Behind DRe24's Lightning Speed: The Game-Changing Role of ebm-papst 4114N/2H8P

10/30/2025As the roar of the racing car’s engine cuts through the air above the track and the vehicle flashes past the corners like lightning, an ultimate contest of speed and endurance kicks off. For DIAN Racing from Tongji University, the newly launched DRe24 racing car in 2024 is not only the ultimate showcase of the team’s technical strength, but also a vivid example of how ebm-papst’s fan technology deeply empowers the racing field. From the precise design of the heat dissipation system to the stable support for performance, ebm-papst uses professional fan technology to write a wonderful chapter of "technology empowering speed" on the racing track.

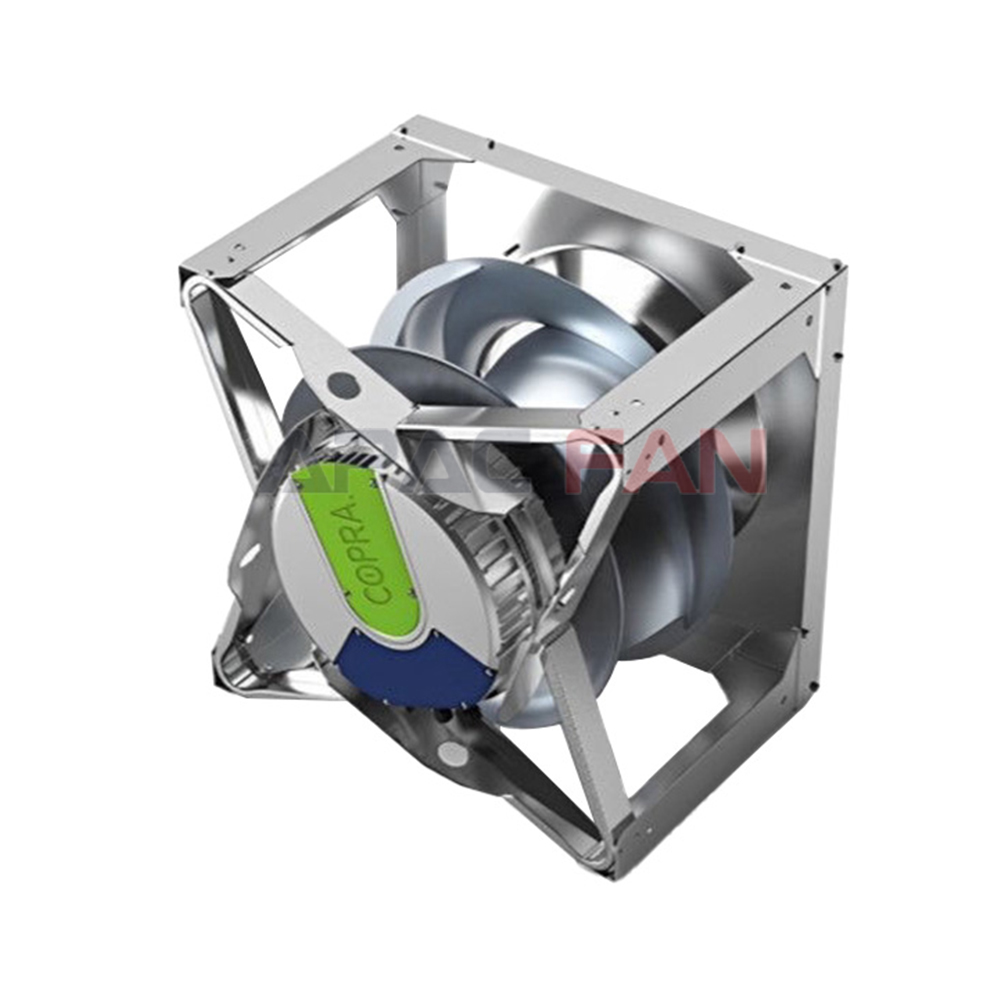

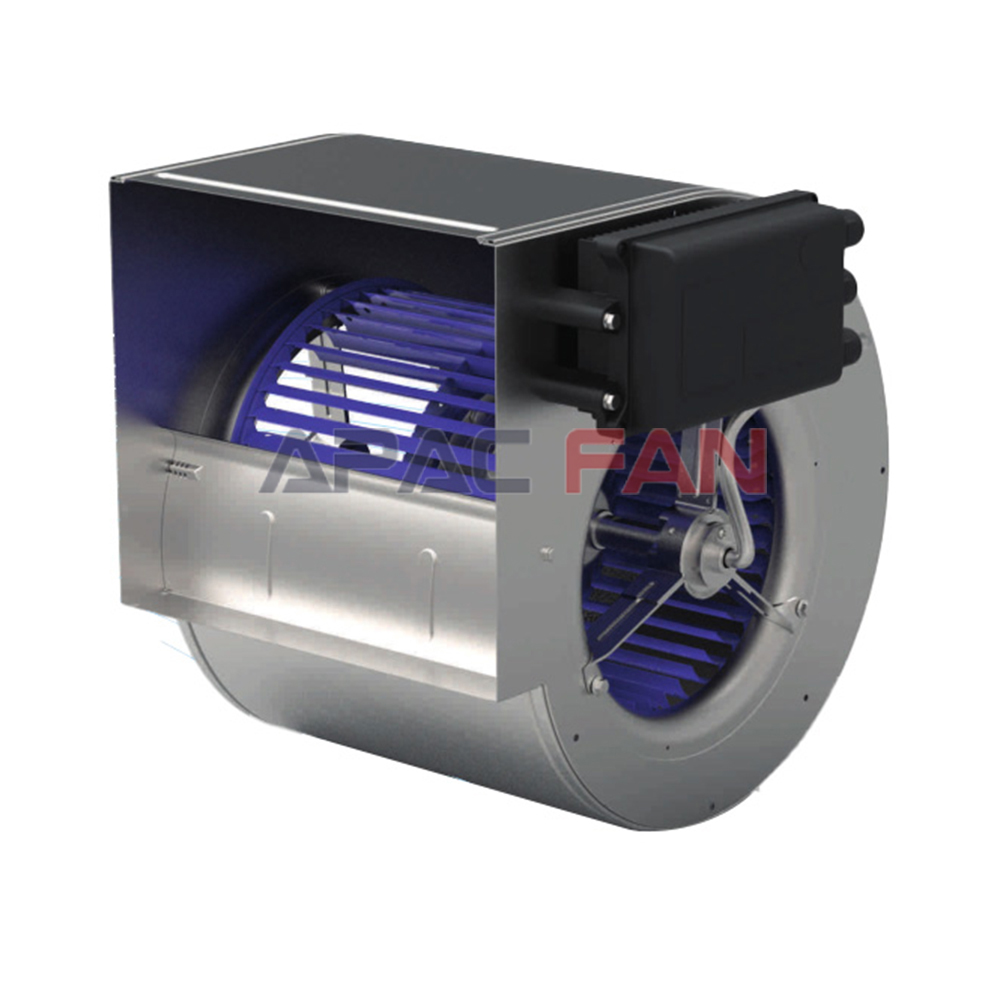

In the competitive world of electric racing cars, "heat dissipation" is a key factor determining whether a racing car can continuously release its performance. Different from traditional fuel-powered racing cars, the core components of electric racing cars such as motors, controllers and inverters generate a lot of heat during high-speed operation. If heat is not dissipated in time, it will not only lead to the attenuation of component performance, but also may cause safety hazards, directly affecting the racing car’s performance in endurance races. It is precisely by insight into this core demand that the DRe24 racing car took the heat dissipation system as a top priority at the beginning of its design. The addition of ebm-papst’s compact axial fans just provides the optimal solution for this demand.

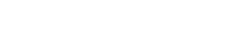

At the rear of this year’s DRe24 racing car, three sets of ebm-papst fans are neatly arranged, forming a perfect cooperation with the racing car’s heat dissipation water circuit system. The front-wheel motor, rear-wheel motor and inverter are each equipped with an independent series water circuit. When the water flow circulates to the rear with the heat of the components, the ebm-papst fans start immediately, accelerating heat evaporation with strong wind power, and building a dual protection system of "water circuit heat conduction + fan heat dissipation". Among them, the 4114N/2H8P compact fan, which undertakes the core heat dissipation task, has become the "power heart" of the racing car’s heat dissipation system with its core advantages of "small size, high power and strong wind force". It can continuously deliver high-flow cold air, accurately covering the key heat dissipation areas. Finally, it achieves the excellent effect of stably controlling the steady-state temperature of the inverter below 50°C and strictly maintaining the motor temperature below 125°C. This data is not only far lower than the safe temperature threshold of the core components of electric racing cars in the industry, but also ensures that the DRe24 racing car can still maintain stable performance even under the dual tests of high-intensity operation and complex track environment during the endurance race lasting for several hours, avoiding power fluctuations or failure risks caused by excessive temperature.

What is more noteworthy is that the 4114N/2H8P fan on the 2024 DRe24 racing car is also equipped with the innovative PWM speed regulation function developed by ebm-papst. This technical upgrade has made "intelligent heat dissipation" a reality. In the past, traditional fans mostly adopted the fixed-power operation mode. Regardless of the temperature of the core components, the fans always maintained the same speed, which not only caused unnecessary power consumption of the low-voltage battery, but also might affect the service life of the components due to excessive or insufficient heat dissipation. The PWM speed regulation function has completely changed this situation: it can receive the temperature sensing data of the motor and controller in real time, and dynamically adjust the fan power according to the actual temperature change of the components. When the temperature is lower than the safe threshold, the fan automatically reduces the speed to reduce power consumption; when the temperature is close to the warning value, the fan immediately increases the power to strengthen the heat dissipation. This "on-demand adjustment" intelligent mode not only saves the precious low-voltage battery power for the DRe24 racing car and extends the racing car’s battery life, but also realizes the precise control of the heat dissipation water temperature, keeping the core components in the "optimal working temperature range" at all times, providing double support for the racing car’s explosive power and durability on the track.

From technical cooperation to the implementation of results, the cooperation between DIAN Racing (Tongji University) and ebm-papst has long transcended the simple "supplier-customer" relationship and become a model of school-enterprise cooperation promoting technological innovation. During the R&D process of the DRe24 racing car, the ebm-papst team always focused on the actual needs of the racing team and deeply participated in the scheme design of the heat dissipation system. From the customized matching of fan voltage and power, to the precise adaptation of fan size to the rear space of the racing car, and then to the coordinated commissioning of the PWM speed regulation function and the racing car control system, every detail has gone through repeated polishing and testing. Just as the students of Tongji Electric Racing Team said in the communication: "ebm-papst never simply provides products, but truly deeply understands our competition needs and technical pain points. According to our specific requirements for heat dissipation efficiency, energy consumption control and spatial layout, it customizes the most suitable solution. This professional service 'oriented by needs' has helped us avoid many detours in the R&D of racing cars, and also made us more confident in the track performance of DRe24."

Today, when the DRe24 racing car is speeding on the track, the three ebm-papst fans at the rear of the car may not be eye-catching, but they are silently writing the story of "technology empowering speed". It not only witnesses the successful application of ebm-papst’s fan technology in the racing field, but also proves the important value of professional technology for competitive sports. Behind the competition of speed and passion, there are technical partners like ebm-papst, who provide solid guarantees for every sprint that breaks the limit with accurate, reliable and innovative solutions, making the racing car’s "speed dream" have a more solid technical support.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文