ebm-papst RadiPac EC Centrifugal Fans Elevating Cleanroom FFU Performance

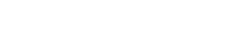

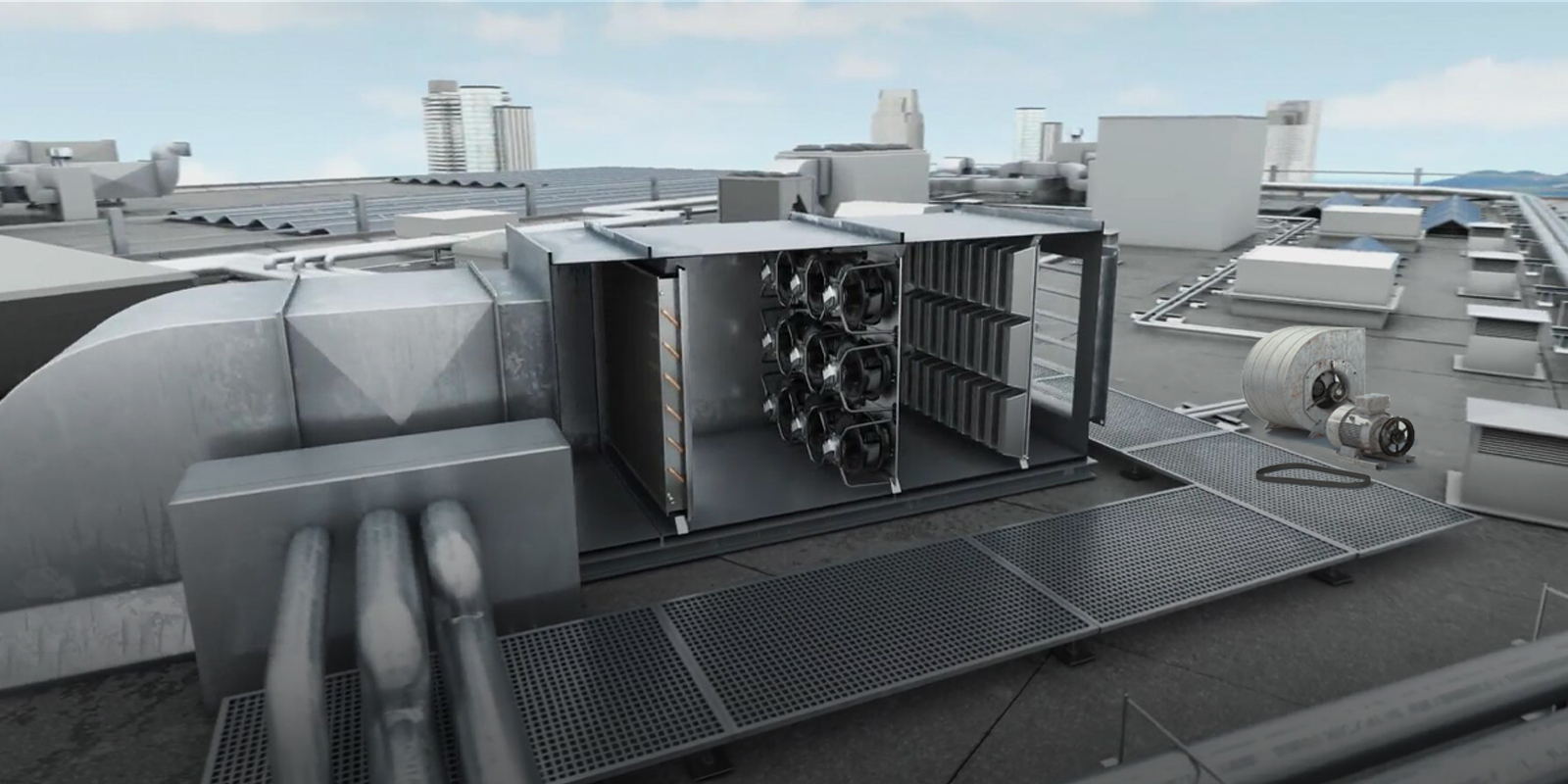

09/22/2025Cleanrooms play a critical role in numerous high-tech fields, ranging from semiconductor production and medical technology to the aerospace sector. To meet stringent standards for air purity, temperature, and humidity, filter-fan-units (FFUs)—which rely on high-efficiency fans as their core component—are employed.

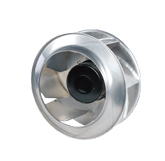

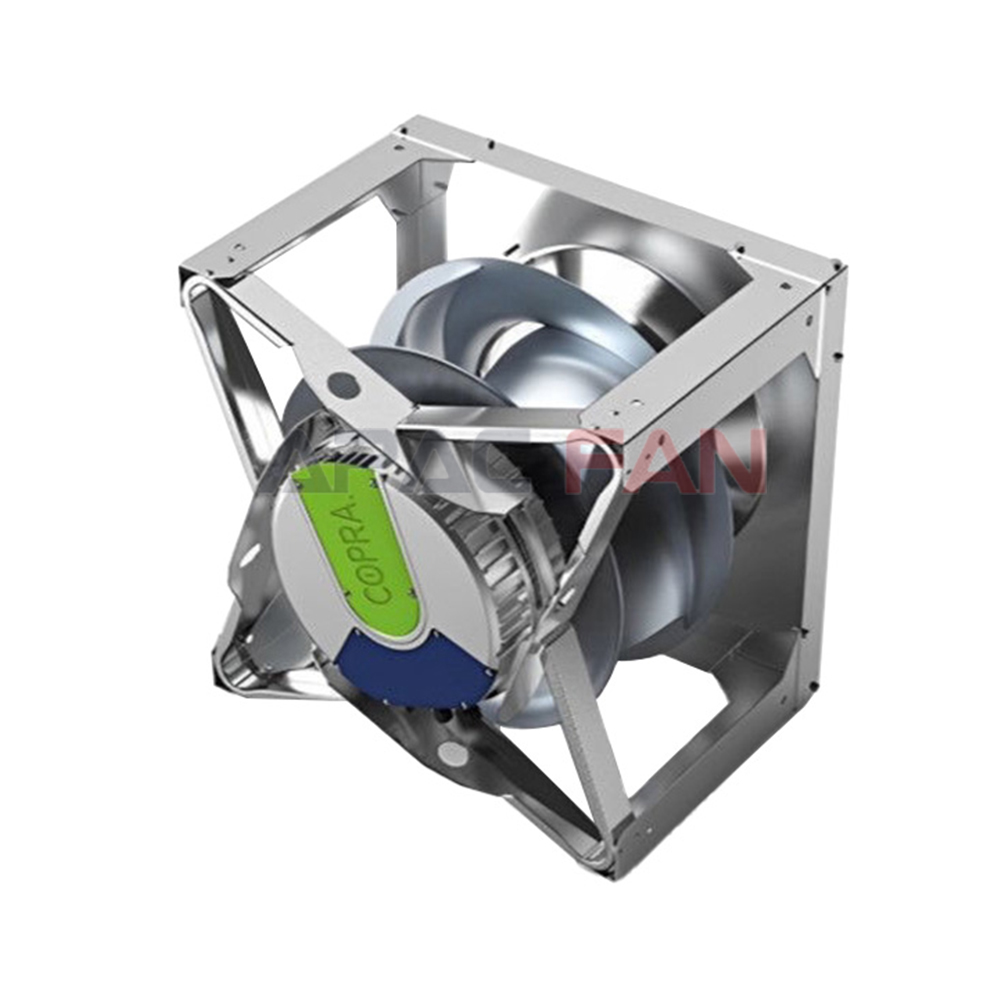

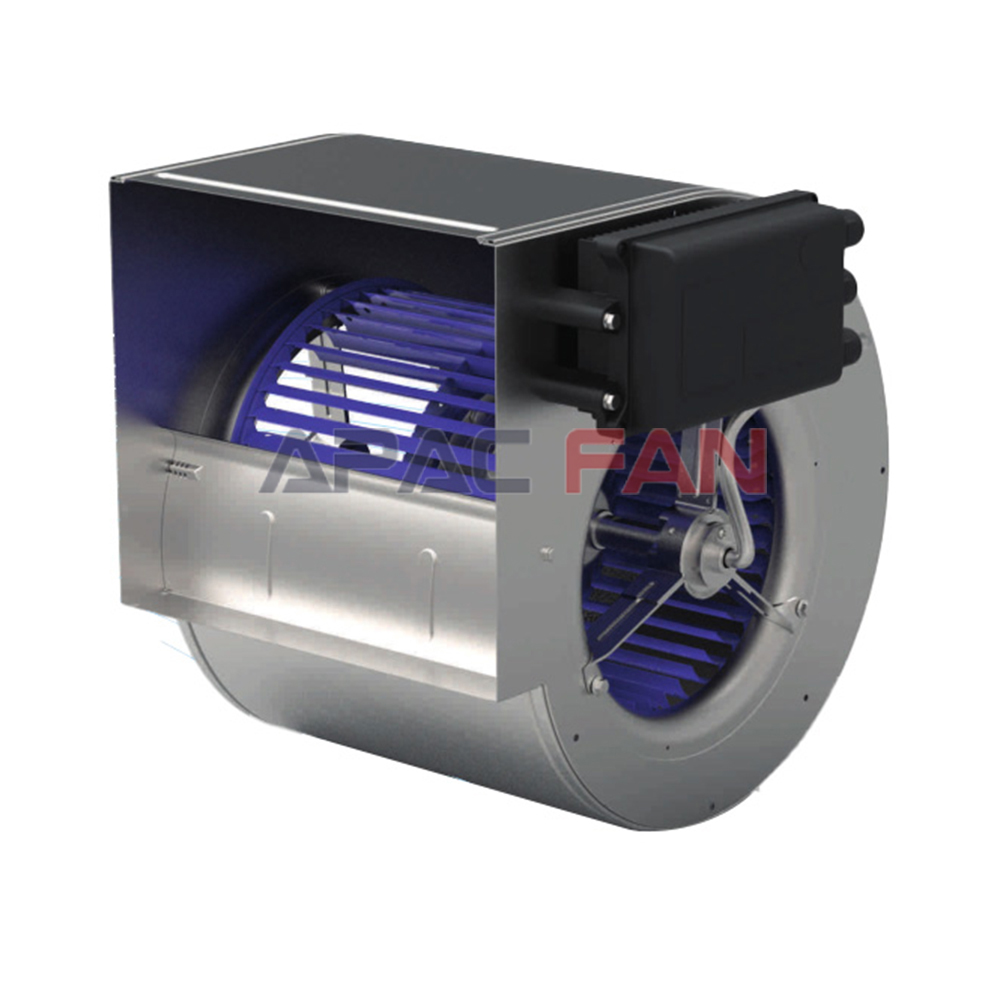

ebm-papst's new RadiPac EC centrifugal fans are a specialized solution designed for FFUs, delivering outstanding energy efficiency, low noise, and straightforward commissioning. These fans not only provide standard air volumes of up to 2,330 cubic meters per hour (with ample pressure reserves for recirculated air use in cleanrooms) but also achieve efficiency rates exceeding 60%. This is made possible by EC technology and the latest-generation RadiPac impellers. Compared to the prior industry benchmark, this translates to a 10% cut in power consumption. Additionally, they operate 6–7 decibels quieter, meeting strict noise control requirements.

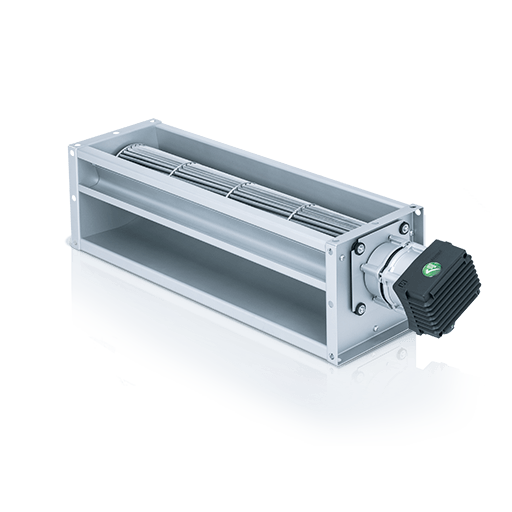

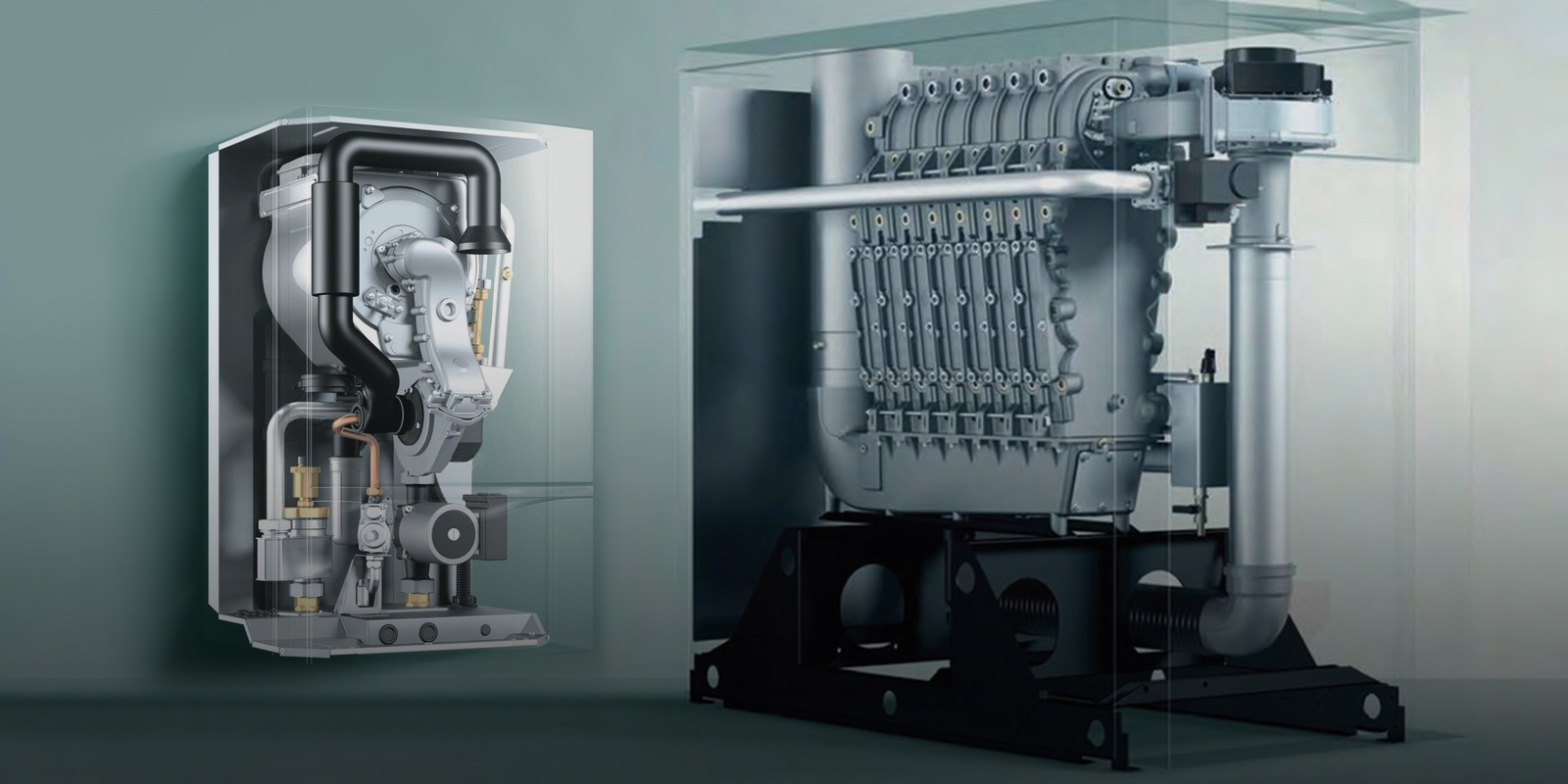

Aerodynamically Optimized Impeller Design

A key factor behind the fans' efficiency is their newly engineered impeller, featuring five aerodynamically refined blades. This design reduces both airflow losses and noise. It is paired with a customized inlet ring, plus optional add-ons like the FlowGrid air-inlet guard—this accessory minimizes air turbulence while also preventing accidental contact.

High-Performance EC Motors

The fans integrate 170–500 watt EC motors that are compact, powerful, and custom-matched to each specific fan. A modern MODBUS RTU interface (equipped with automated DCI addressing, or daisy chain interface) allows for fast, error-free integration into automation systems. Addresses are assigned automatically via a hardware signal, saving time and costs during commissioning—especially for large-scale FFU setups.

Global Applicability

RadiPac fans are available as complete plug-and-play units or individual components. With installation depths of just 190–275 mm and diameters of 280–400 mm, they are well-suited for space-constrained installation environments and retrofitting projects. They comply with all relevant international cleanroom standards, support global use, and are built to be future-proof.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文