ebm-papst Joins Forces with Siemens to Drive Digital Transformation

10/09/2025The collaboration will focus on developing ebm-papst’s global engineering environment using Siemens’ Teamcenter®—a PLM software from the Siemens Xcelerator industrial software suite—aimed at advancing its digital transformation and setting new global PLM standards. This platform will boost cross-location collaboration, enable customized product delivery via new digital business models, and support technologies like digital twins and AI. Executives from both firms highlight shared expertise in driving agile, efficient product development and industry innovation.

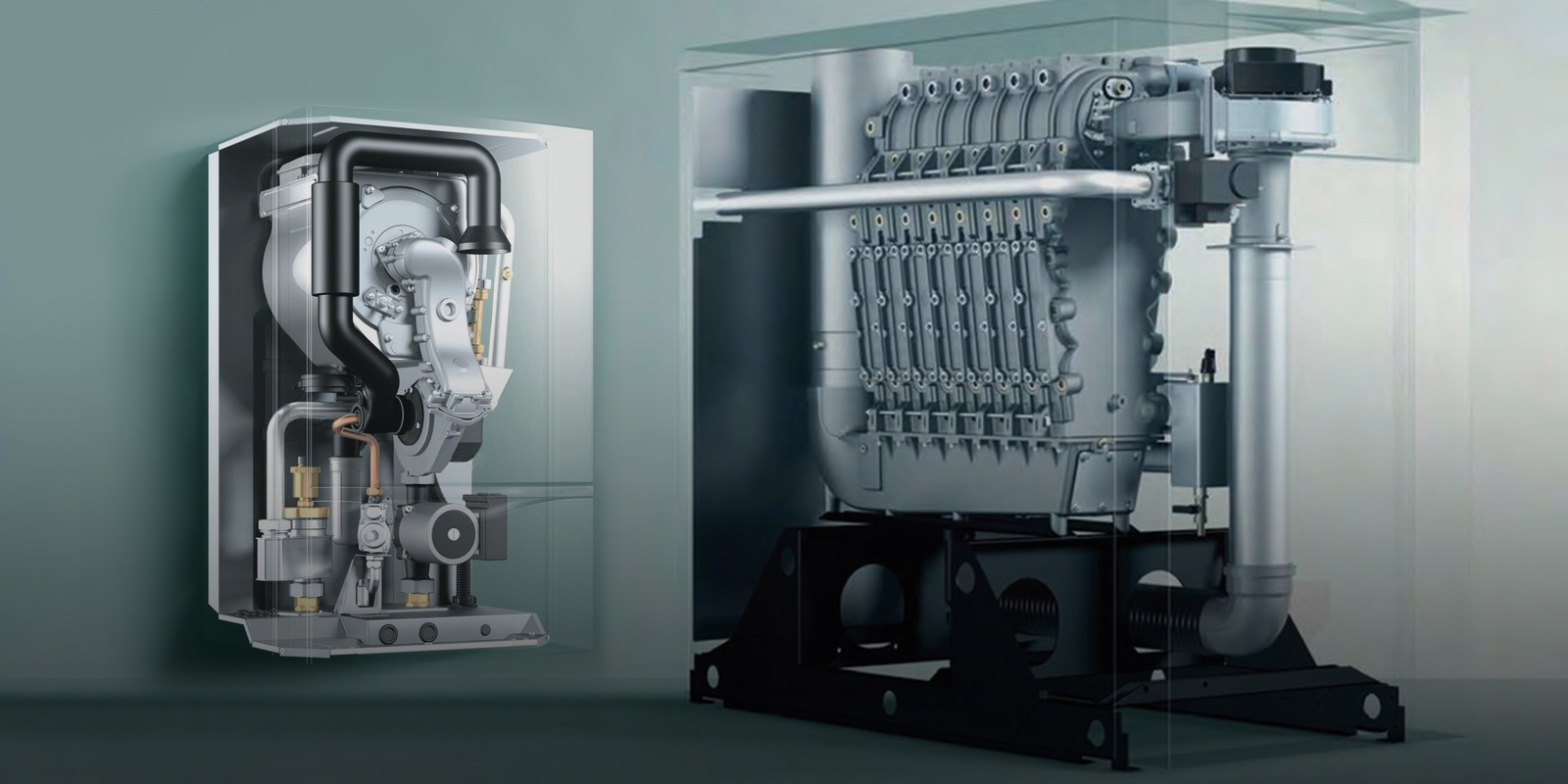

ebm-papst has announced a long-term strategic partnership with Siemens AG to advance its digital transformation and create a next-generation global engineering environment. Over the coming years, the two companies will collaborate to build ebm-papst’s worldwide engineering system, leveraging Siemens’ Teamcenter® software—a Product Lifecycle Management (PLM) solution part of the Siemens Xcelerator industrial software portfolio. The goal is to establish a new benchmark for global PLM as a core part of ebm-papst’s digital transformation efforts.

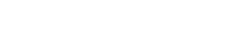

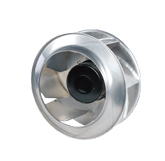

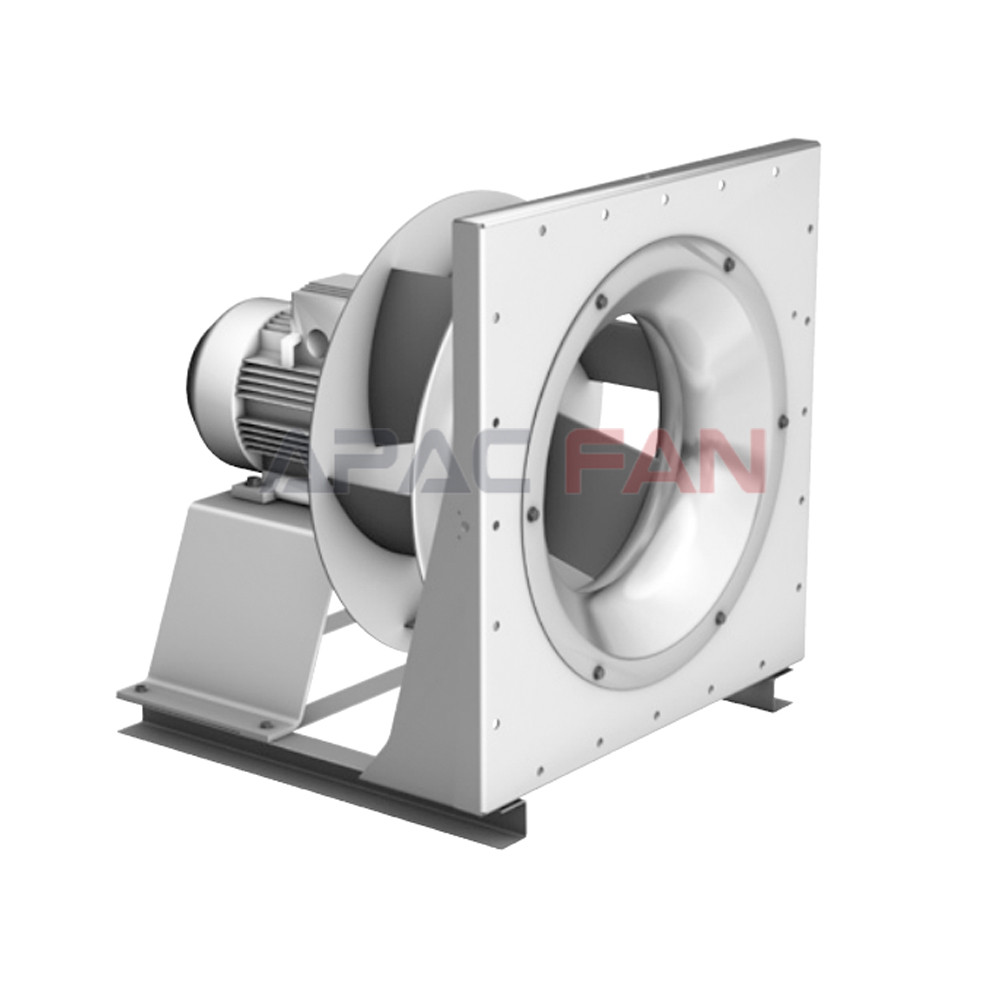

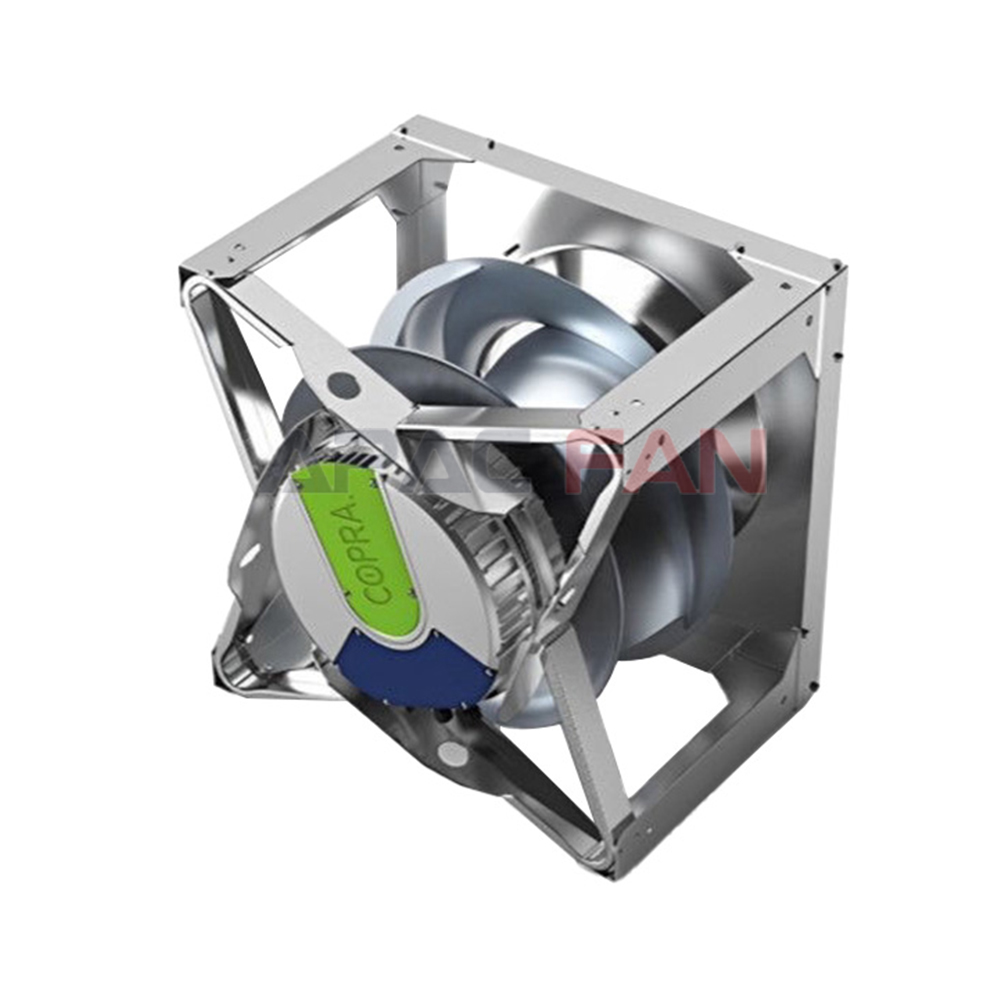

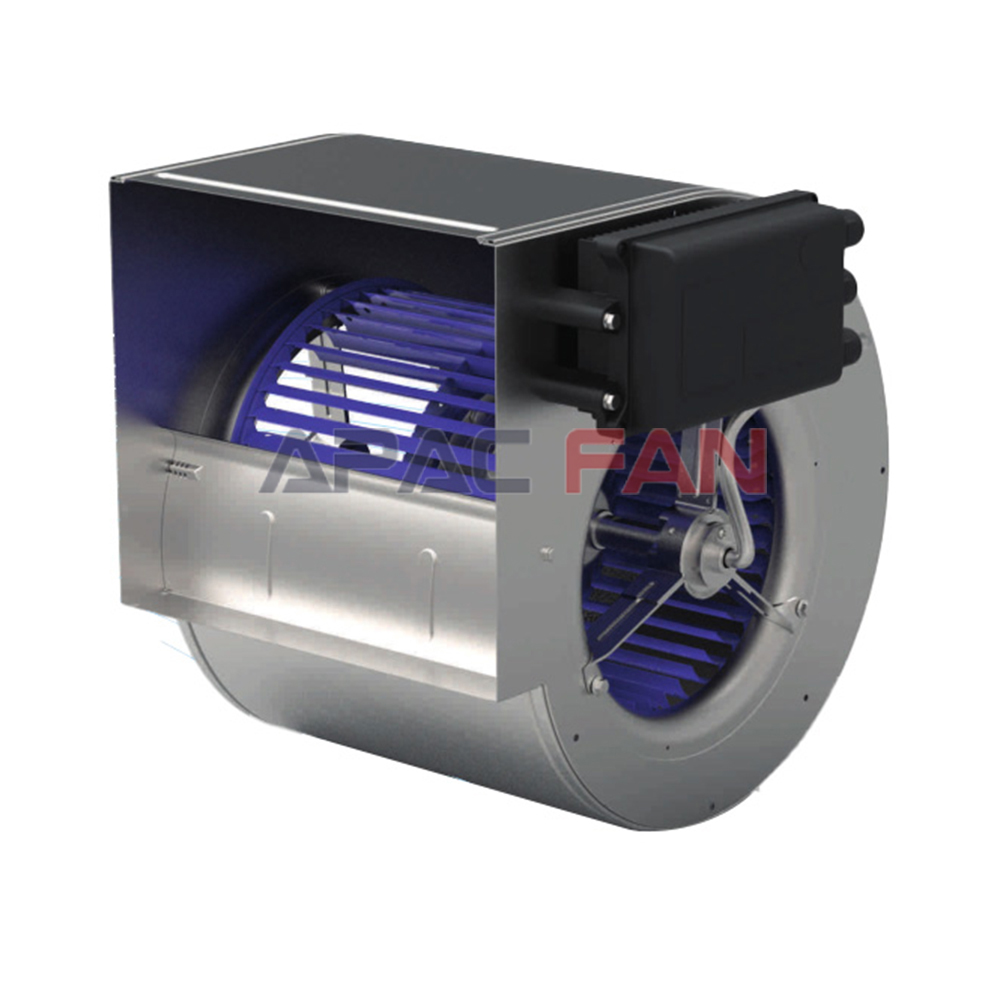

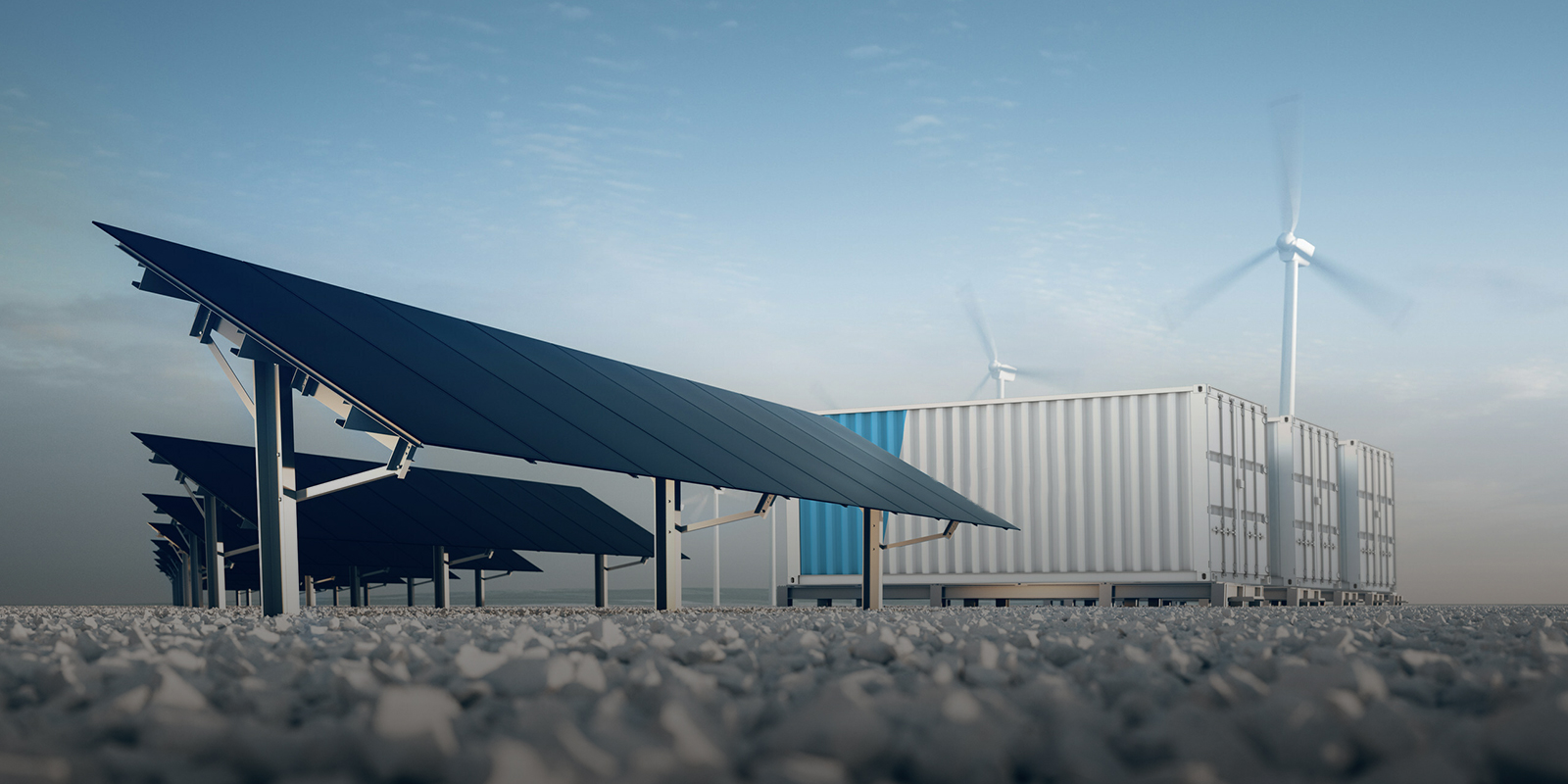

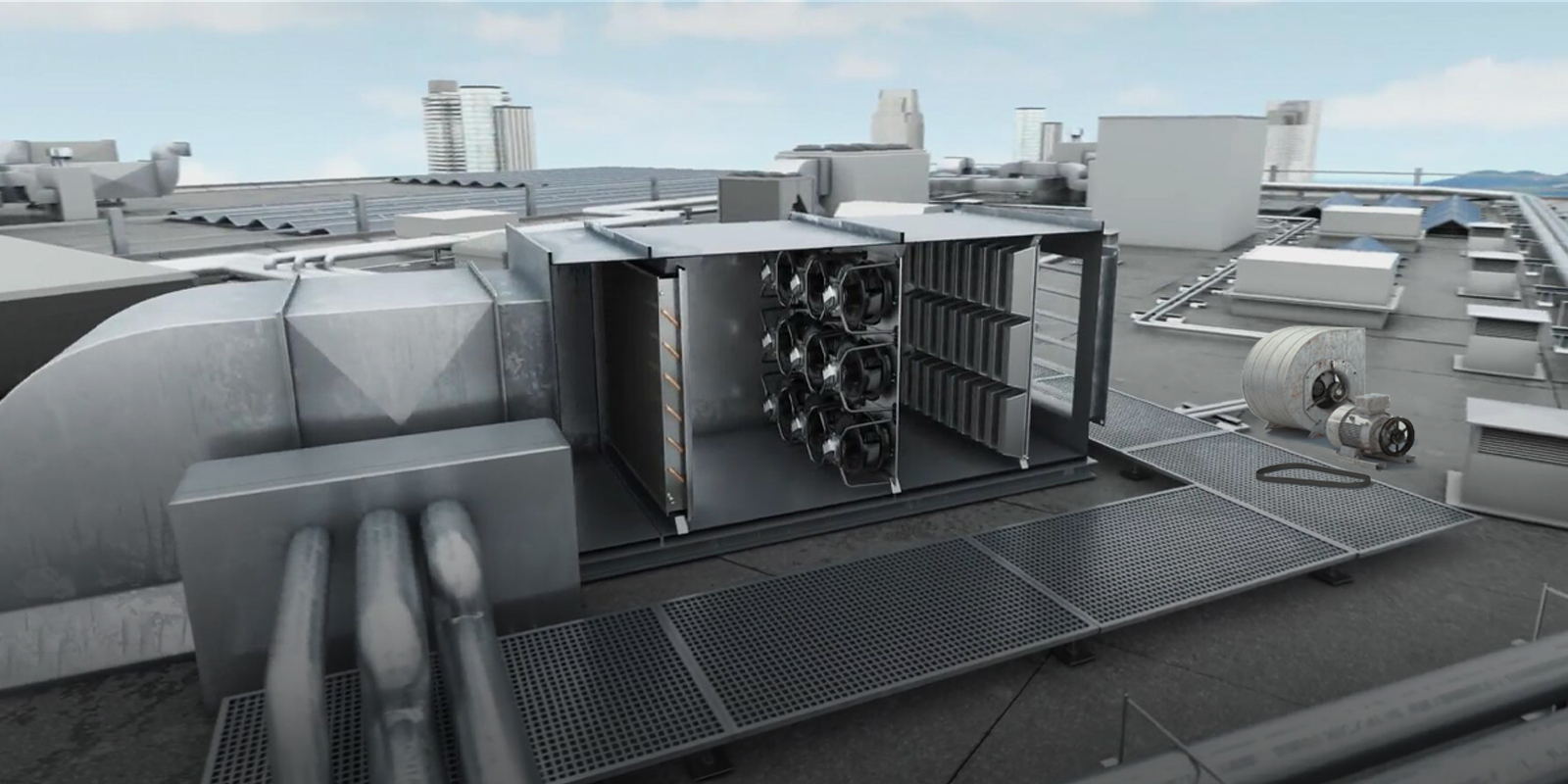

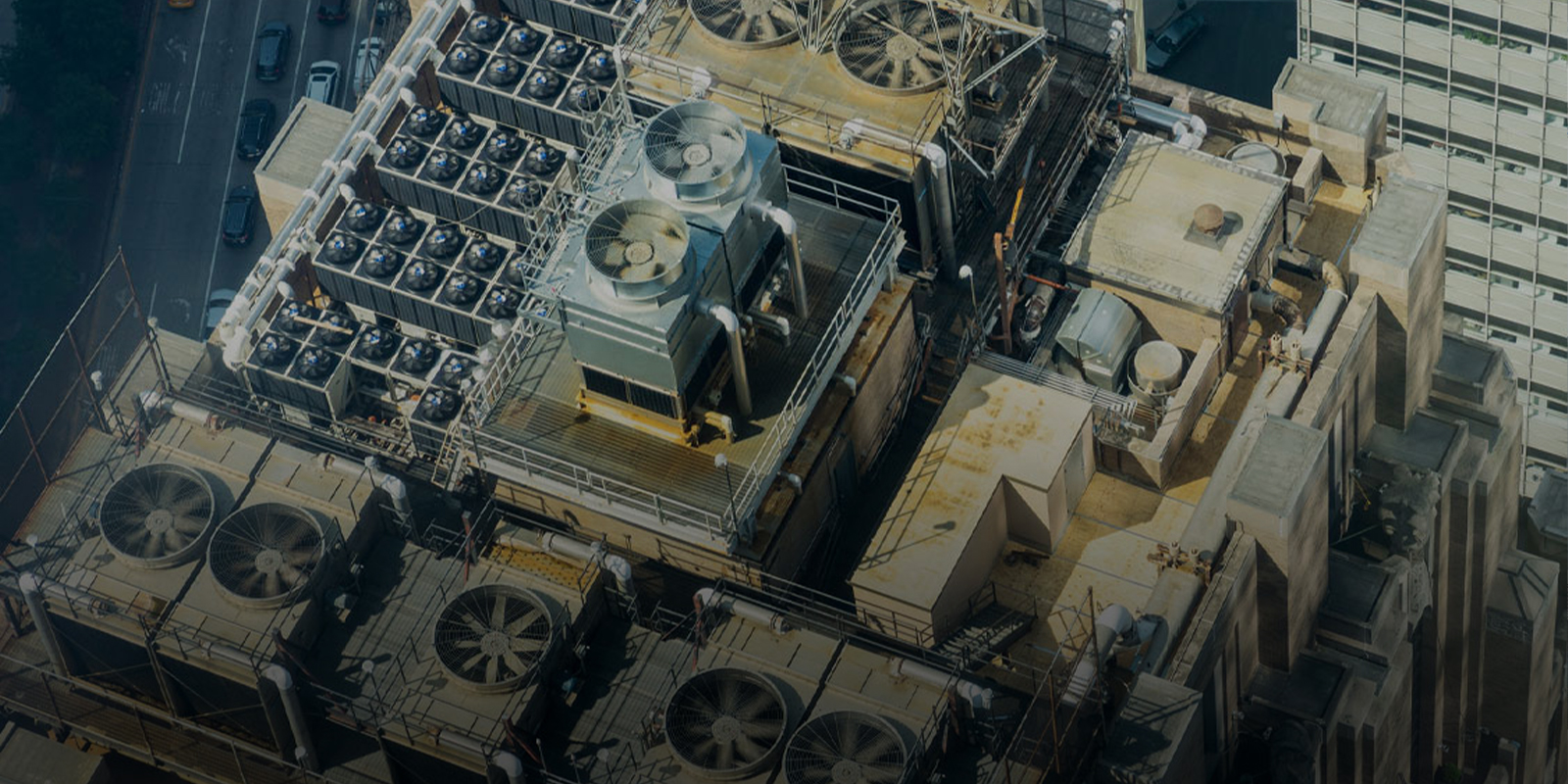

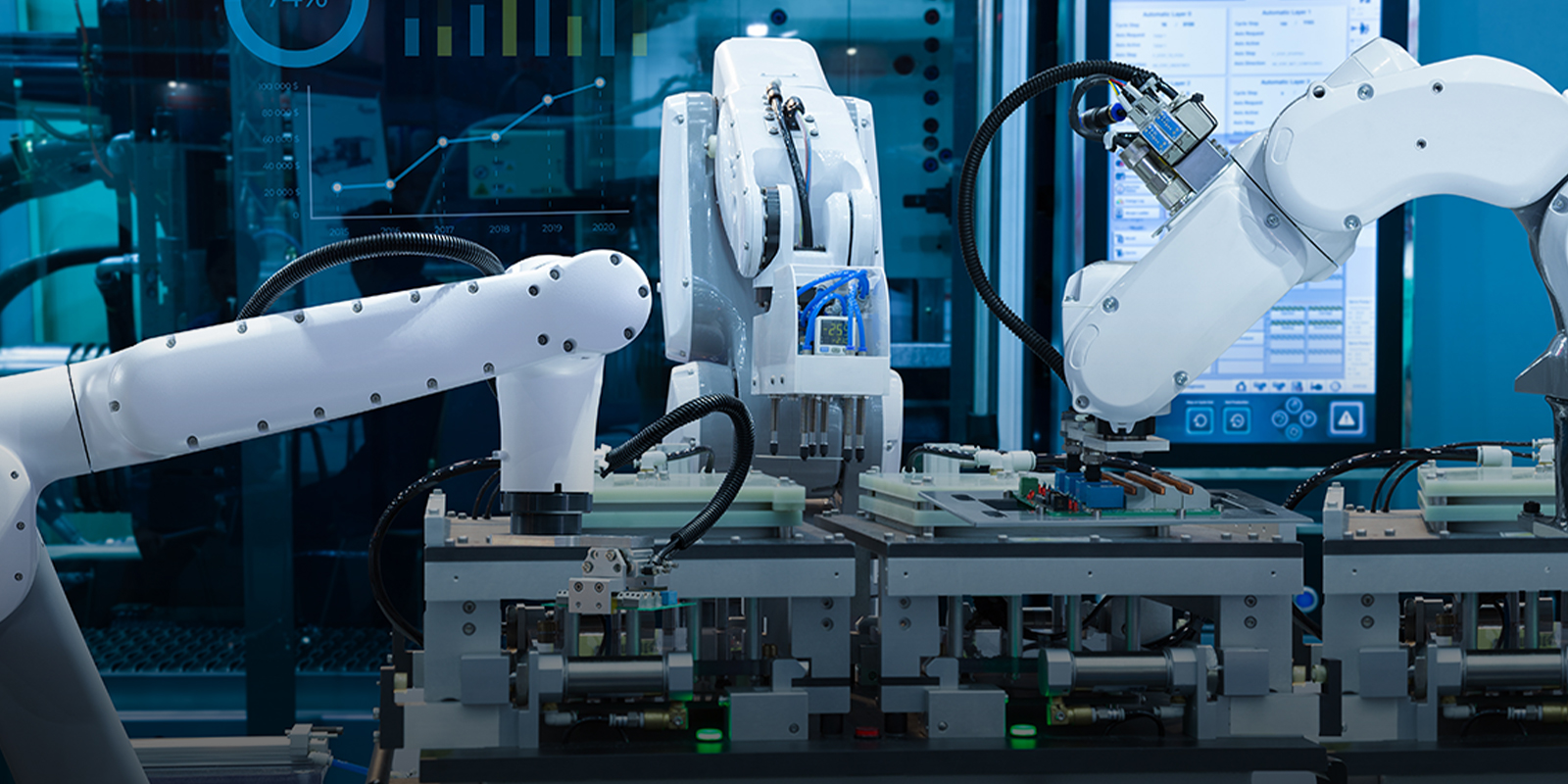

As a leading global producer of fans and motors, ebm-papst expects the adoption of Teamcenter and the launch of this global PLM platform to support the development of new digital business models. These models will allow the company to deliver more customized products and solutions to its customers, while the company-wide PLM system will also enhance collaboration across all of ebm-papst’s global locations.

Klaus Geißdörfer, CEO of ebm-papst, stated: “Our strategic work with Siemens lets us implement standardized processes across our global operations. We’re not just using cutting-edge digital tools—we’re also tapping into Siemens’ expertise as a market leader in PLM software.”

Frances Evans, Senior Vice President of Lifecycle Collaboration Software at Siemens Digital Industries Software, commented: “Digital transformation, fueled by Siemens Xcelerator, is helping innovators in many industries rethink their key business processes and unlock new opportunities for their customers. It’s exciting to see an industry pioneer like ebm-papst use Teamcenter to transform how it brings new products to market. We’re eager to partner with their team to help them achieve their goals.”

Tomas Smetana, CTO of ebm-papst, emphasized: “Product Lifecycle Management is the foundation for transparent, efficient, and—most importantly—agile product development. Siemens is supporting us in reaching these objectives with its PLM software, which is a key component of our company’s digital transformation.”

As an engineering-focused business, ebm-papst aims to develop high-quality products and solutions that meet customers’ unique needs. For success in the market, two factors are critical: reducing the time from customer inquiry to product delivery, and using modular systems efficiently to create cost-effective solutions. Achieving this requires comprehensive, well-coordinated, and fully standardized processes.

Through its global PLM platform, ebm-papst plans to establish exactly these standards—covering every stage from strategy, product requirements, and architecture to design, simulation, validation, and final product delivery. Key technology areas, such as building digital twins and integrating artificial intelligence, will play a vital role here—especially as the company explores new digital business models, customer services, and applications.

This partnership also presents Siemens with an opportunity to strengthen its position as a PLM market leader by setting another industry benchmark. ebm-papst is adopting a full suite of Siemens software and has high expectations for the solution, which means Siemens can contribute its latest innovations as part of the collaboration. Klaus Geißdörfer added: “ebm-papst and Siemens both bring top-tier technical expertise to this partnership. This lets us learn from each other and collaborate on advancing cutting-edge technologies like AI, digital twins, and model-based system engineering.”

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文