How to Cool Down Wind Turbines in Hot Summer?

09/18/2025In summer, people rely on fans to dispel heat, but have you ever wondered how to cool down large equipment when it "heats up" itself?

In wind farms, large wind turbines are like living entities, with core components similar to a "torso", "heart" and "nerve center". Nowadays, as the installed capacity of wind power continues to rise, the heat dissipation pressure of these core equipment is also increasing day by day - if the waste heat generated during operation cannot be discharged in time, the stable operation of the equipment will be seriously affected. From nacelles, generators, control cabinets to converters and transformers, ebm-papst, relying on a variety of energy-saving EC fans, has created a diversified heat dissipation solution covering axial and centrifugal fans for the wind power industry, helping wind farms efficiently solve heat dissipation problems.

The operation of wind turbines depends on wind energy, so they cannot work continuously around the clock. When the power generation of a wind farm decreases, or even when there is no power output, the cooling demand of the equipment will also decrease accordingly. The energy-saving EC fans of ebm-papst have a stepless speed regulation function, which can accurately adjust their own operation status according to the actual cooling needs of the equipment, truly achieving high efficiency and energy saving. At the same time, the design optimized by aerodynamics allows the fan to maintain a low-noise mode during operation. This feature is undoubtedly of great significance for wind farms near residential areas. In addition, in harsh environments such as high salt spray and high humidity, equipment components are prone to corrosion and aging. However, ebm-papst fans use special coatings, which can reach up to the C5-M anti-corrosion grade in the DIN EN ISO 12944 standard, effectively coping with the challenges of harsh environments.

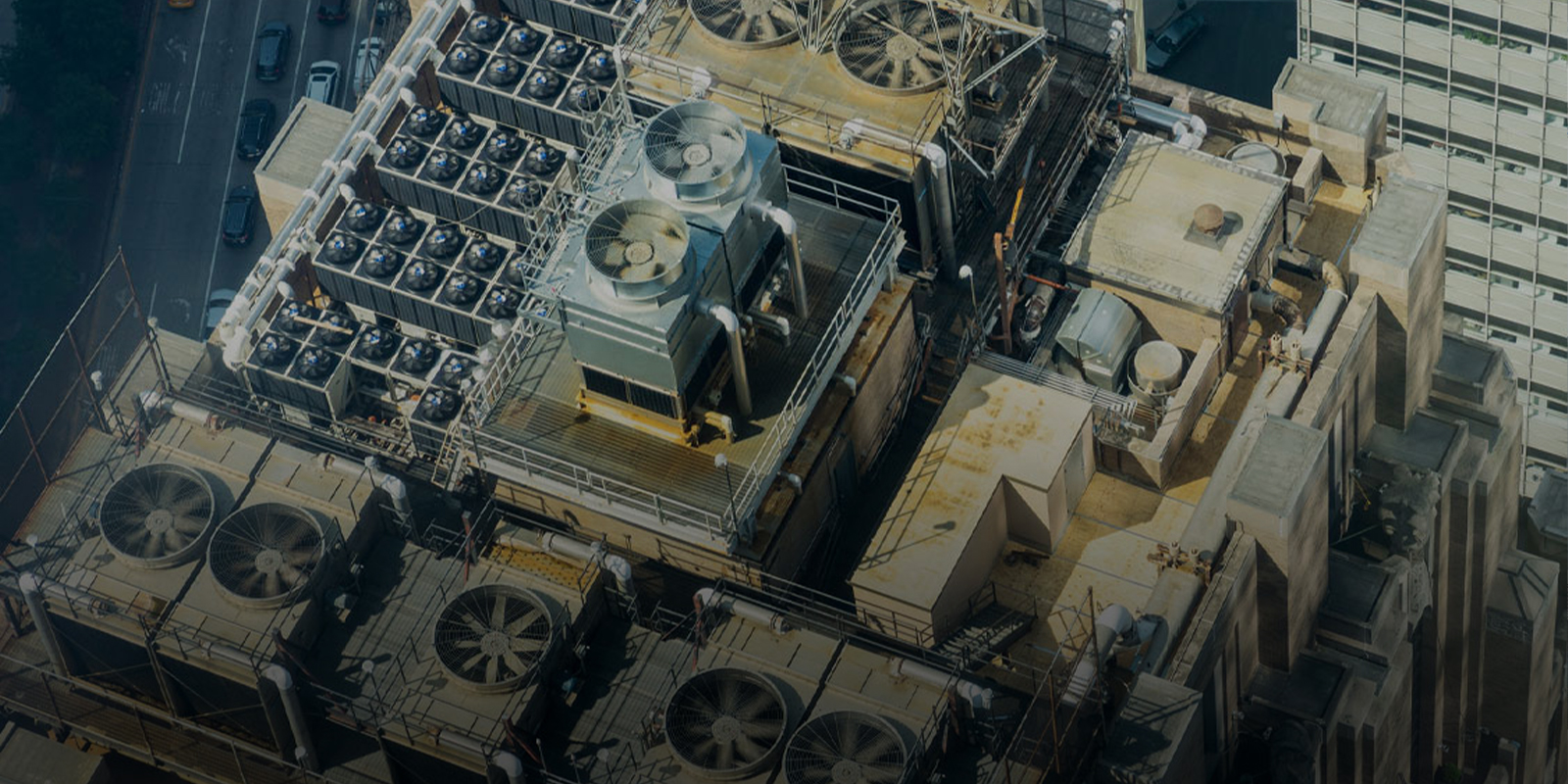

So, how to ensure the stable operation and efficient cooling of wind power equipment in a changeable environment? First of all, we must focus on the nacelle, the "core space".

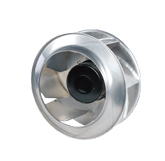

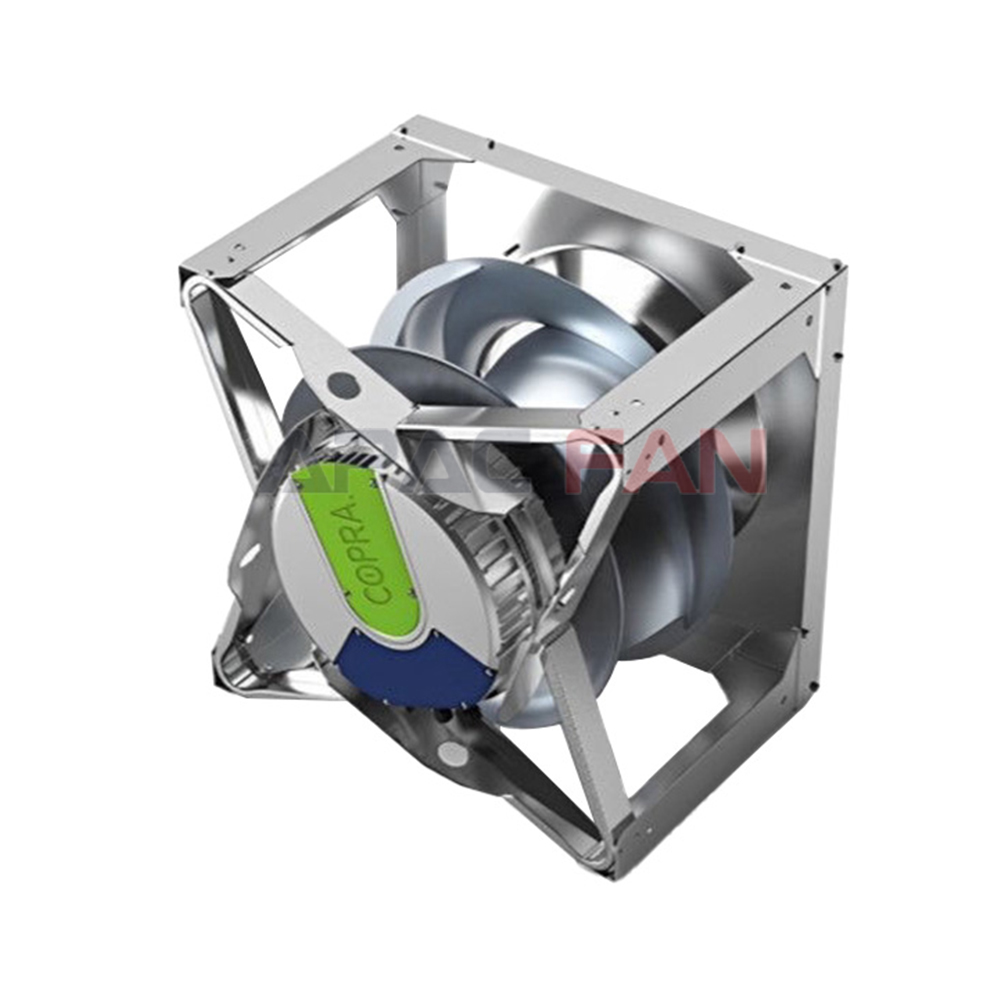

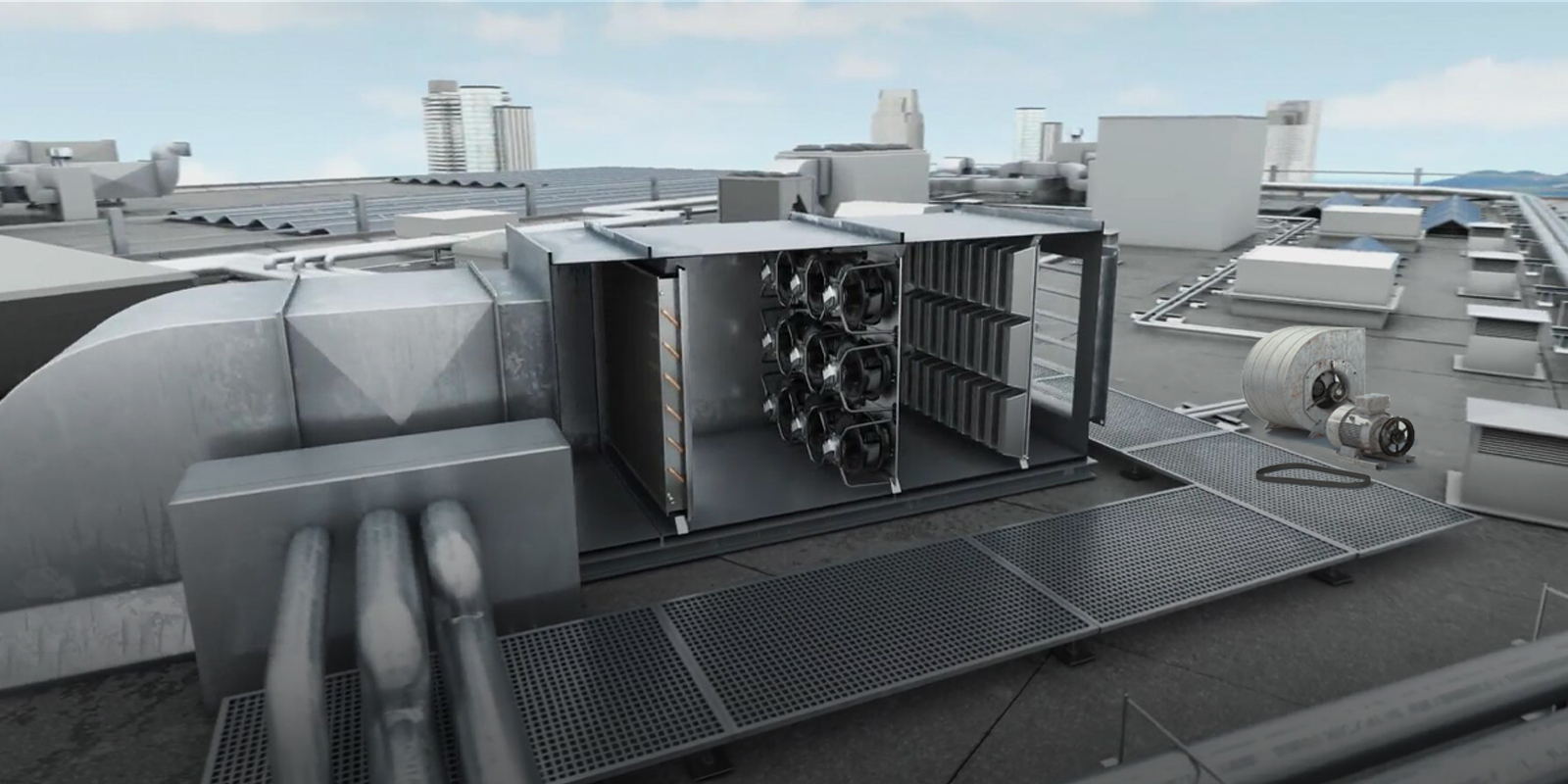

The nacelle is a concentrated area for all key mechanical equipment in a wind farm, and its internal temperature usually needs to be controlled within 30°C. ebm-papst's two major axial fan series - AxiEco and AxiBlade - can meet the performance needs of different application scenarios. Among them, the AxiBlade series has the advantages of high power density and low noise emission; the AxiEco series is especially suitable for application scenarios with limited installation conditions or complex heat exchanger geometric structures, which have high back pressure.

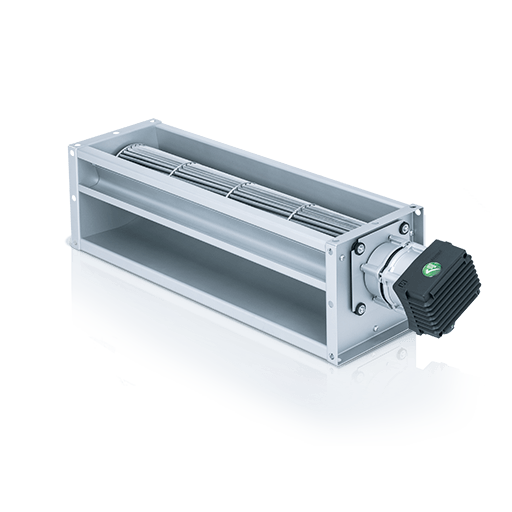

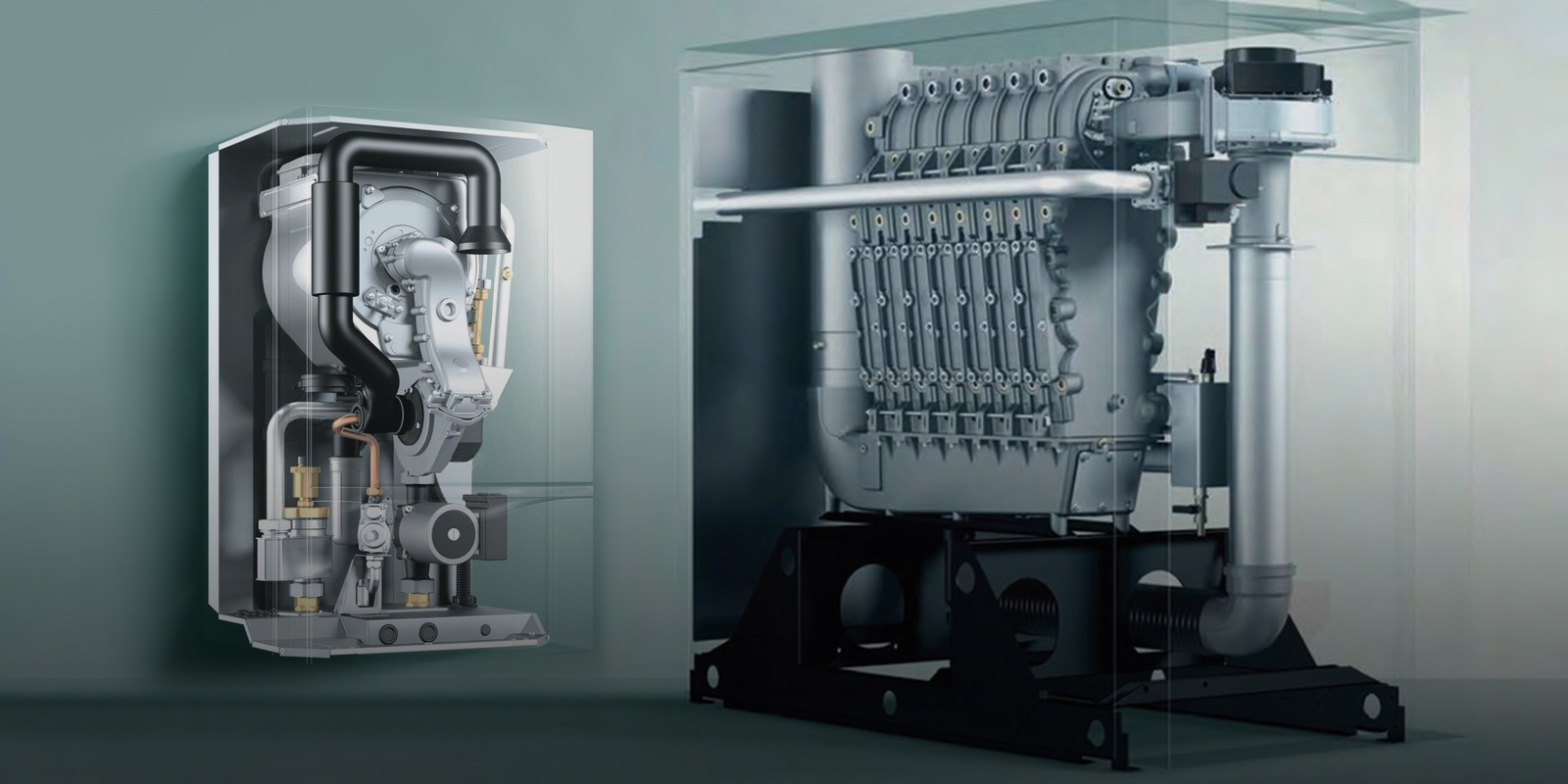

In addition to axial fans, centrifugal fans can also be used for heat dissipation of nacelle air conditioners. Taking the RadiPac centrifugal fan as an example, it optimizes the air outlet characteristics of the impeller through a special design, greatly reducing flow loss. Under the same working conditions, the RadiPac centrifugal fan can operate at a lower speed, thereby significantly reducing energy consumption and reducing operating noise.

If the nacelle is compared to the "torso" of a wind turbine, then the generator is its "heart". As the core equipment of the power generation system, the generator needs to achieve long-term maintenance-free and stable operation as much as possible, and the prerequisite for this goal is that the generator is always within an acceptable temperature range. ebm-papst's RadiPac centrifugal fan has become an ideal choice for generator heat dissipation due to its high power density and durability. It can realize temperature control based on actual needs through Modbus RTU or analog signals. Thanks to the high efficiency of the EC motor, the energy consumed by the fan's own cooling is low, especially in scenarios where multiple fans work together to cool large generators, this energy-saving advantage is more prominent.

Inside the "torso" of the nacelle, the control cabinet and converter play the role of "nerve center", responsible for the transmission and regulation of current. To keep this "nervous system" operating agilely, cooling work is also indispensable.

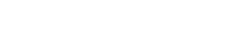

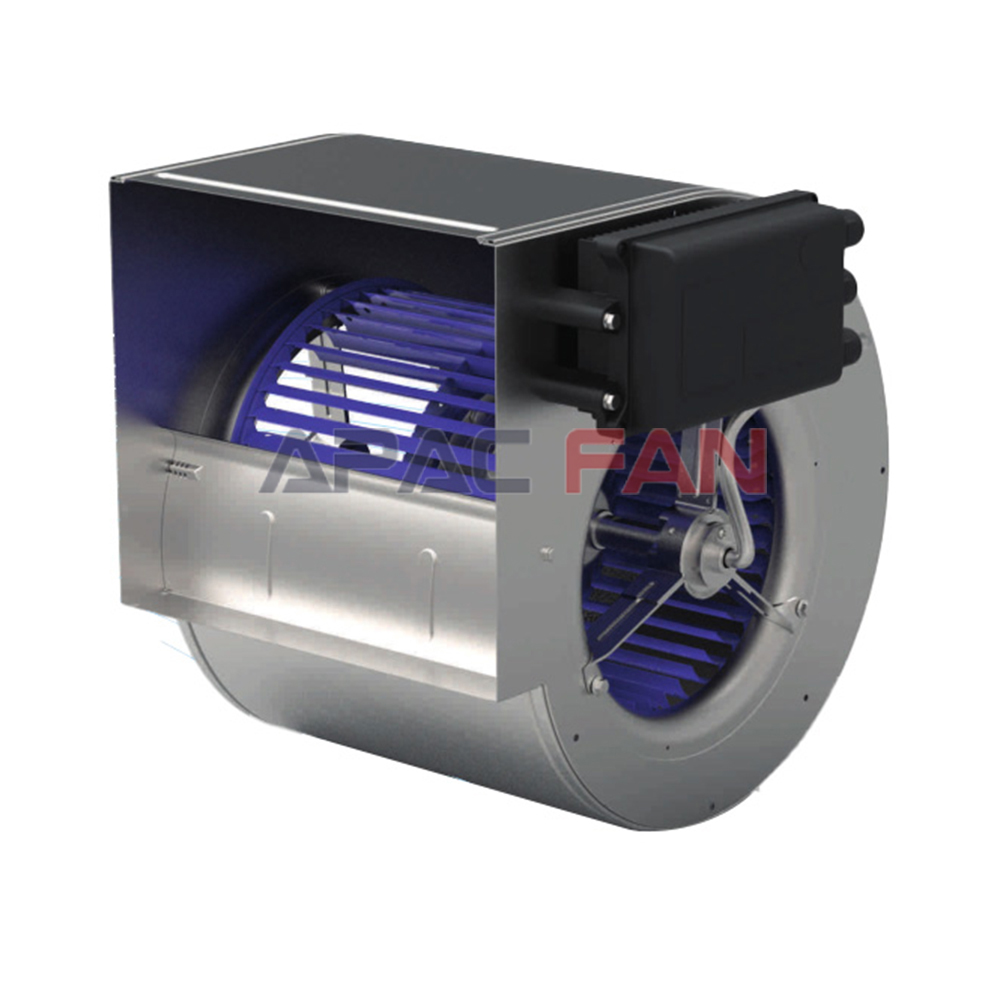

ebm-papst's RadiCal EC fan is suitable for control cabinet cooling, with the characteristics of high air flow, low noise and compact size. The powerful RadiPac EC centrifugal fan is specially used for converter cooling, and its compact structure design can easily adapt to narrow installation spaces. At the same time, the size of the RadiPac product series covers the range of 250 to 1000, with a maximum air pressure of up to 2500 Pa and a maximum air flow of up to 37000 m³/h, which has a wide range of application adaptability.

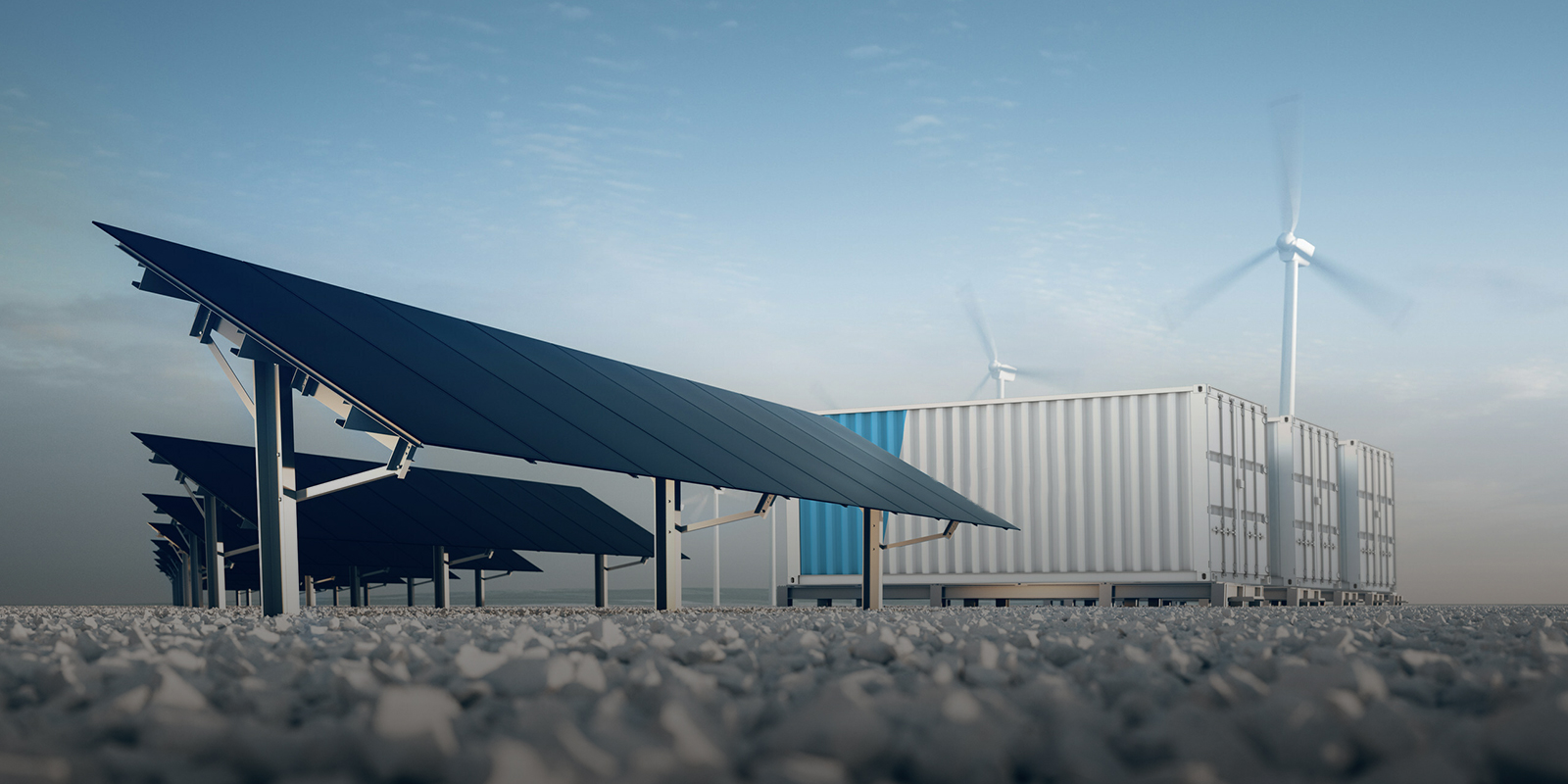

In fact, ebm-papst also provides a variety of fan products suitable for wind farms, and can provide flexible customization services according to the specific needs of customers. Its heat dissipation solutions are not only applicable to the field of wind power generation, but also cover various renewable energy scenarios such as "photovoltaic, energy storage and charging". Relying on the core advantages of "quiet, energy-saving and reliable", it has demonstrated excellent performance in many applications and won wide recognition in the industry.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文