point came in 2020. Künzli attended a seminar hosted by ebm-papst and was impressed by the performance of modern EC fans. From the start, ebm-papst’s team supported his project, emphasizing that “nothing is impossible.”

Good Planning Yields Great Rewards

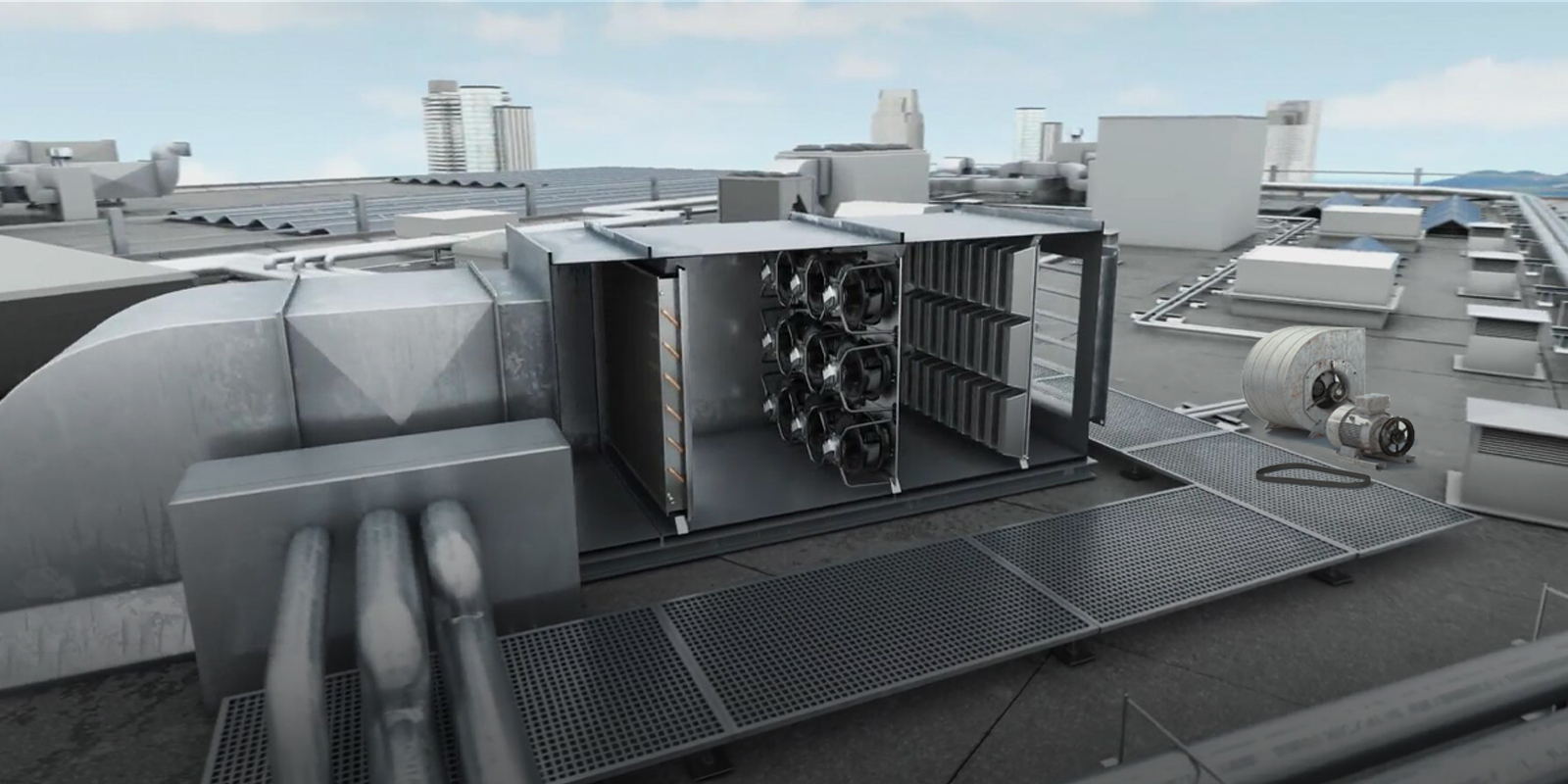

The upgrade was carried out while the system was operational. Künzli and his assistant Arber Gashi disassembled each type of evaporator and installed ebm-papst fans. To ensure the cooling system could resume use immediately, they pre-identified and manufactured the brackets needed for the existing evaporators, allowing direct installation of the new fans.

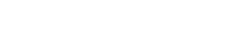

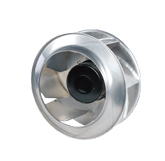

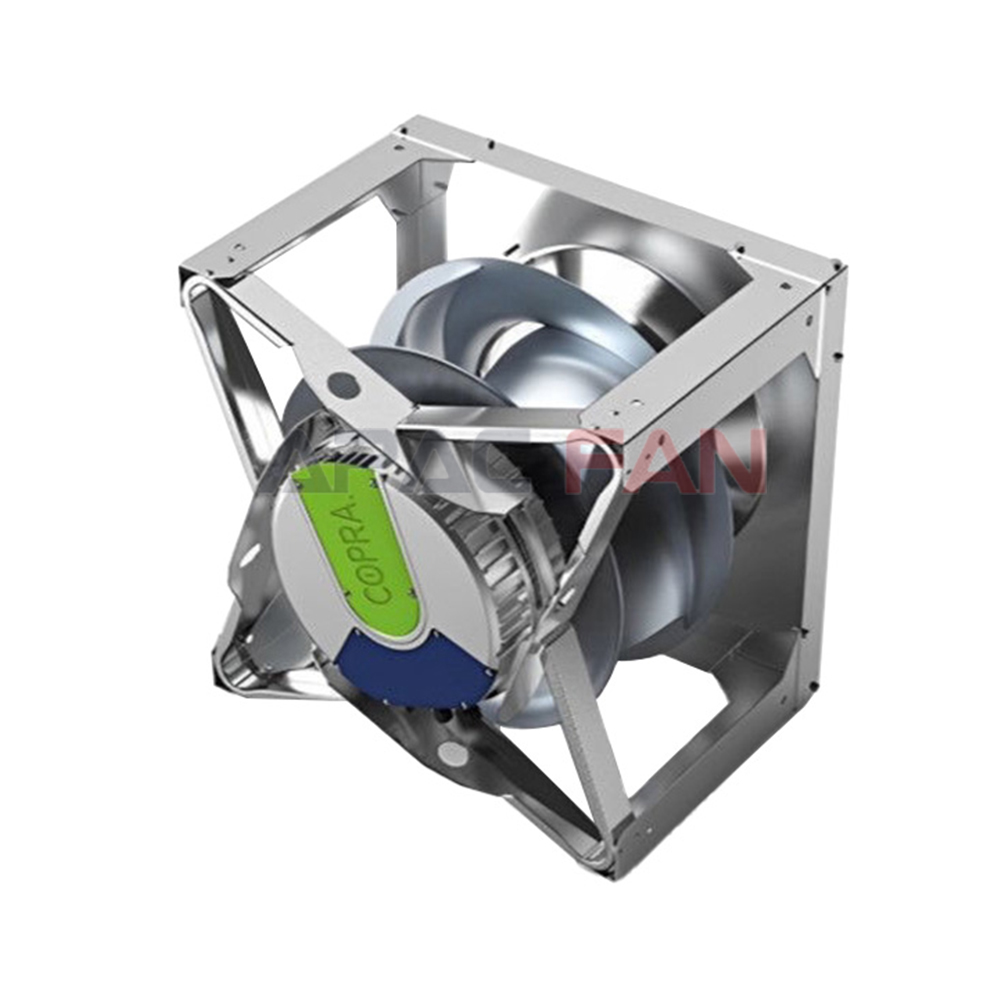

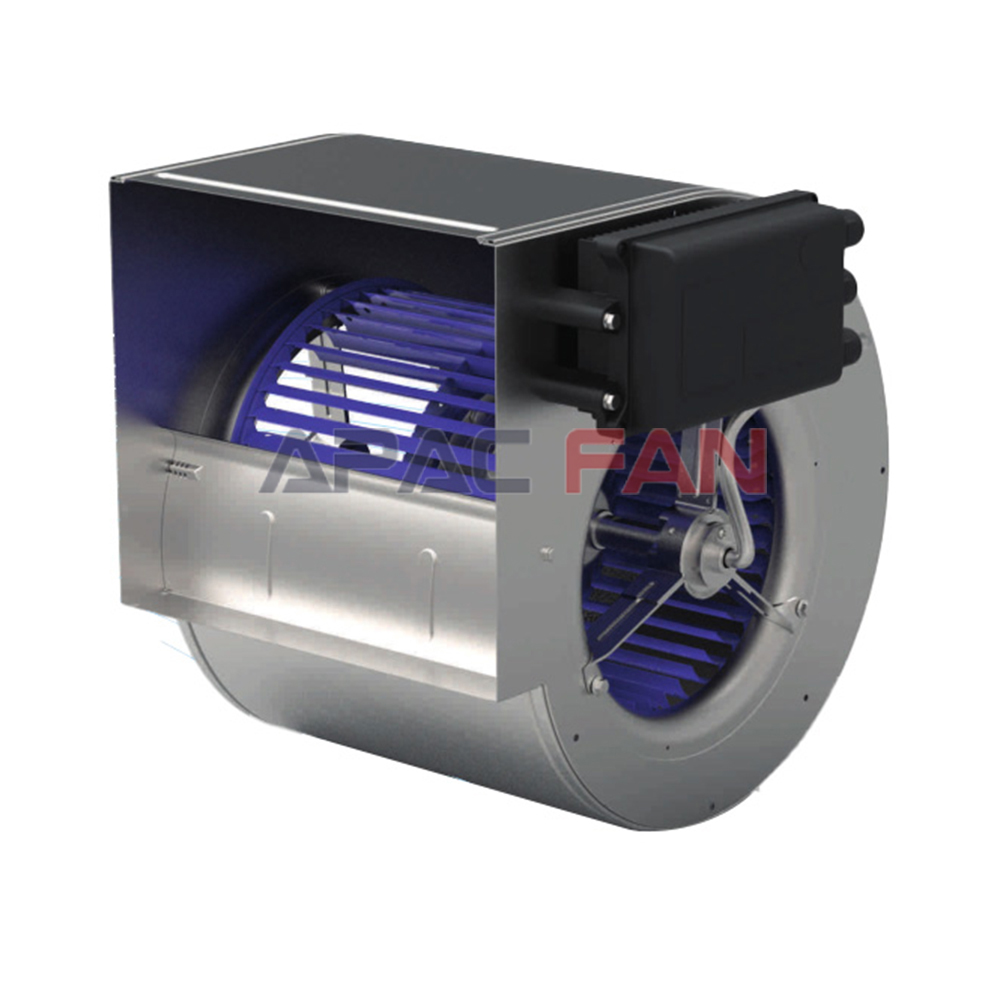

Three AxiEco axial fans with short-nozzle protective grilles were installed on each of 9 evaporators. These fans have strong pressure resistance, come in sizes ranging from 300mm to 910mm, and feature aerodynamically optimized impellers, sturdy grilles, and easy-to-install housings. They offer low energy consumption, shallow installation depth, low noise, and high efficiency. Additionally, three HyBlade axial fans were fitted to each of 27 other evaporators.

Shortly after installation, measurements showed that the power consumption of each evaporator dropped from 8 amps to 1 amp.

Over 80% Energy Savings

Beyond the smooth completion of the upgrade, Künzli was delighted with the remarkable results: “ebm-papst promised us approximately 50% energy savings. In fact, most fans achieved over 80% energy reduction. Fifty percent comes from the fans’ high efficiency, and the other 30% is due to our ability to lower fan speed based on demand.”

What motivated Künzli wasn’t just the numbers. He was pleasantly surprised by the new fans’ near-silent operation—so quiet that he had to check the visualization system to confirm they were running. The logistics center has a speaker system that plays background music and announcements during working hours. Previously, employees could never hear the content clearly; now, they can.

The project covered two of the logistics center’s four floors and the entire basement, with 206 new fans installed. According to Künzli’s current calculations, this will save approximately 550,000 kWh of electricity annually.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文