Exploration of AHU Technology in Commercial Building Energy Conservation

11/12/2025In the global energy consumption and carbon emission structure, the construction sector has always accounted for a significant proportion, making it a key area that needs breakthroughs in achieving low-carbon development goals. To promote the transformation of the construction industry towards low-carbonization and high efficiency, various building energy conservation policies and implementation rules have been continuously introduced, focusing on standardization, technology promotion, and incentive mechanisms. The aim is to reduce the whole-life-cycle energy consumption of buildings, improve energy efficiency, and lay a solid foundation for sustainable development strategies.

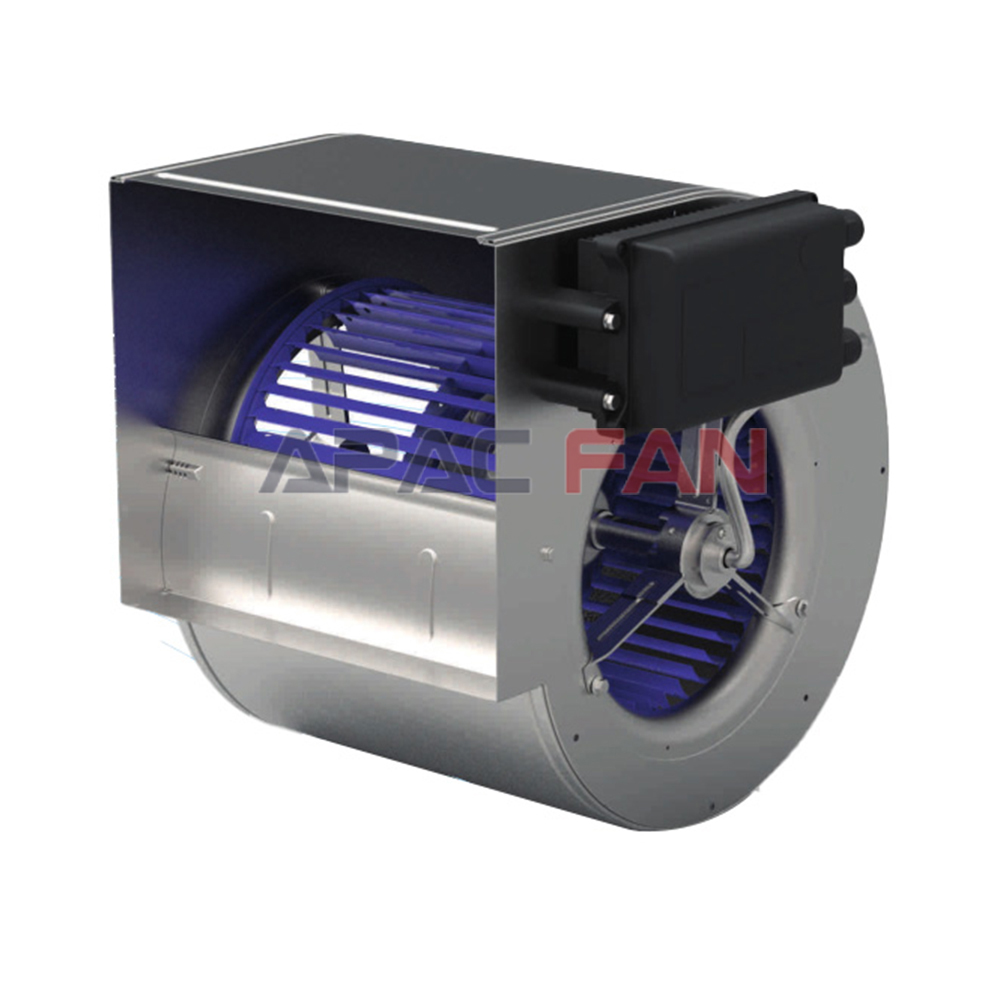

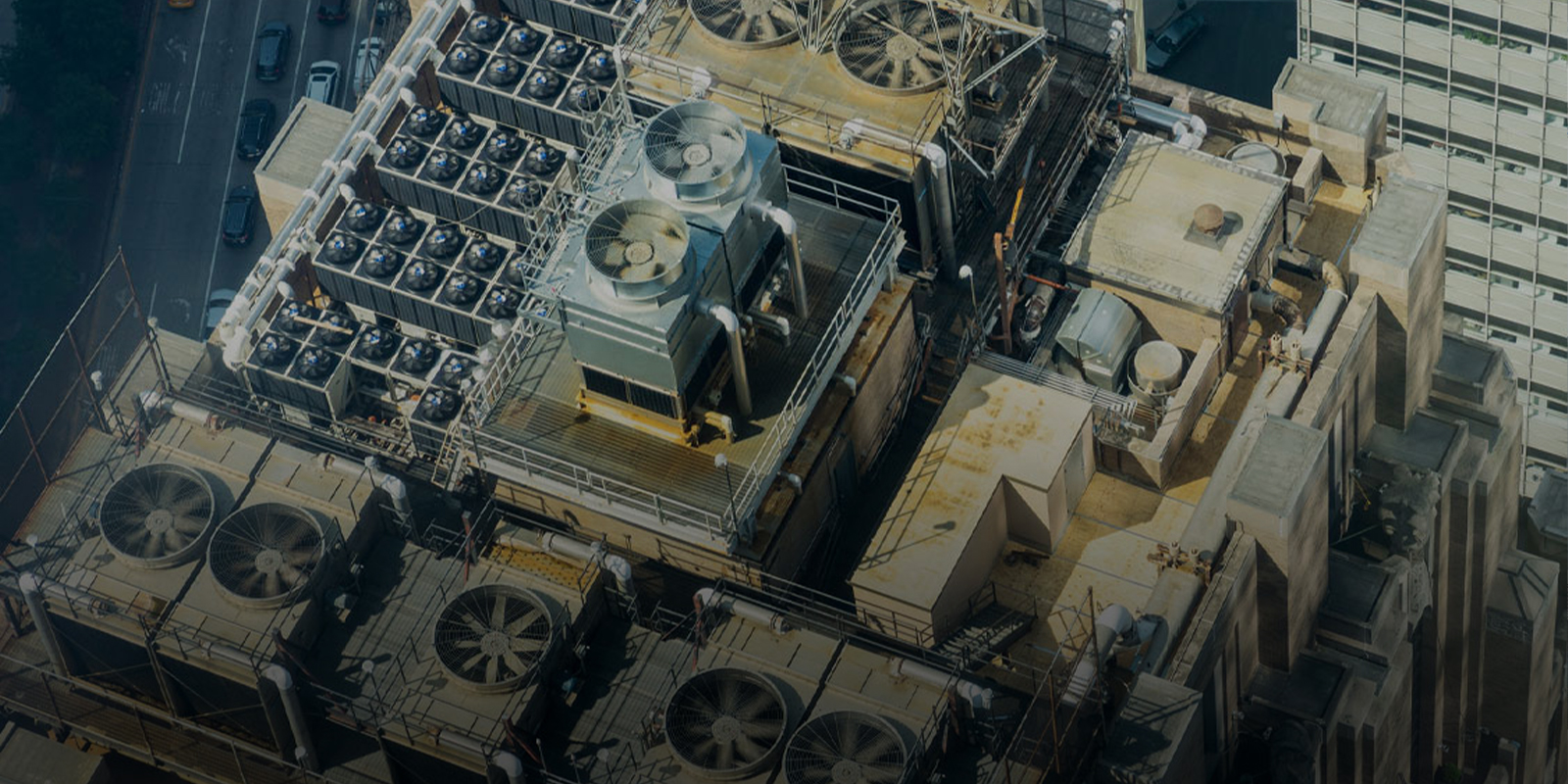

In the composition of total building energy consumption, HVAC (Heating, Ventilation, and Air Conditioning) systems account for 40% to 50%. Their energy-saving performance directly determines the path to achieving building low-carbon goals. As a core equipment in HVAC systems, Air Handling Units (AHU) rely on centralized air treatment capabilities to accurately adjust indoor temperature, humidity, and air cleanliness according to the needs of commercial buildings. They are widely used in large commercial scenarios such as shopping malls, exhibition halls, and airport terminals. Among the numerous components of AHU, fans, as the power core, have a decisive impact on the overall energy efficiency of commercial buildings, becoming a key breakthrough for AHU energy-saving optimization.

AHU Performance Requirements Under Green Building Standards

Green buildings put forward multi-dimensional requirements for the design and operation of AHU, with the core goal of achieving efficient energy use and environmental friendliness while ensuring indoor environmental quality:

High Energy Efficiency: Optimize the energy efficiency of core AHU components (such as fans, heat exchangers, and filters) to minimize operating energy consumption and carbon emissions, ensuring that equipment performance meets the energy efficiency requirements in green building evaluation systems.

Intelligent Control Capability: Equip with intelligent control systems with real-time adjustment functions. Dynamically adjust operating modes (such as air volume and water temperature) according to actual needs such as indoor personnel density and indoor-outdoor temperature and humidity changes to achieve precise optimization of energy use and avoid ineffective energy consumption.

Adaptability and Flexibility: Adopt a modular design concept where functional components can be flexibly combined. It can adapt to the structural characteristics and space constraints of different commercial buildings, and facilitate equipment expansion, maintenance, or technical upgrading according to later usage needs, reducing whole-life-cycle costs.

Reliability and Stability: Possess the ability to operate continuously and stably for a long time. Reduce energy waste and operational losses caused by shutdowns due to failures or maintenance through optimizing equipment structure and selecting durable components, ensuring continuous comfort of the building environment.

Low-Noise Design: Reduce operating noise through optimizing air flow paths, using noise-reducing materials, and improving component assembly precision during equipment design and manufacturing. Avoid interference with indoor office, commercial activities, and the surrounding environment, balancing functionality and comfort.

Application Advantages of ebm-papst RadiPac Centrifugal Fans in AHU

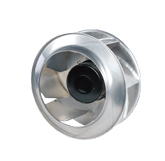

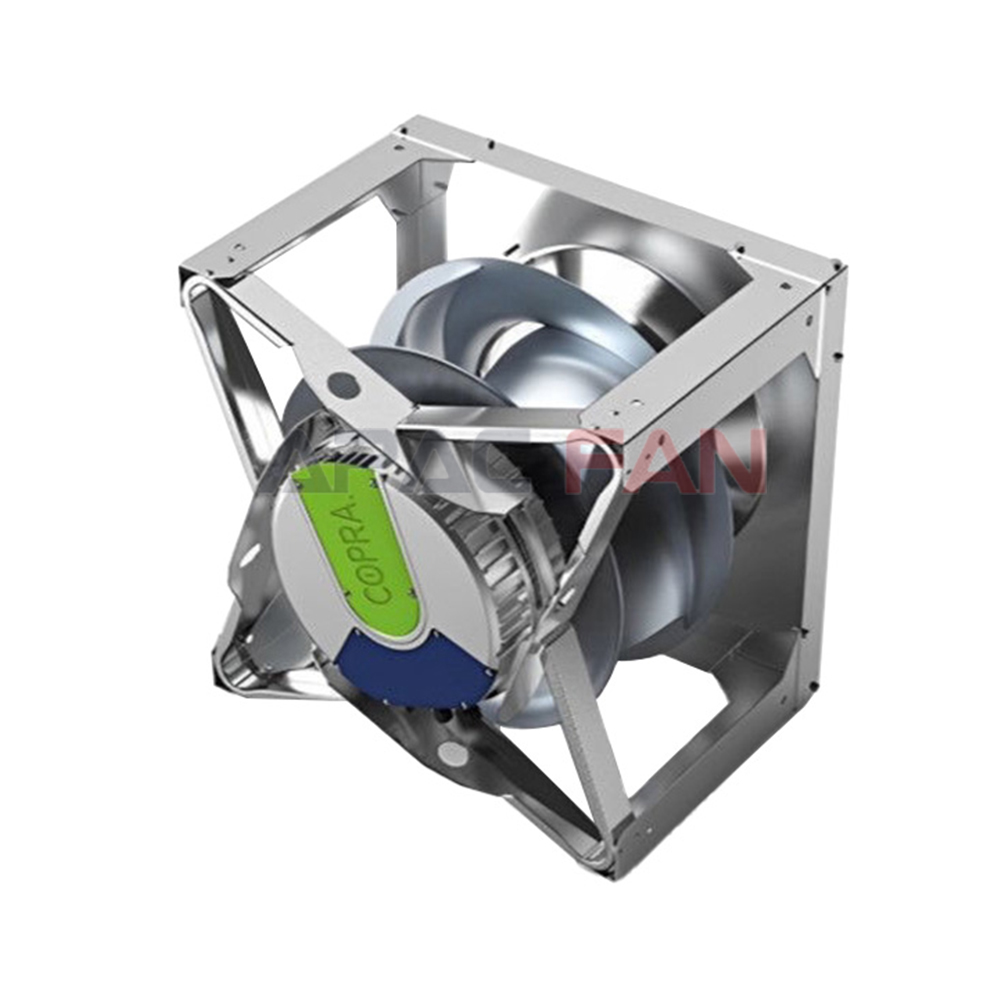

As a high-efficiency fan product meeting green building needs, the ebm-papst RadiPac series centrifugal fans demonstrate multiple performance advantages in AHU applications, providing strong support for commercial building energy conservation:

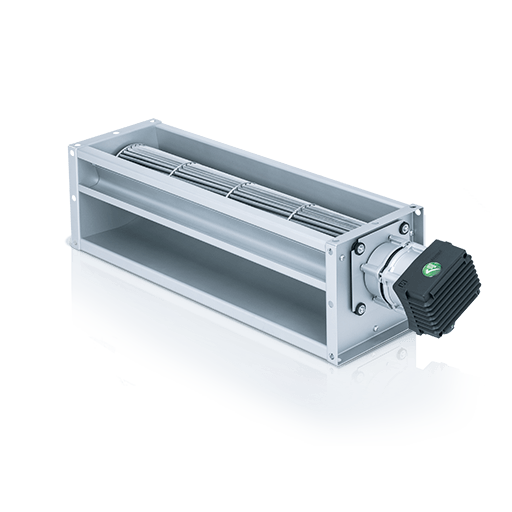

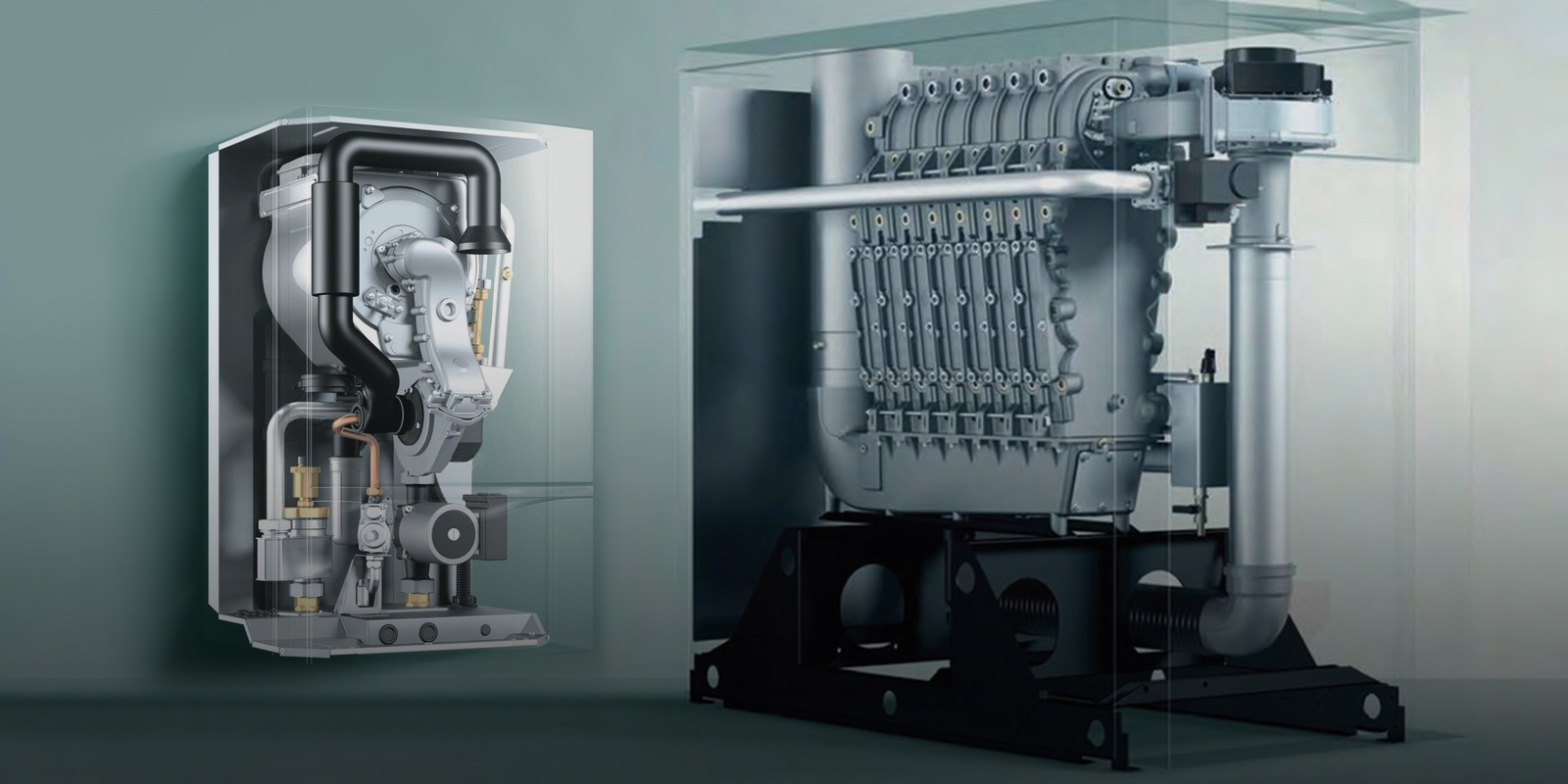

Ultra-High Energy Efficiency, Reducing Operational Costs: The RadiPac series integrates high-efficiency EC motor technology, aerodynamic optimization design, innovative lightweight materials, and precision manufacturing processes, enabling the system to achieve a maximum efficiency exceeding 70%. This energy efficiency level not only significantly reduces energy consumption during AHU operation but also directly lowers the long-term operational costs of commercial buildings, highly aligning with building energy conservation and sustainable development goals.

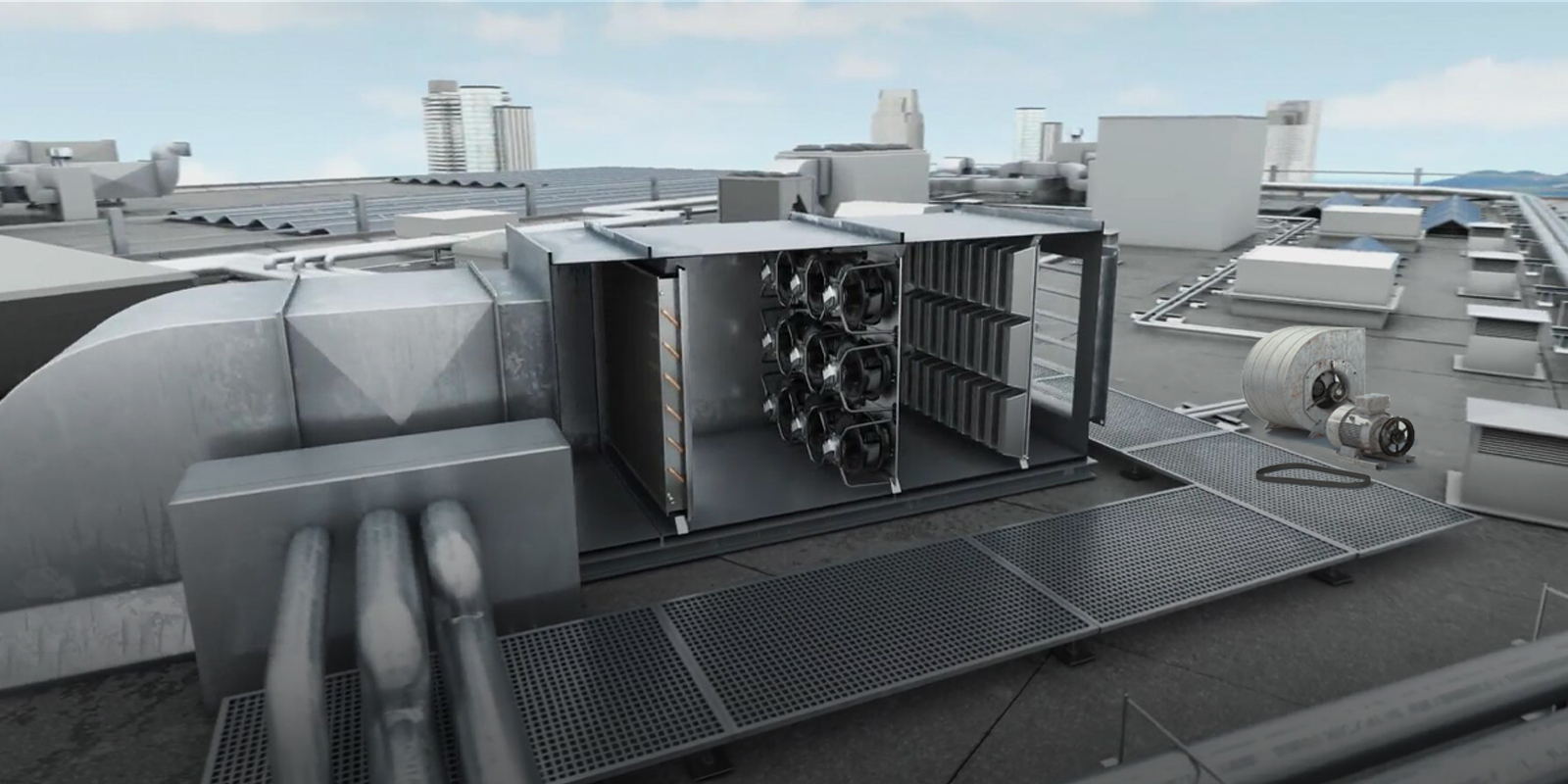

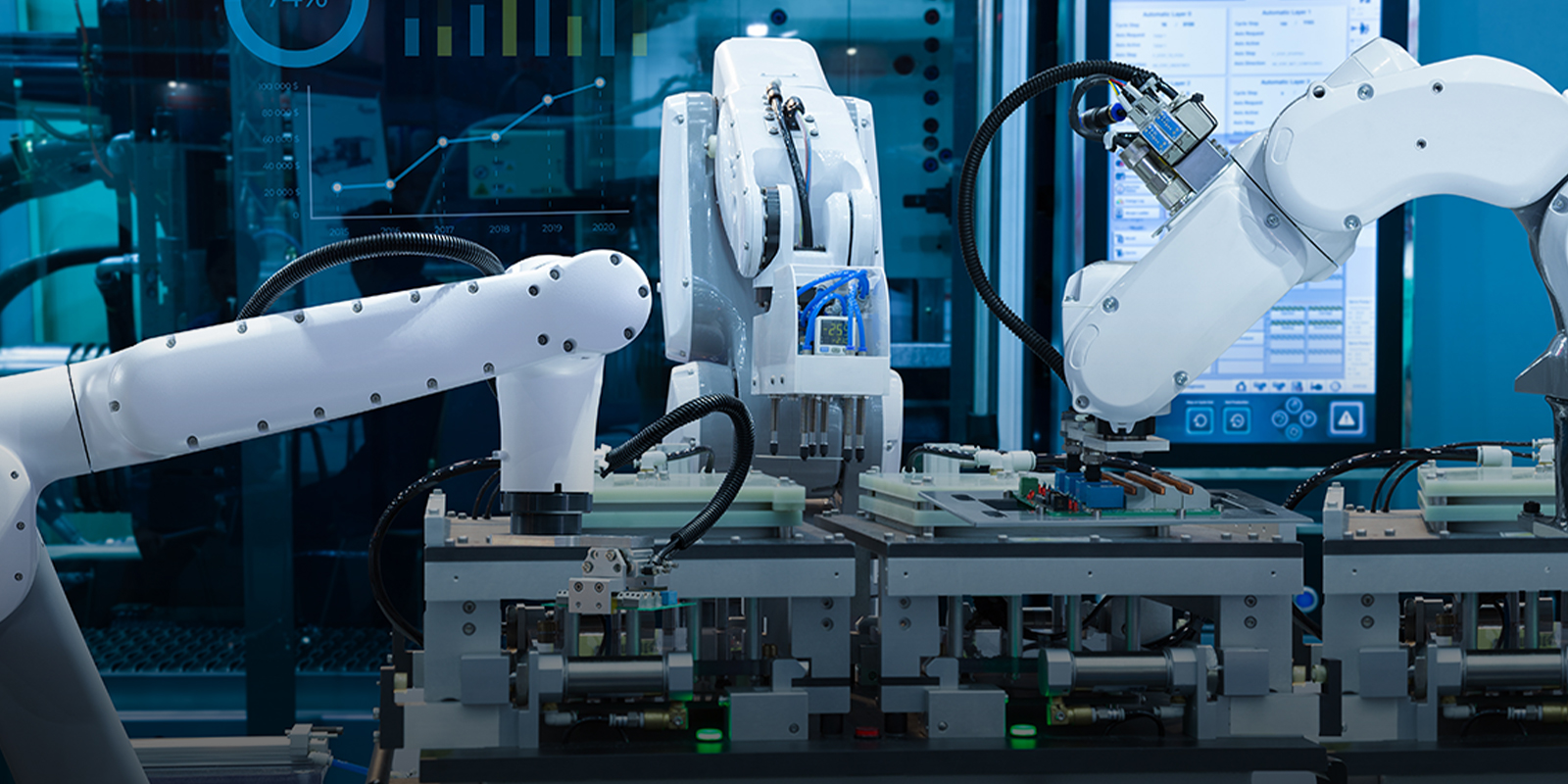

Intelligent Linkage, Optimizing System Performance: The fans are equipped with configurable control interfaces supporting analog and digital signals. They can adjust fan speed and air volume in real time according to the actual usage scenarios of commercial buildings (such as peak/off-peak passenger flow and functional needs of different areas). Meanwhile, the series can be seamlessly integrated with Building Management Systems (BMS) to achieve centralized intelligent control and operation status monitoring, further improving the overall energy efficiency of the AHU system through dynamic optimization of operating parameters.

Stability and Durability, Extending Equipment Lifespan: To meet the durability requirements of core fan components, the RadiPac series offers an optional resonance detection function. It can real-time monitor resonance risks during equipment operation and adjust operating status to prevent premature bearing wear, effectively avoiding system failures caused by component damage, significantly extending fan service life, and reducing equipment maintenance frequency and replacement costs.

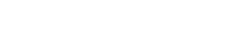

Compact Design, Saving Equipment Room Space: The series adopts an integrated design of high-performance impellers and external rotor motors, greatly reducing the overall equipment volume and making the structure more compact. This design not only reduces the space occupied by AHU units but also indirectly lowers the construction area demand for commercial building equipment rooms, providing more flexibility for building space planning and saving equipment room construction costs.

Modular Assembly, Improving Construction Efficiency: Multiple RadiPac plug-and-play fans can be combined to form a FanGrid system. The modular design makes installation more flexible, fast, and simple, eliminating the need for complex on-site commissioning, effectively shortening the construction period, reducing labor input, and lowering time and labor costs during the project construction phase.

Quiet Operation, Ensuring Environmental Comfort: Under the same operating conditions and working points, the noise level of the new RadiPac series is 3-7 dB(A) lower than that of the previous generation. Lower operating noise can effectively improve the comfort of the indoor environment in commercial buildings, avoiding interference with shopping, office work, exhibition displays, and other activities, achieving a balance between equipment functionality and environmental experience.

In summary, as a core equipment in the HVAC systems of commercial buildings, the energy-saving performance of AHU is directly related to the achievement of building low-carbon goals. Requirements such as high energy efficiency, intelligent control, and flexible adaptation under green building standards are driving technological innovation of core AHU components. With multiple advantages including high efficiency, intelligence, and compactness, the ebm-papst RadiPac series centrifugal fans perfectly meet the energy-saving needs of modern commercial buildings, providing a practical technical solution for the construction industry to reduce energy consumption and carbon emissions. In the future, with the continuous iteration of energy-saving technologies, AHU systems will develop towards a more efficient, intelligent, and environmentally friendly direction, injecting stronger momentum into the global sustainable development of buildings.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文