South German Parts Maker Cuts Energy Use via Ventilation Retrofit

09/24/2025A South German parts manufacturer has enhanced its ventilation systems through innovative technology. AIRnorm GmbH experts showed that retrofitting with the newest ebm-papst fans and a FanGrid can lower energy use by 30% and greatly improve operational reliability.

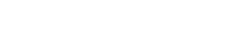

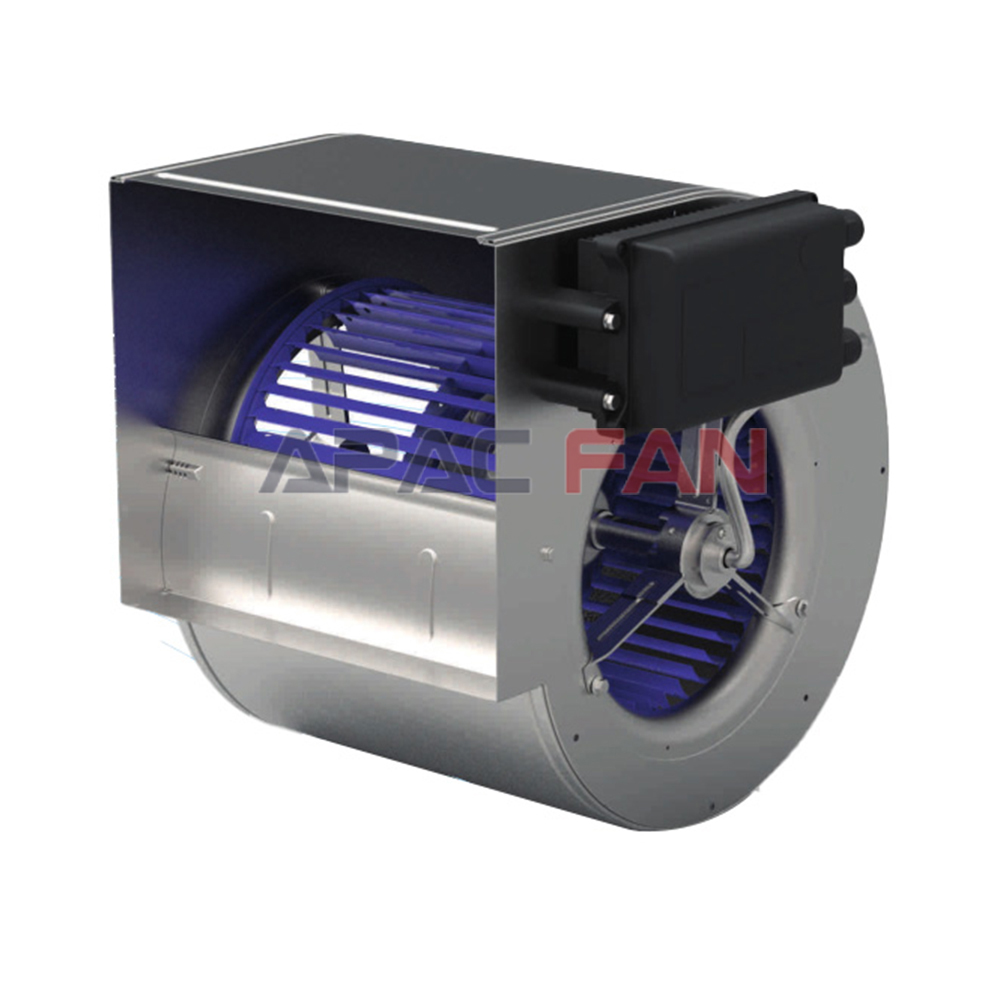

The former systems, run by multi-speed motors and V-belts, had flaws in wear, maintenance and control. AIRnorm studied operating data, identified current parameters, and used ebm-papst’s FanScout program to pick suitable fans and prove savings potential. The solution—replacing fans and designing a new pressure wall—would reduce differential pressures, enhance flow and boost energy efficiency, with the investment to be recouped in under four years.

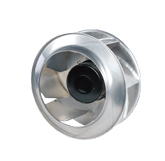

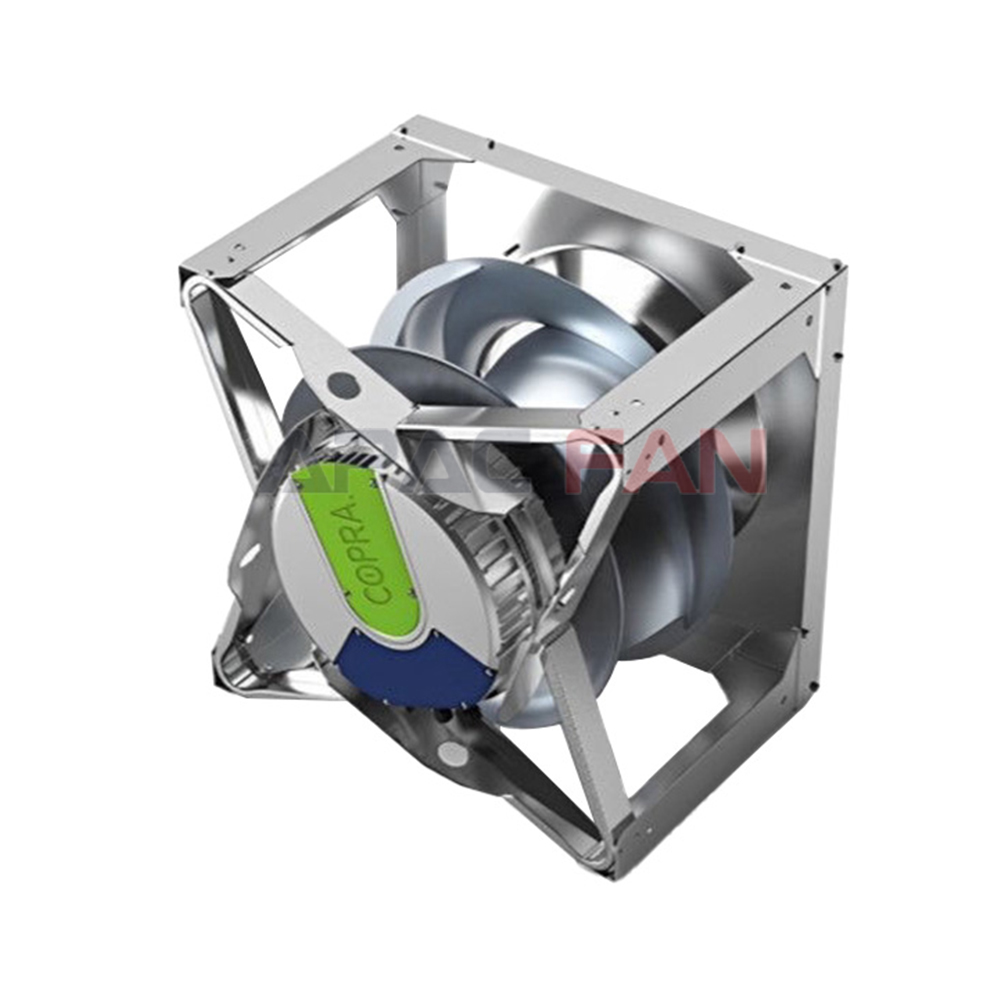

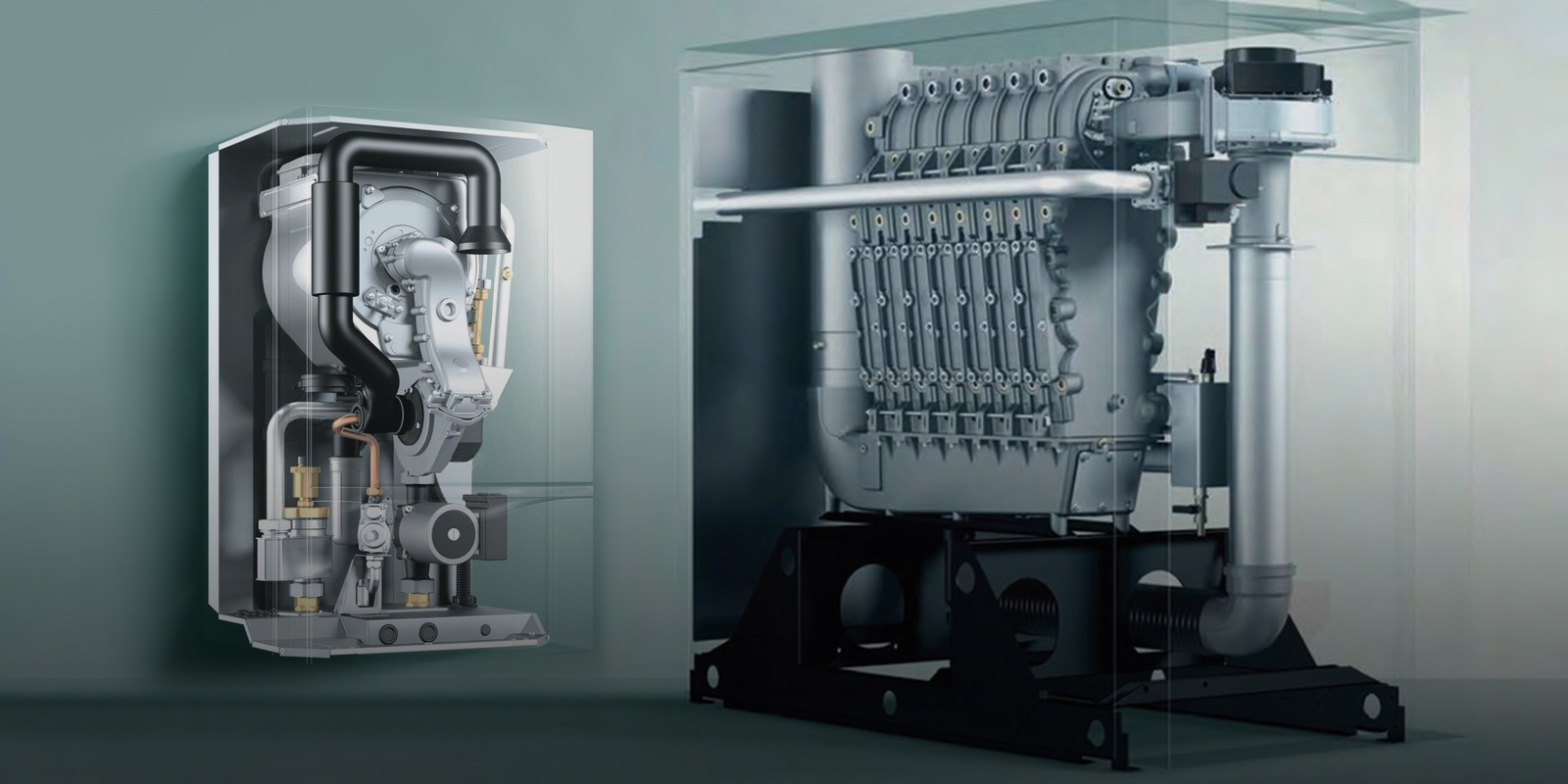

For fast results, AIRnorm worked closely with Breuell & Hilgenfeldt, ebm-papst’s retrofit sales partner. The retrofit team chose ebm-papst’s RadiPac C EC centrifugal fan, which has a compact 6 kW drive (highly efficient even at partial load). It also has plug-and-play functionality and a support bracket for easy wall mounting, plus automatic resonance detection to avoid harmful vibrations and early bearing damage.

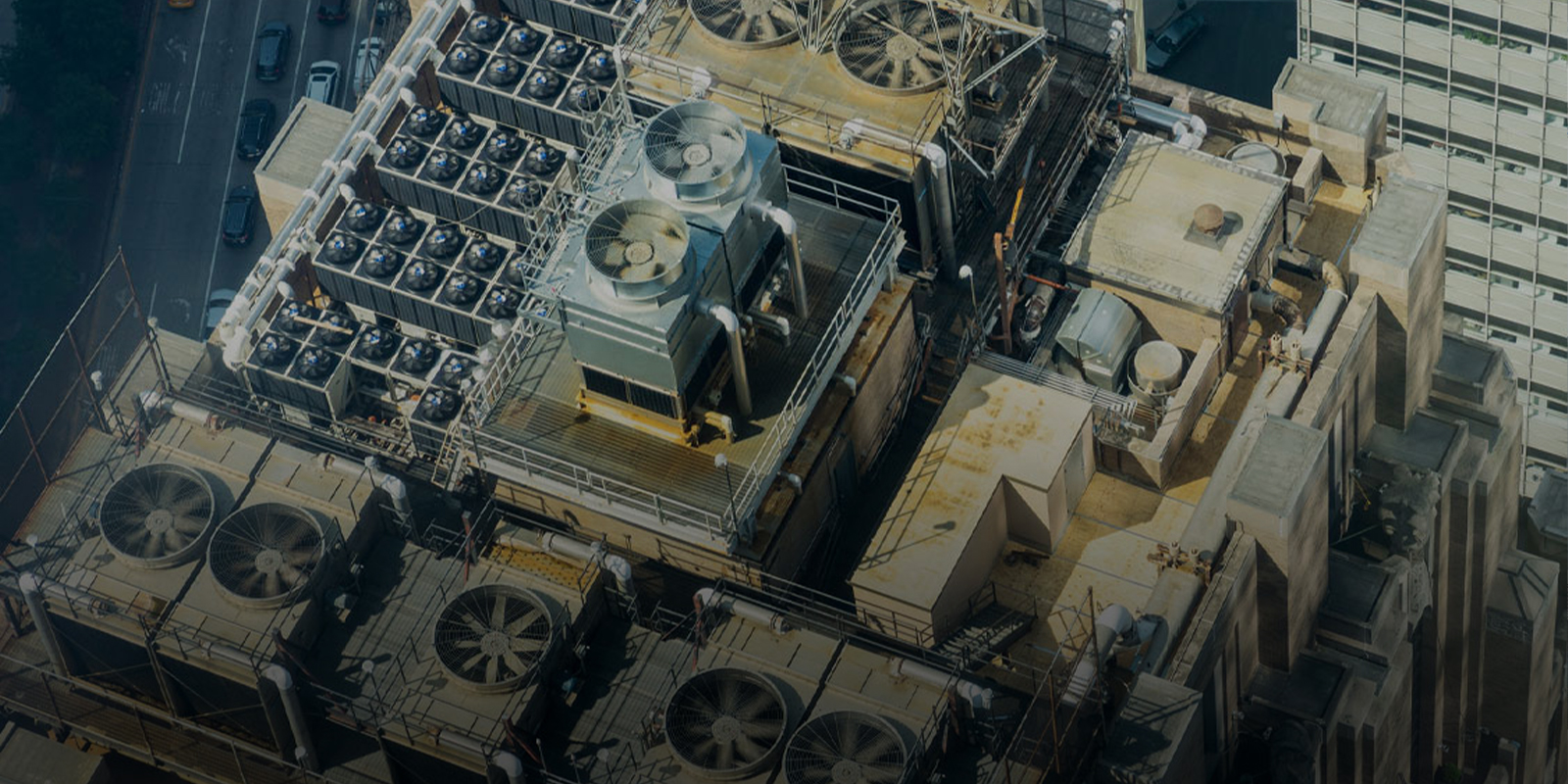

There are four production buildings with similar ventilation setups. Hall 2’s system is vital because it extracts exhaust air from machinery—any breakdown would halt production. Thus, the retrofit started here, taking just three and a half days during the summer shutdown. The customer provided hoisting equipment to safely remove the old 320-kilogram motor.

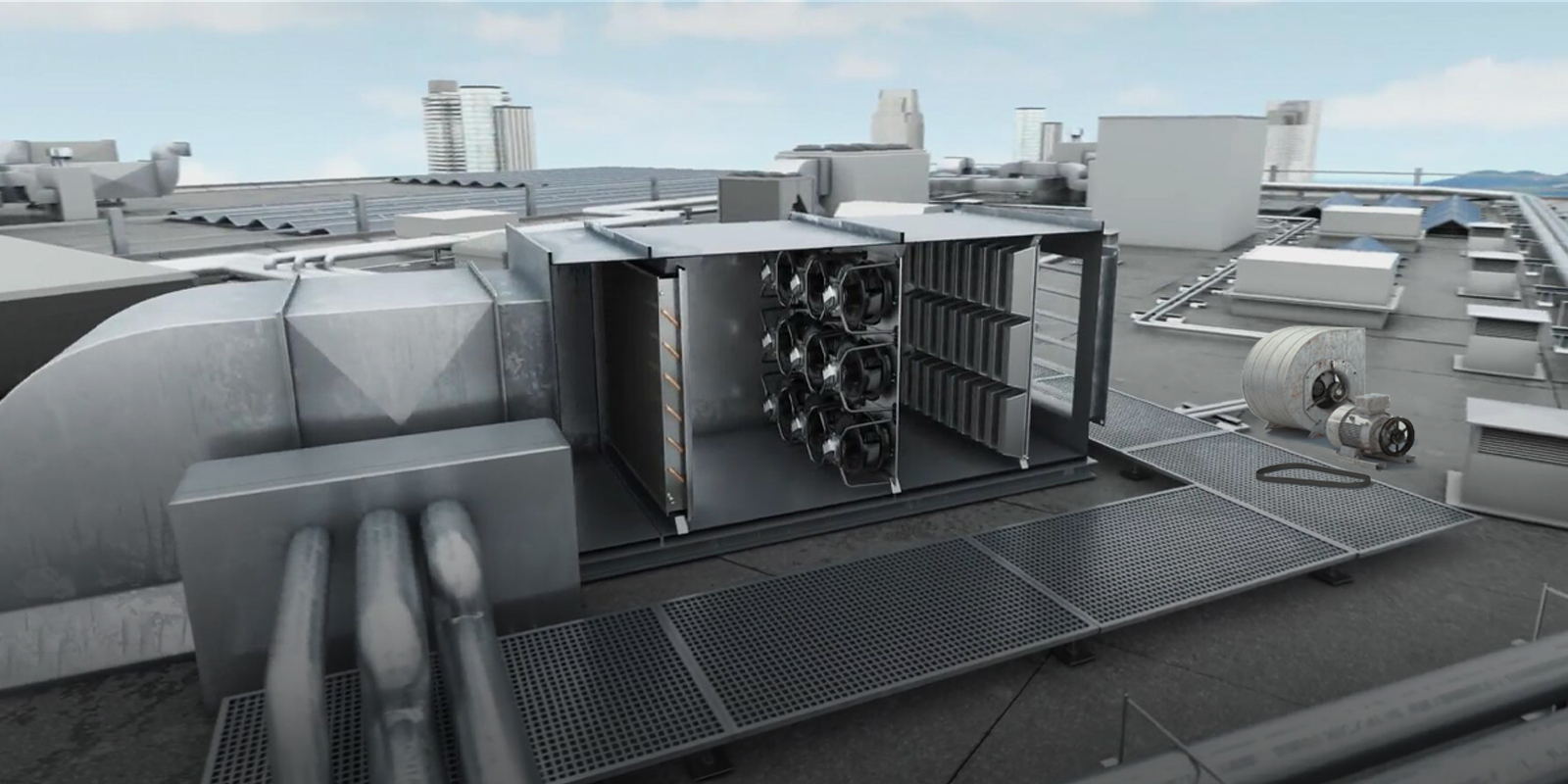

Beyond energy savings, a key reason for the project was maximizing operational reliability. The FanGrid’s redundancy (letting multiple fans run in parallel) keeps output steady if one fan fails, preventing production stops. Two control cabinets with MDC now control the fans, replacing the old variable frequency drives. After system commissioning, all values were verified, and annual energy savings will reach around 54,000 kWh going forward.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文