Slash Energy Use in India via Fan Retrofits & ECC Control

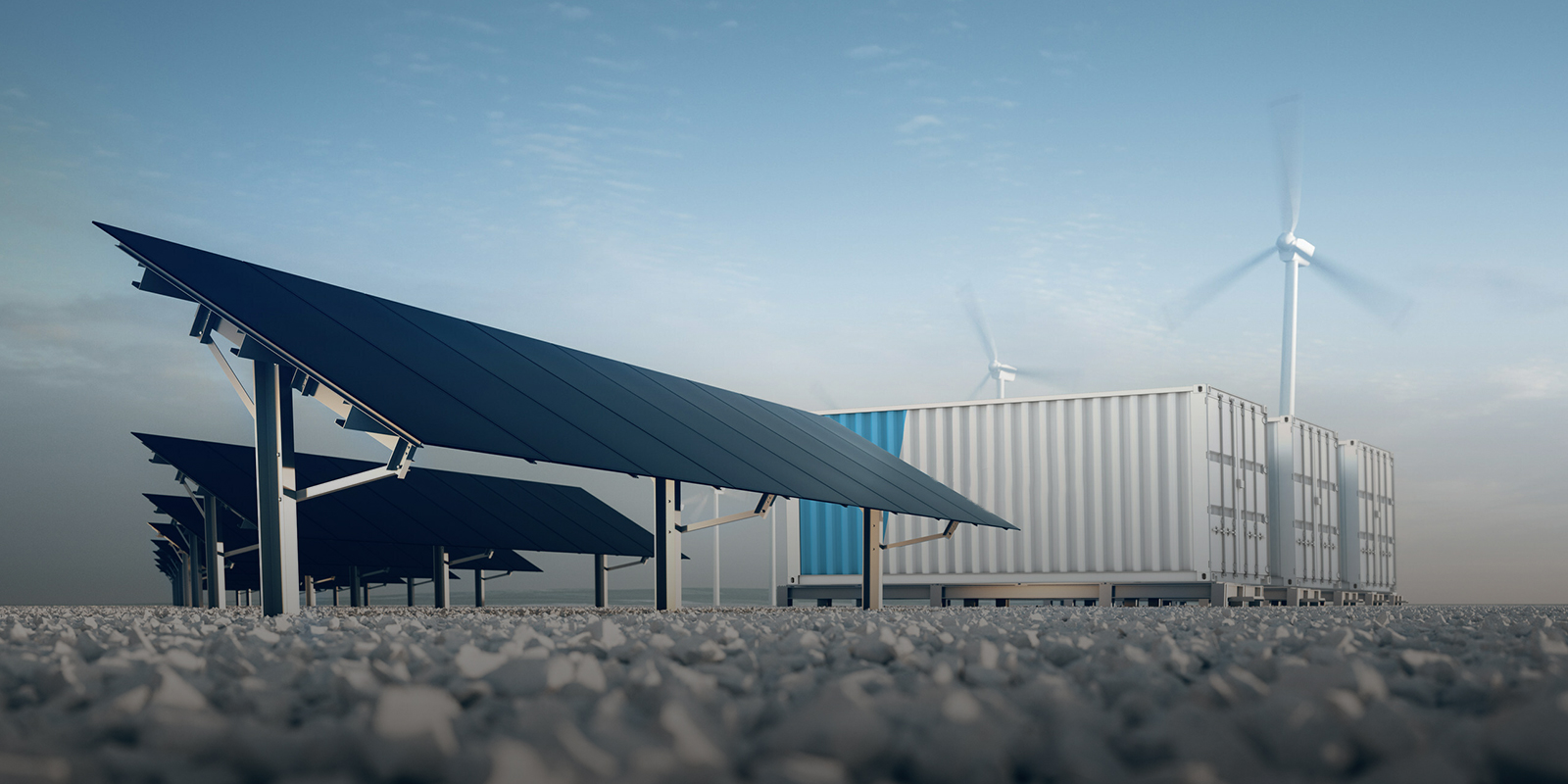

09/23/2025As a world-renowned pioneer in corporate and technological transformation, Capgemini consistently adopts sustainable solutions in India to meet its climate objectives. Two key elements are instrumental to this effort: large-scale retrofitting of ventilation systems, which uses high-efficiency EC fans from ebm-papst, and centralized control enabled by the Energy Command Center (ECC).

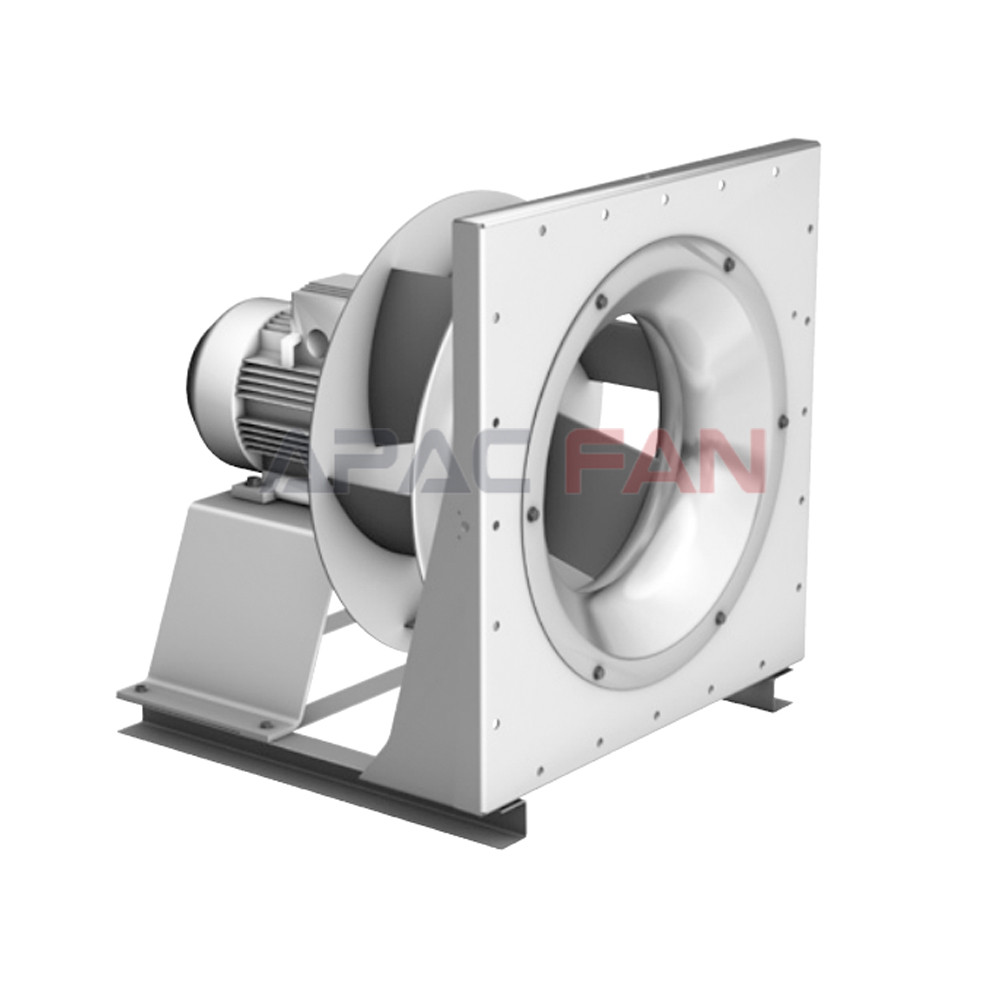

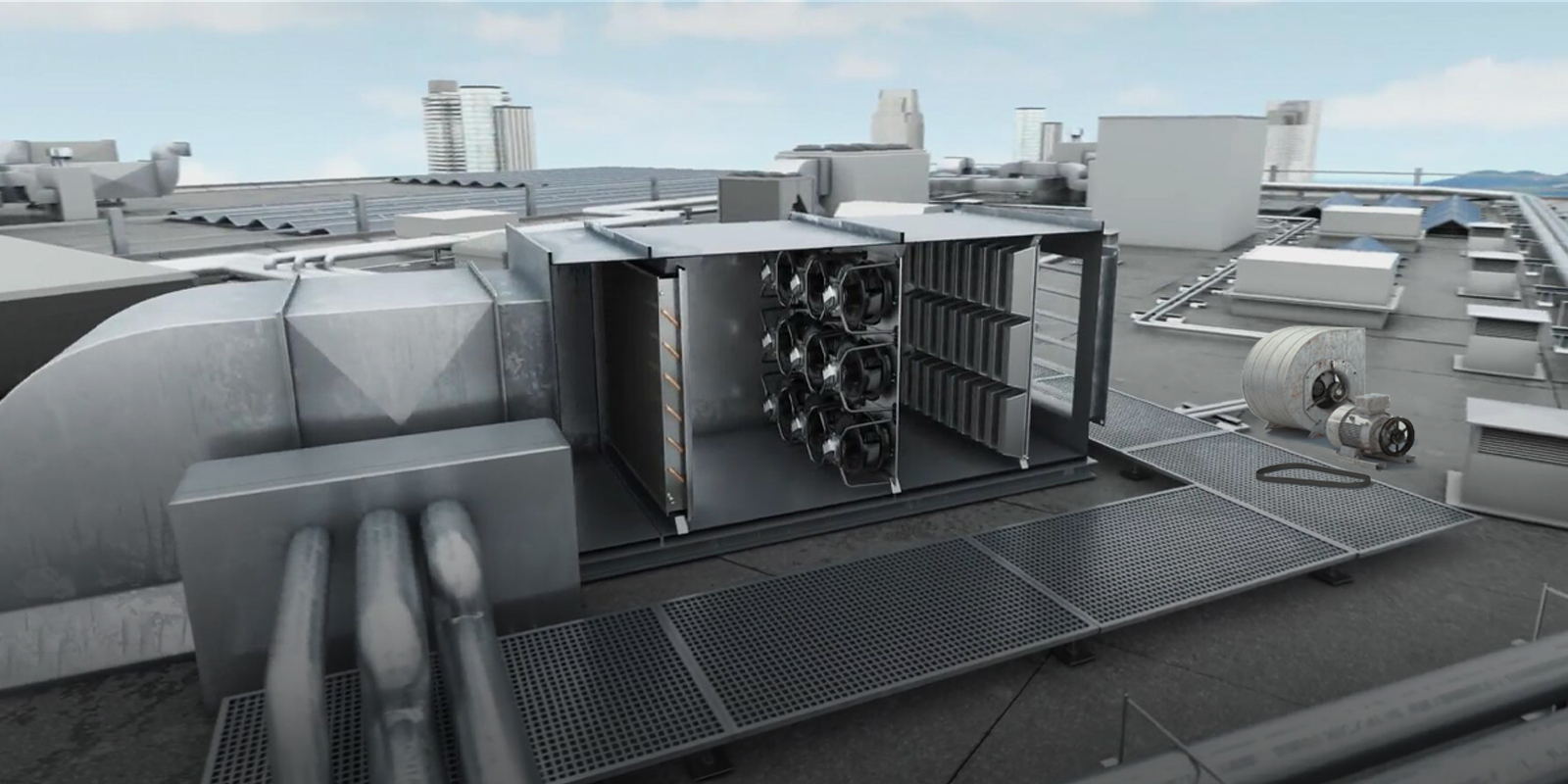

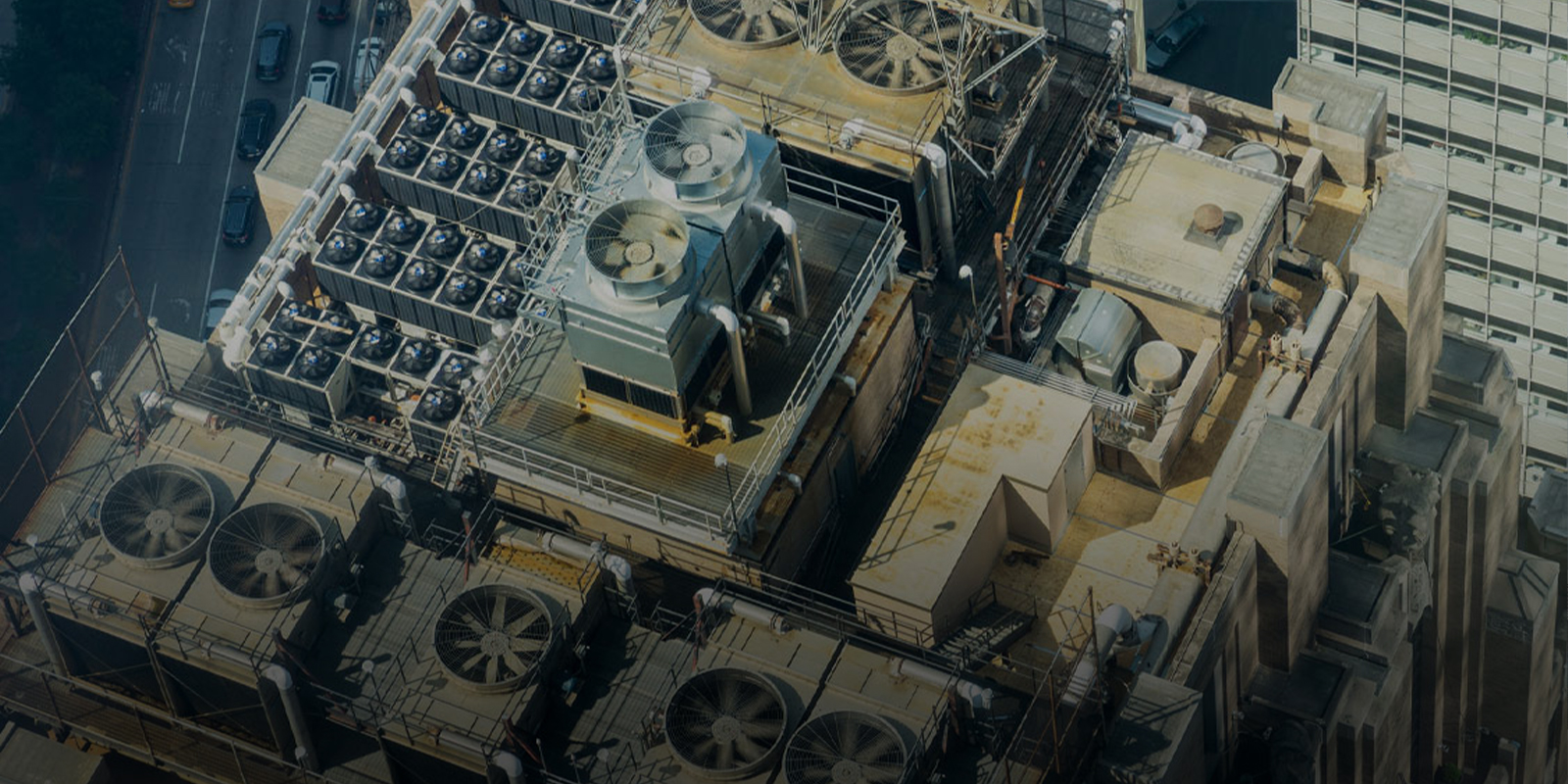

Since 2016, Capgemini has been working toward reducing energy consumption in its real estate and shrinking its environmental impact. Through close collaboration with ebm-papst, the company has already replaced over 1,000 fans across eight sites in India. Previously, its old ventilation systems—covering air conditioners, air handling units, cooling towers, and precision air-conditioning units for data centers—were outfitted with outdated fans that consumed high amounts of energy. The adoption of advanced EC technology has led to substantial energy savings.

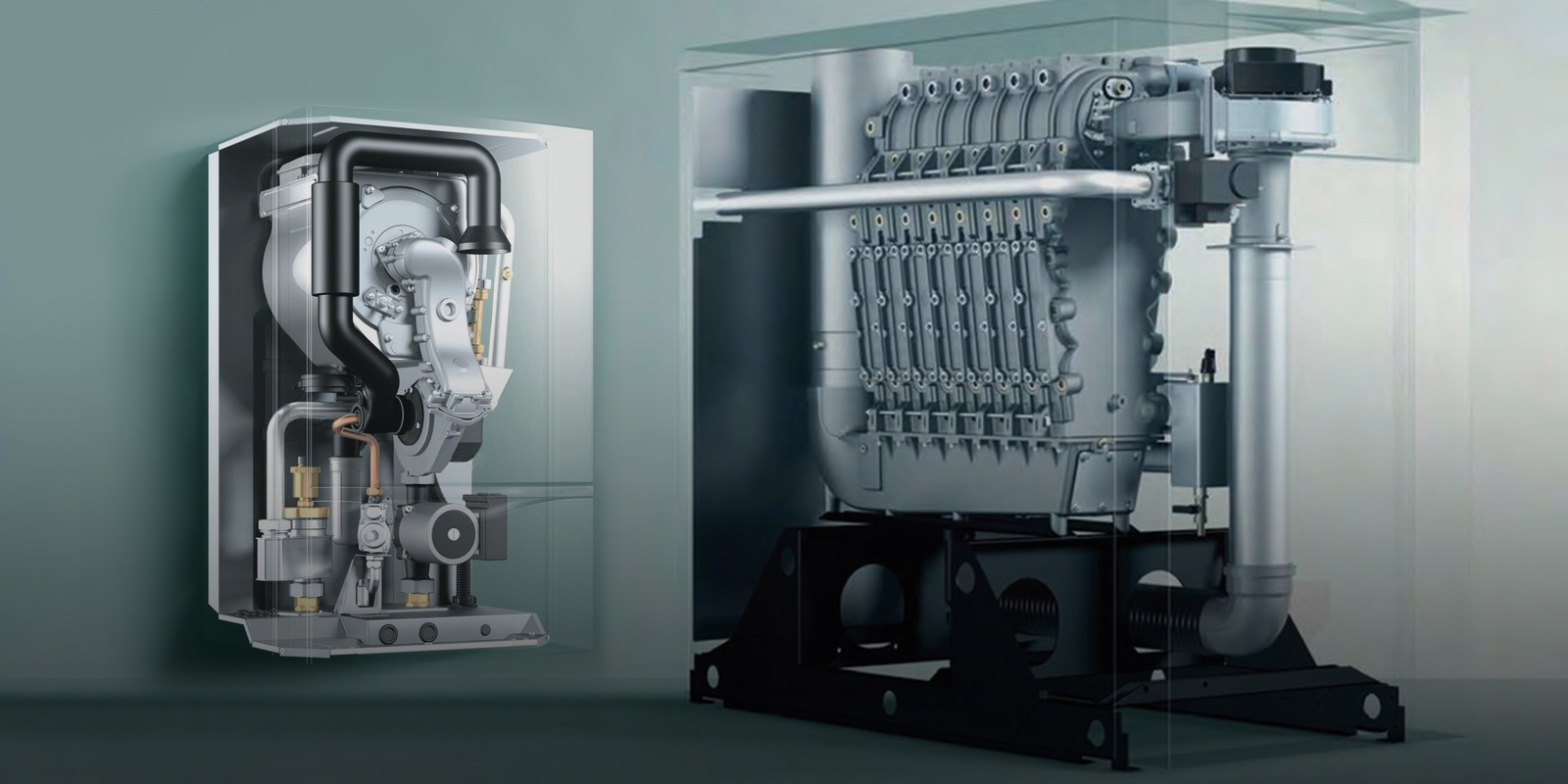

AxiBlade and RadiCal 2 boost energy efficiency

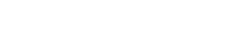

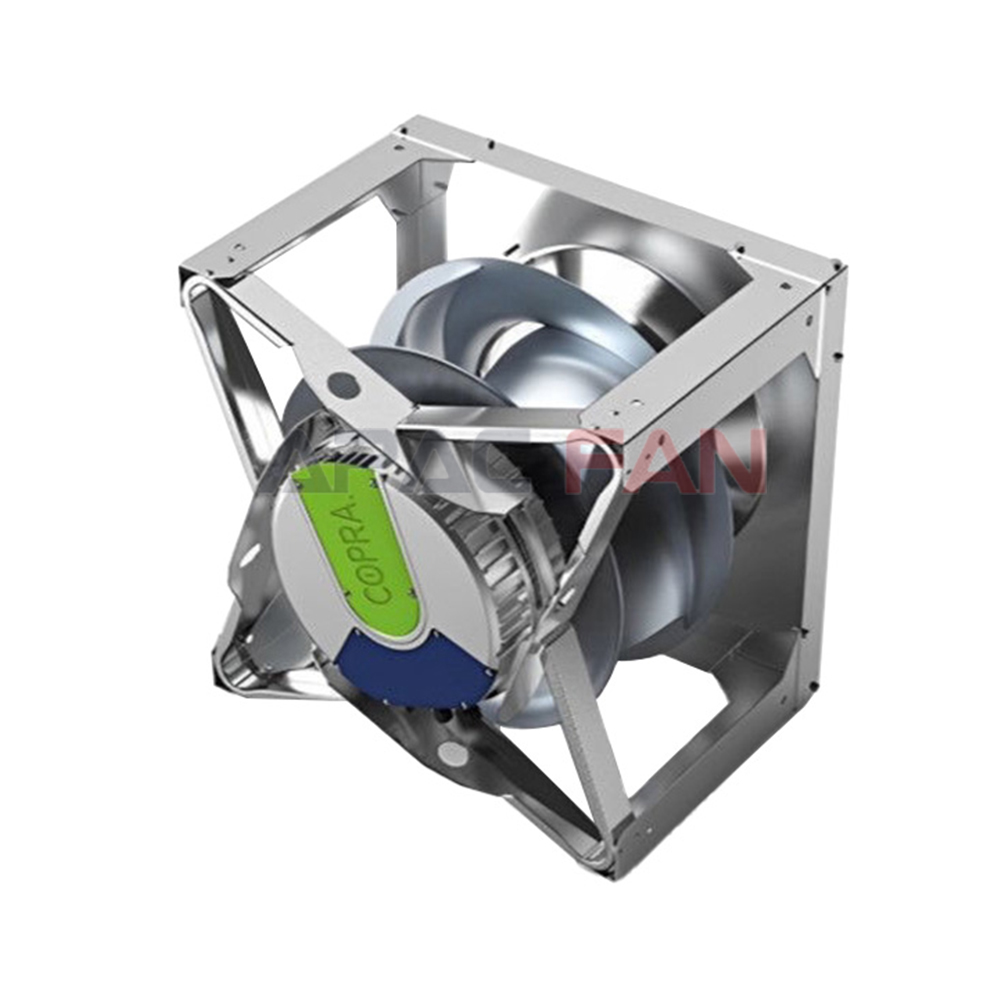

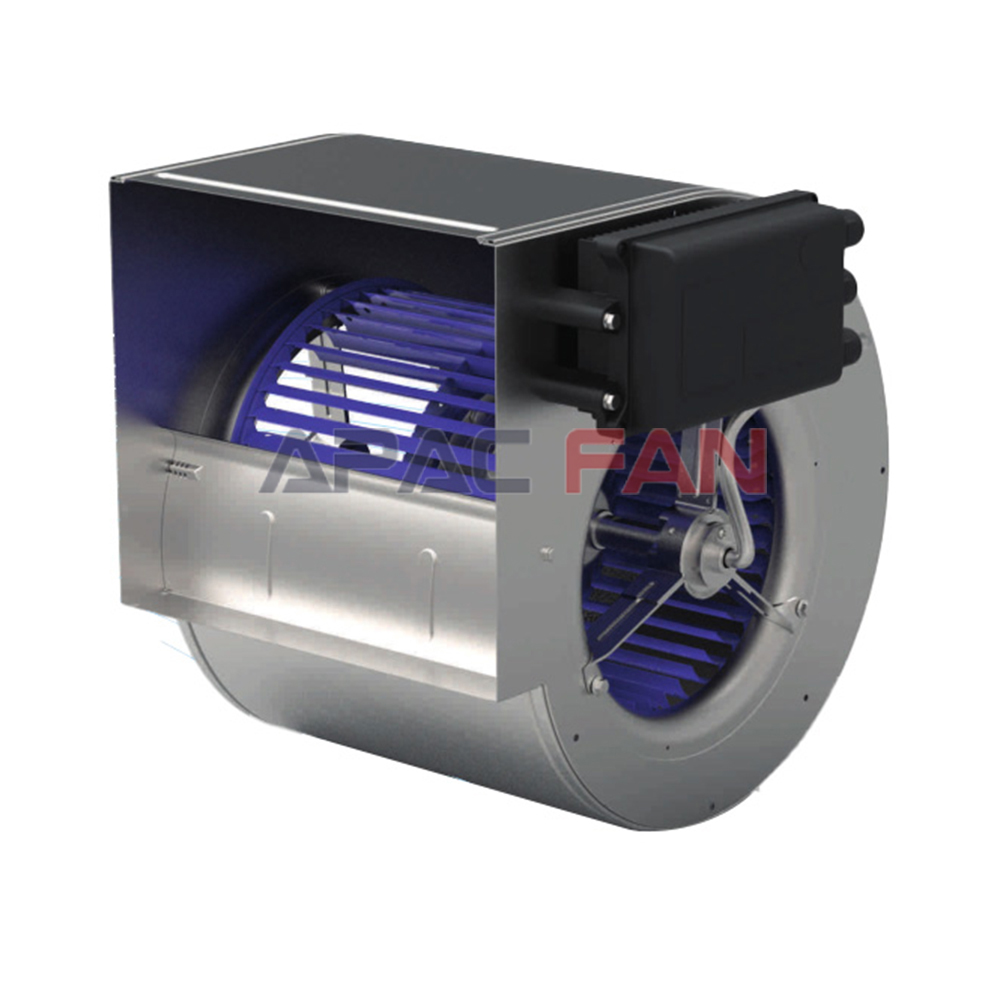

The cooling towers have been installed with 142 units of the latest-generation AxiBlade axial panel fans from ebm-papst. These fans can deliver airflows of up to 40,000 cubic meters per hour and achieve an efficiency rate of as high as 60%. Additionally, several identically designed air handling systems have been fitted with around 300 RadiCal 2 centrifugal fans. These fans come with an upgraded EC motor that not only operates more quietly but also offers higher efficiency. Moreover, these components support plug-and-play installation for ease of use and are equipped with active power factor correction (PFC) to reduce the impact of power grid outages.

30% reduction in energy consumption

The outcomes are striking: Following the retrofitting project, Capgemini has managed to cut its energy consumption by roughly 30%. Viswanathan Rajendran, Vice President of Engineering Services & Sustainability, highlights: “Equally remarkable are the technical superiority of the products and the focus on efficiency, both of which have driven significant savings.” Beyond hardware upgrades, Capgemini also leverages digital system control. Every fan is equipped with MODBUS interfaces and integrated into the Energy Command Center. This centralized monitoring system allows specialists to perform automatic, 24/7 control of the equipment. Since the ECC was set up, electricity consumption across all sites has decreased—with a 25-gigawatt-hour reduction in 2023 compared to 2019 levels.

Looking ahead, Capgemini plans to tap into even more efficiency potential with the help of artificial intelligence. Rajendran elaborates: “In partnership with ebm-papst, we aim to push the limits of innovation and advance our sustainability goals.” Both companies are counting on cutting-edge technology, data, and fresh air solutions to build a sustainable future.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文