ebm-papst Launches New E-Drive Solution Labs

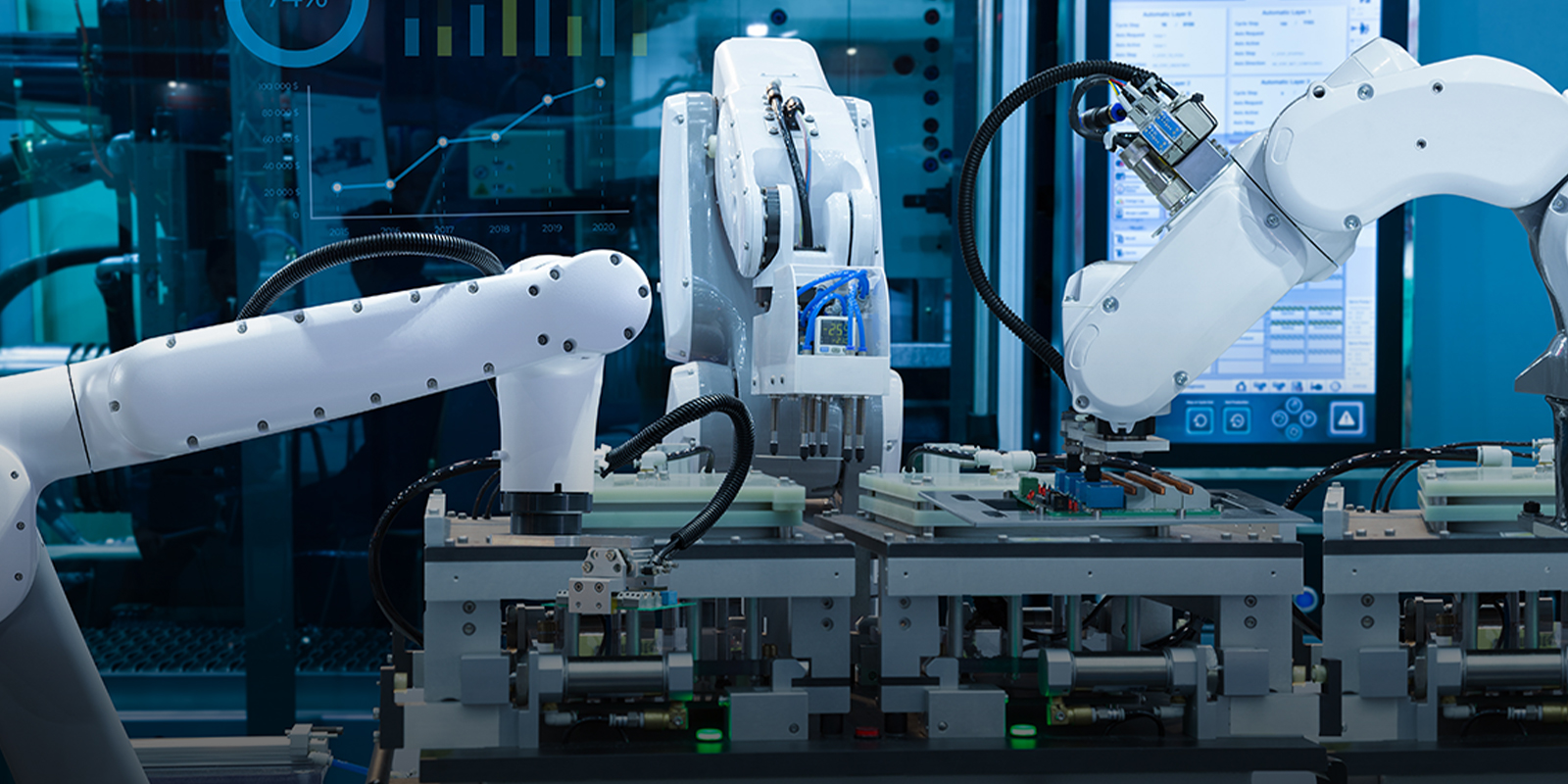

09/11/2025At ebm‑papst’s newly established E-Drive Solution Labs in Mulfingen, roughly 130 engineers, developers, and specialists are collaborating to elevate innovation to new heights. This hub integrates electronics, software, motor technology, and system development, enabling the creation of novel interdisciplinary concepts for the company’s intelligent, tailor-made air technology solutions.

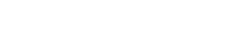

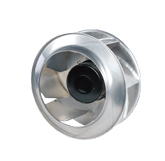

Today, the ebm‑papst Group—globally recognized as a top supplier of fans and motors—officially launched its new E-Drive Solution Labs in Mulfingen. Following the EMC Test Center, the Testing Center, and the HighSpeed Technical Center for turbocompressors, the Solution Labs mark the fourth R&D investment ebm‑papst has made at its headquarters since 2021. This one-of-a-kind industry innovation and development center brings together diverse departments under a single roof, dedicated to crafting solutions for various product lines within the ebm‑papst portfolio.

Manuel Hagel, head of the CDU parliamentary group in the Baden-Württemberg state parliament, delivered a formal welcome address at the inauguration ceremony of the E-Drive Solution Labs. The event also drew attendance from representatives of political, business, and academic sectors, along with approximately 100 other guests.

Dr. Klaus Geißdörfer, CEO of the ebm‑papst Group, stated during the opening: “By working with our team at the Solution Labs, we aim to usher air technology into a new era and further strengthen our technological leadership. In this process, we are also boosting the agility and effectiveness of our motor, electronics, and software development. This is because we are not only uniting all key specialist fields in one center but also prioritizing digitalization, AI, and sustainability—all in line with our ‘Making the Future Together’ strategy. I want to take this chance to thank everyone involved for their relentless efforts in building this space for forward-looking collaboration and innovation.”

Manuel Hagel, speaking at the official launch, commented: “Innovative, efficient, and a global leader—this is what defines Baden-Württemberg’s economy, thanks to strong technology pioneers and role models like ebm‑papst. The future is being built right here in Mulfingen, driven by abundant ingenuity and creativity. At ebm‑papst, hometown roots meet high technology, and passion meets expertise. The company’s success is rooted in its core values and a passion for innovation—and the E-Drive Solution Labs perfectly embody this, as they are where enthusiasm and progress converge.”

Jan Philippiak, a shareholder of ebm‑papst, explained: “We are deliberately investing in Germany and the Hohenlohe region because this area offers valuable expertise—from quality education and universities—to motivated, dedicated employees. Additionally, the Solution Labs are highly appealing to specialists, managers, and engineers.”

Innovative Solutions Pave the Way for Future Trends

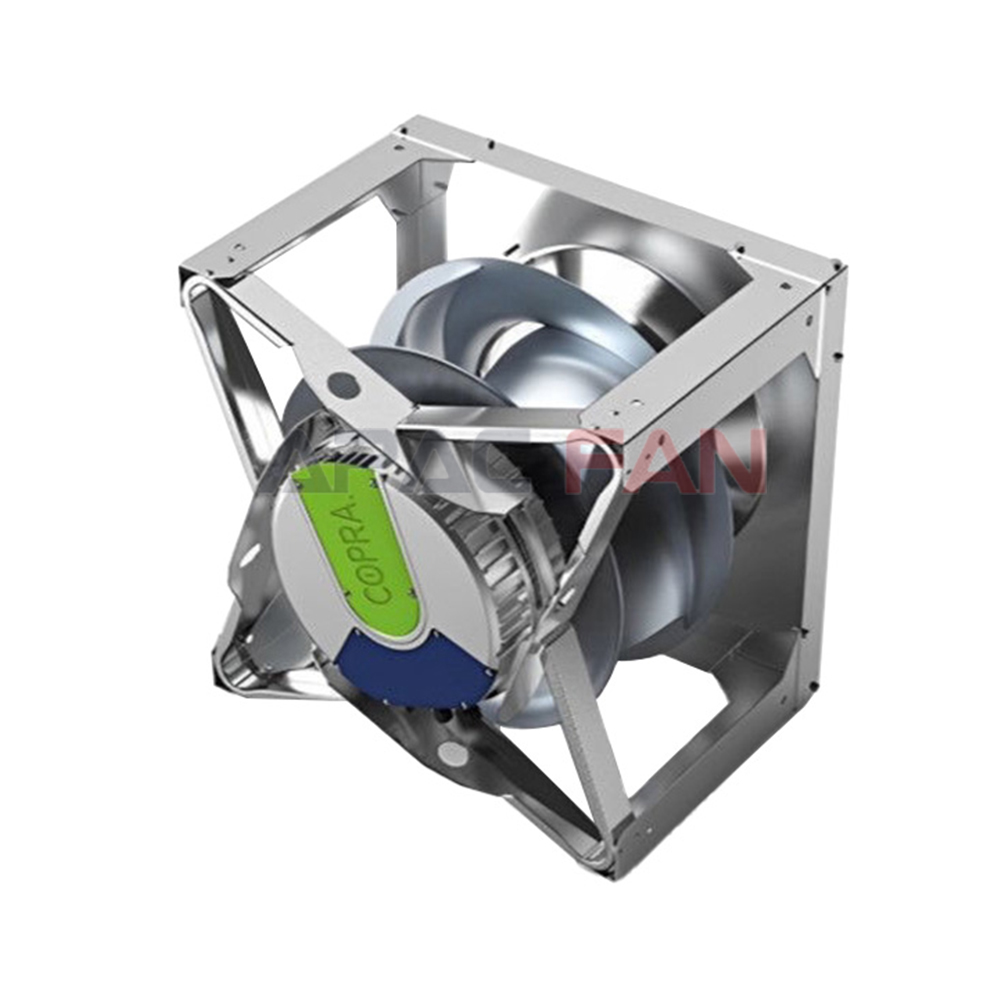

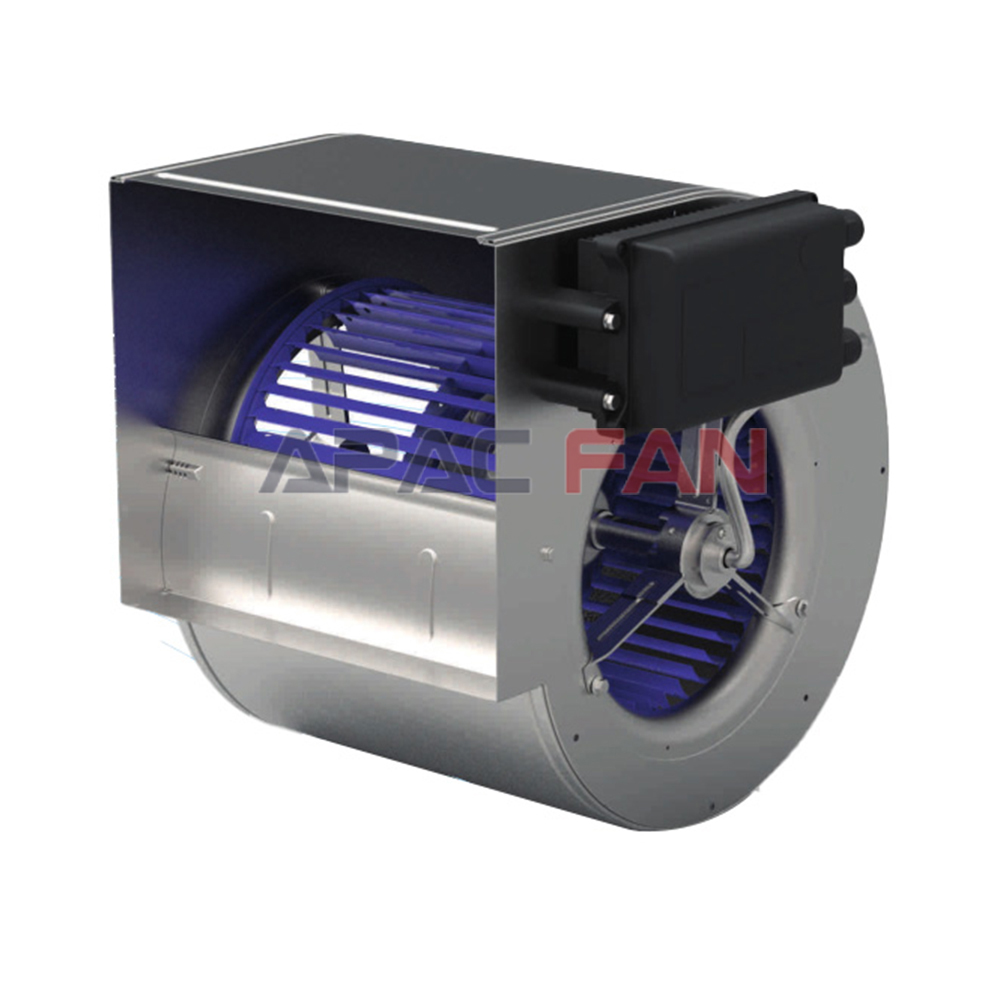

ebm‑papst has invested approximately 30 million euros in the new Solution Labs, which took two years to complete. The facility consolidates a range of capabilities from the E-Drive Solutions division under one roof, including electronics, motors, embedded computing, application and series development, and innovation and knowledge management.

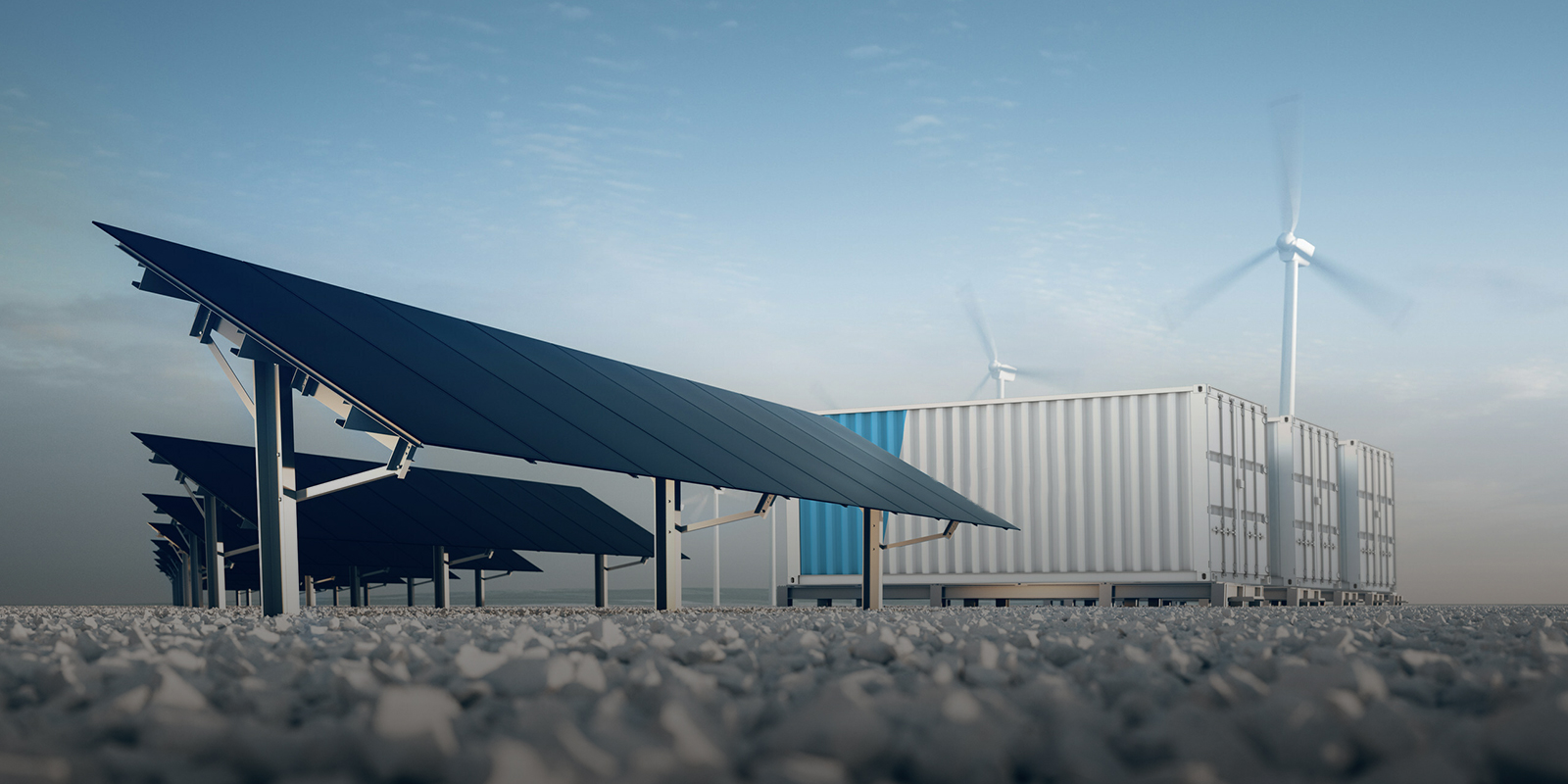

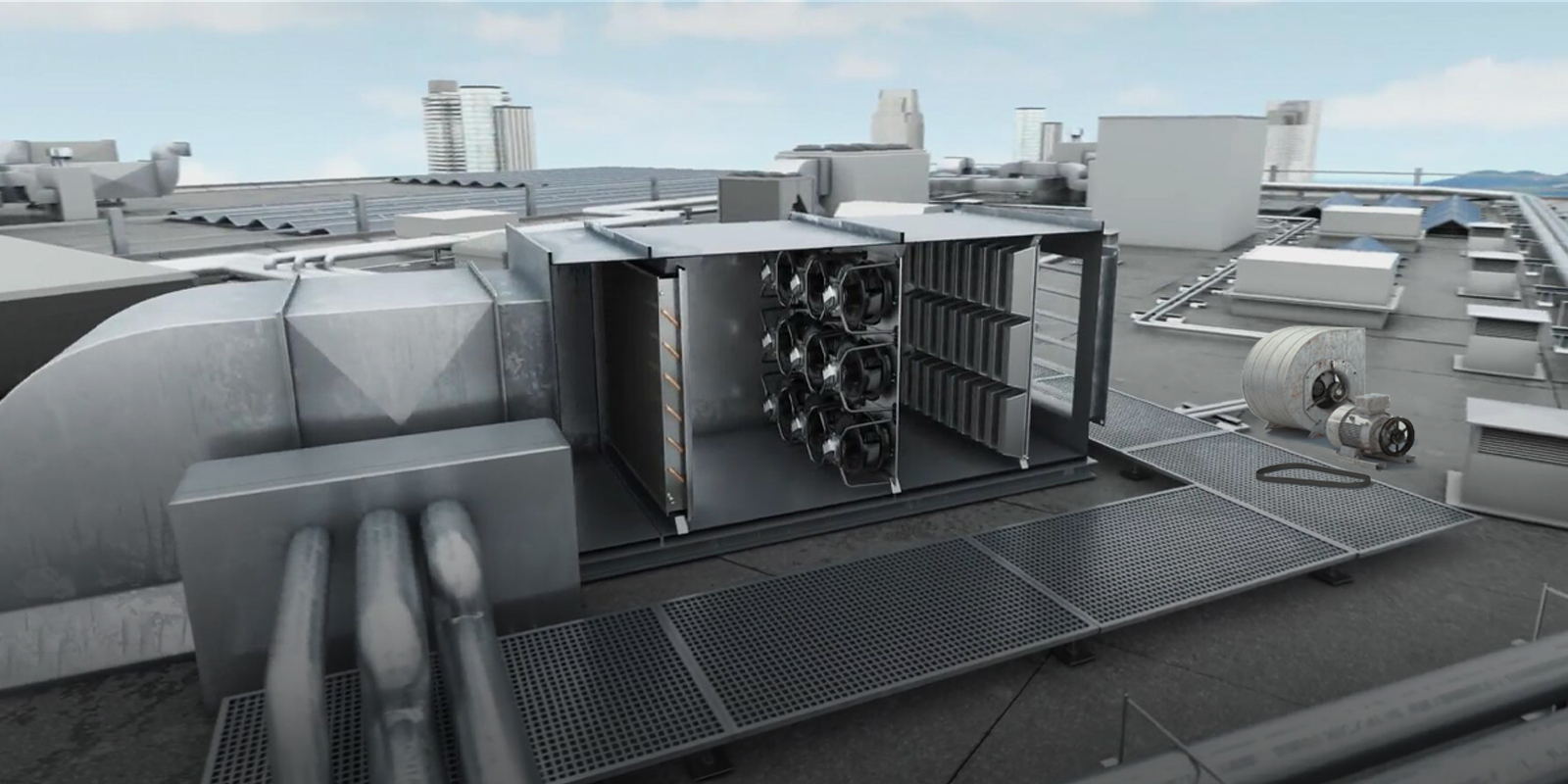

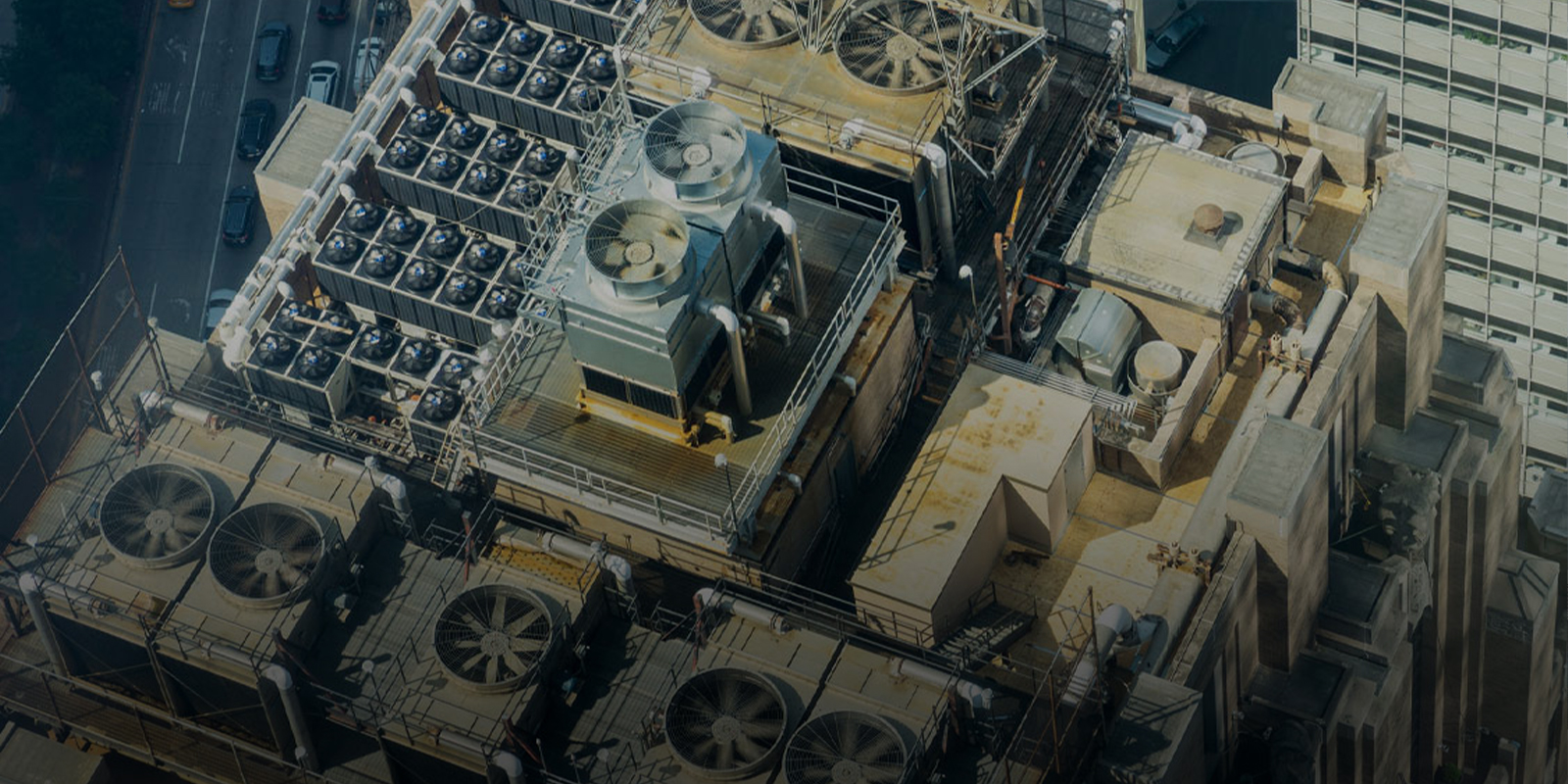

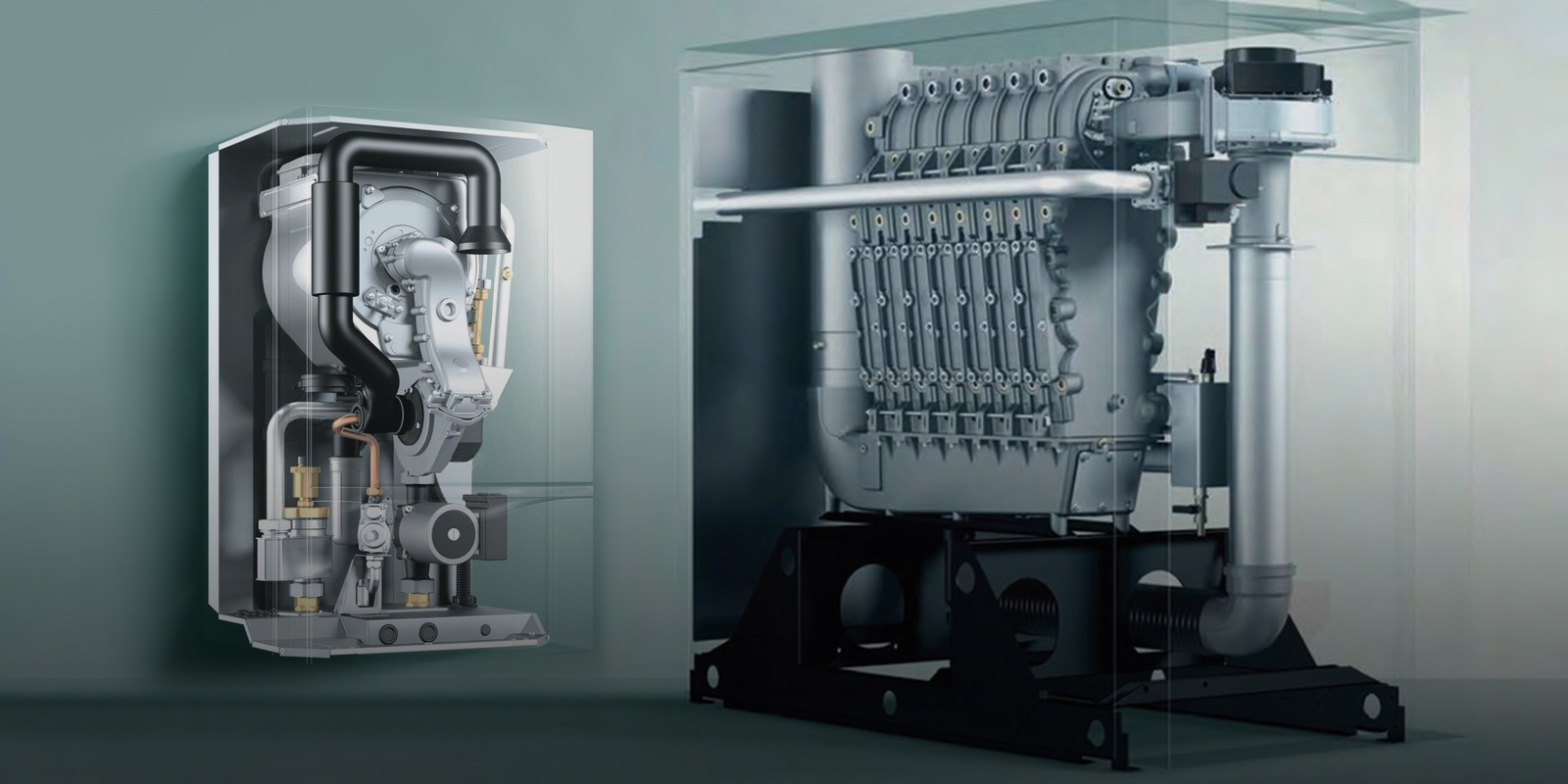

Professor Tomas Smetana, Chief Technology Officer, noted: “The roughly 130 employees at the Solution Labs work closely with all relevant product development departments—spanning from innovation development to series development. Our goal is to develop new, cutting-edge solutions in areas that will shape the future, such as digitalization, data centers, and the heat transition.” The labs also maintain close collaborative ties with ebm‑papst’s existing EMC Test Center and HighSpeed Technical Center in Mulfingen.

Solutions developed at the Solution Labs for pre-series and series products—covering everything from individual components to customers’ final devices—undergo testing, optimization, and verification at the EMC Laboratory. For instance, the electronics used in compressors developed at the HighSpeed Technical Center are sourced from the Solution Labs. Furthermore, the concepts and ideas from the labs are integrated into ebm‑papst’s modular motor system, which is then adapted by the company’s various divisions and regional teams to meet local market needs and requirements.

A unique feature of the Solution Labs is its building architecture: it is constructed atop an existing production facility, a design choice that saves space and supports sustainability. Across the facility’s approximately 3,200 square meters, ebm‑papst has prioritized minimizing distances between departments and laboratories.

The labs also feature an open-space layout, which encourages communication and creative knowledge sharing among employees. Complementing this, an energy-efficient heating and cooling system—connected to the new district heating and cooling network—and a well-designed lighting system ensure the facility meets high standards of sustainability and employee comfort.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文