Powered by ebm-papst motors! DFI and CityFM collaborate to revitalize supermarket refrigeration equipment

09/05/2025DFI Retail Group is one of Asia's largest retailers, operating 10,600 supermarkets and grocery stores across 13 countries and regions under 27 brands. As the group's facilities management team, DFI is responsible for ensuring the smooth operation of these stores. Market Place, located within The Wai shopping mall in Hong Kong, is just one of tens of thousands of supermarkets managed by DFI, which also includes Wellcome supermarkets and 7-Eleven convenience stores, meeting the daily needs of millions of people in the Pearl River Delta metropolitan area. Three years ago, DFI set out its own climate plan: "We aspire to reduce carbon emissions by 50% by 2030 and achieve climate neutrality by 2050," DFI stated.

To accomplish this mission, DFI turned to City Facilities Management (HKG) Ltd. (CityFM), one of the world's largest facilities management companies. CityFM offers clients a wide range of facilities management services, including routine equipment maintenance, cleaning services, and smart energy-saving strategies. Together, the two companies are taking steps to reduce DFI's carbon footprint.

DFI Retail Group operates 10,600 supermarkets across Asia and aims to achieve carbon neutrality by 2050. This presents a daunting task for DFI's facilities management.

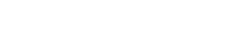

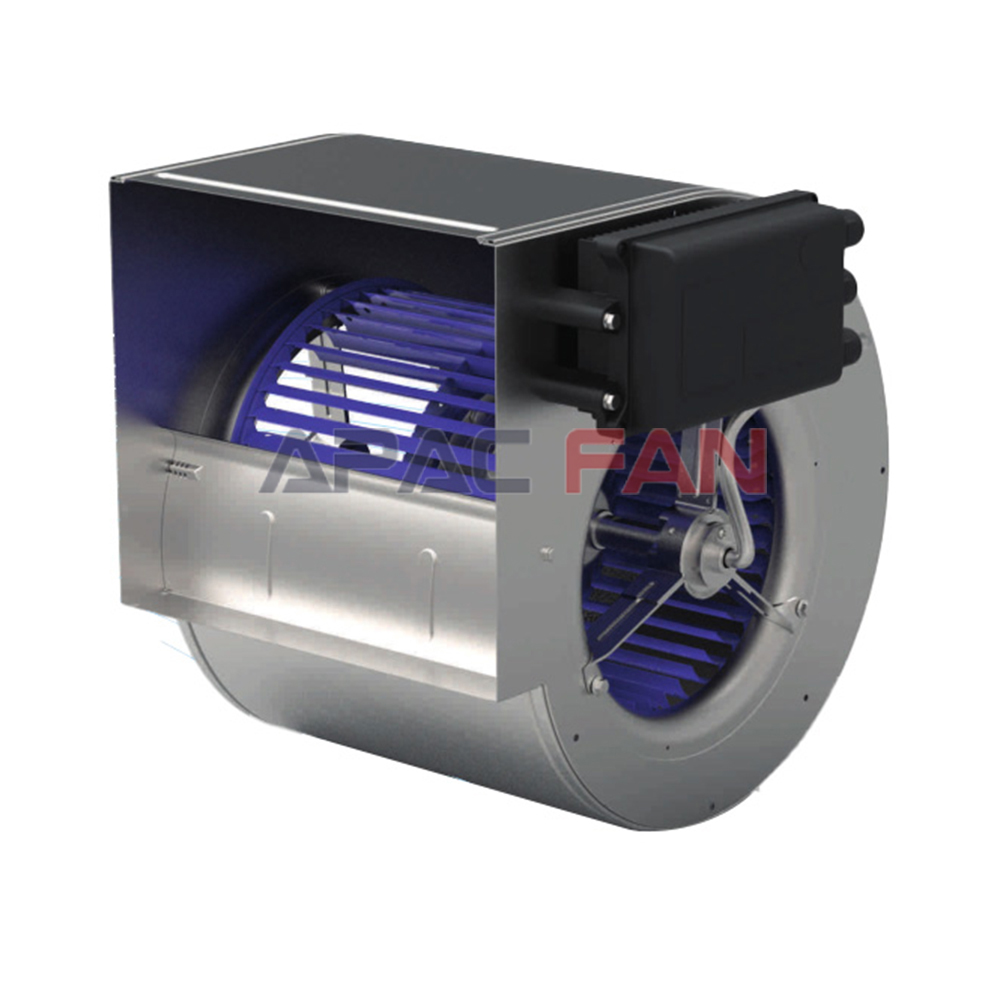

Supermarkets are energy-intensive, with refrigeration and air conditioning accounting for a significant portion of electricity consumption. DFI explains, "It's extremely hot and humid most of the time. We battle these conditions daily to maintain a constant temperature of 0-4°C in our refrigerated display cases and -18°C in our freezers." Therefore, refrigerated and display cases are crucial for reducing energy consumption. CityFM explains, "Most of the equipment uses AC motors, so we decided to replace them with efficient EC technology." To this end, CityFM contacted the ebm-papst team in Hong Kong.

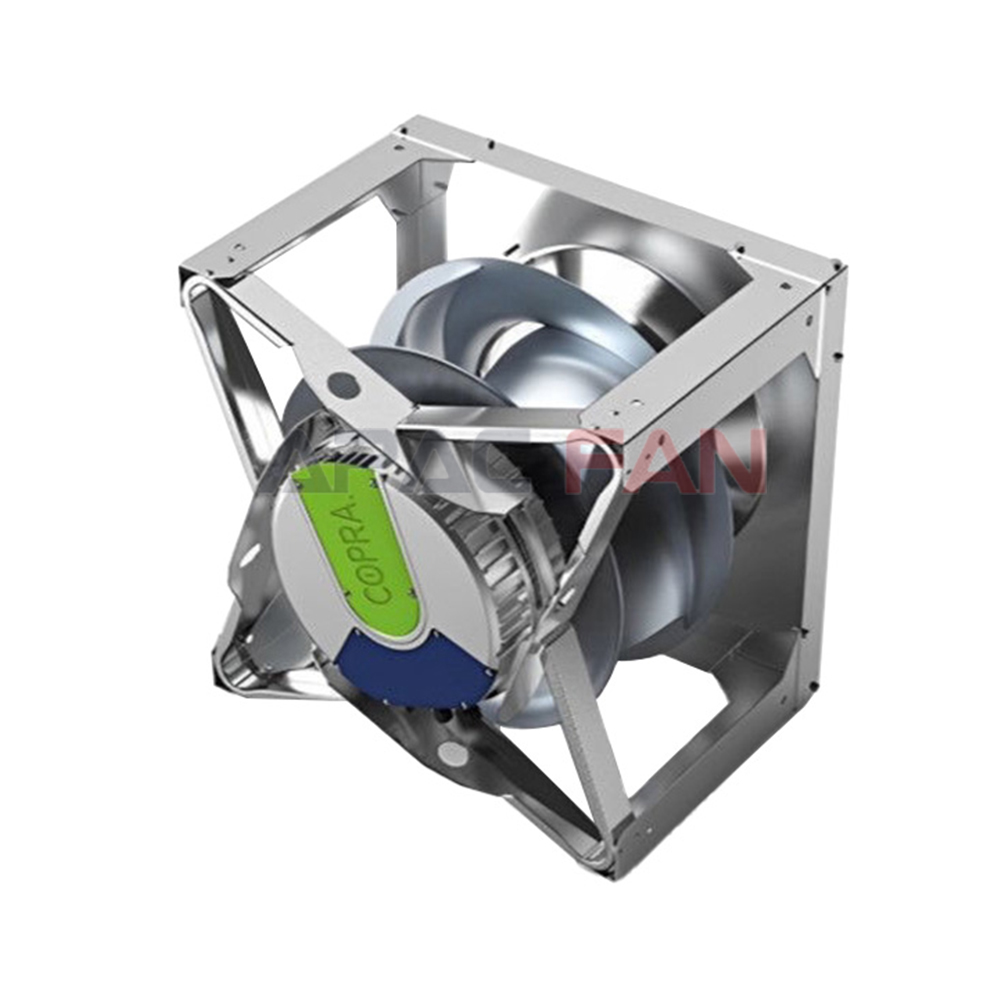

High-Efficiency Motors for Refrigeration

In Hong Kong, CityFM met with the ebm-papst Hong Kong team, which is familiar with solutions for refrigerated and display cases. The ebm-papst Hong Kong team explained, "Our iQC motors are specifically designed for refrigeration equipment and are well-suited to harsh environments." Motors are crucial to the efficient operation of these equipment. They run around the clock, driving fans that evenly distribute cold air throughout the equipment. Failures put the risk of product spoilage, so high reliability is essential. Thanks to EC technology, iQC motors offer significantly higher efficiency than older models in the iQ motor series, while maintaining the same size. The ebm-papst Hong Kong team further explained, "This makes them ideal for retrofits."

For DFI and CityFM, this marks a milestone—80% of their equipment has now been replaced with ebm-papst motors. Initially, DFI and CityFM selected only three supermarkets for a pilot project, replacing their older motors with new iQC motors. DFI and CityFM were impressed by initial measurements, which showed a 75% reduction in fan power consumption while also improving air quality. CityFM stated, "We also consulted with other manufacturers, but none of their solutions performed as robustly as iQC."

Record-Breaking Retrofit Time

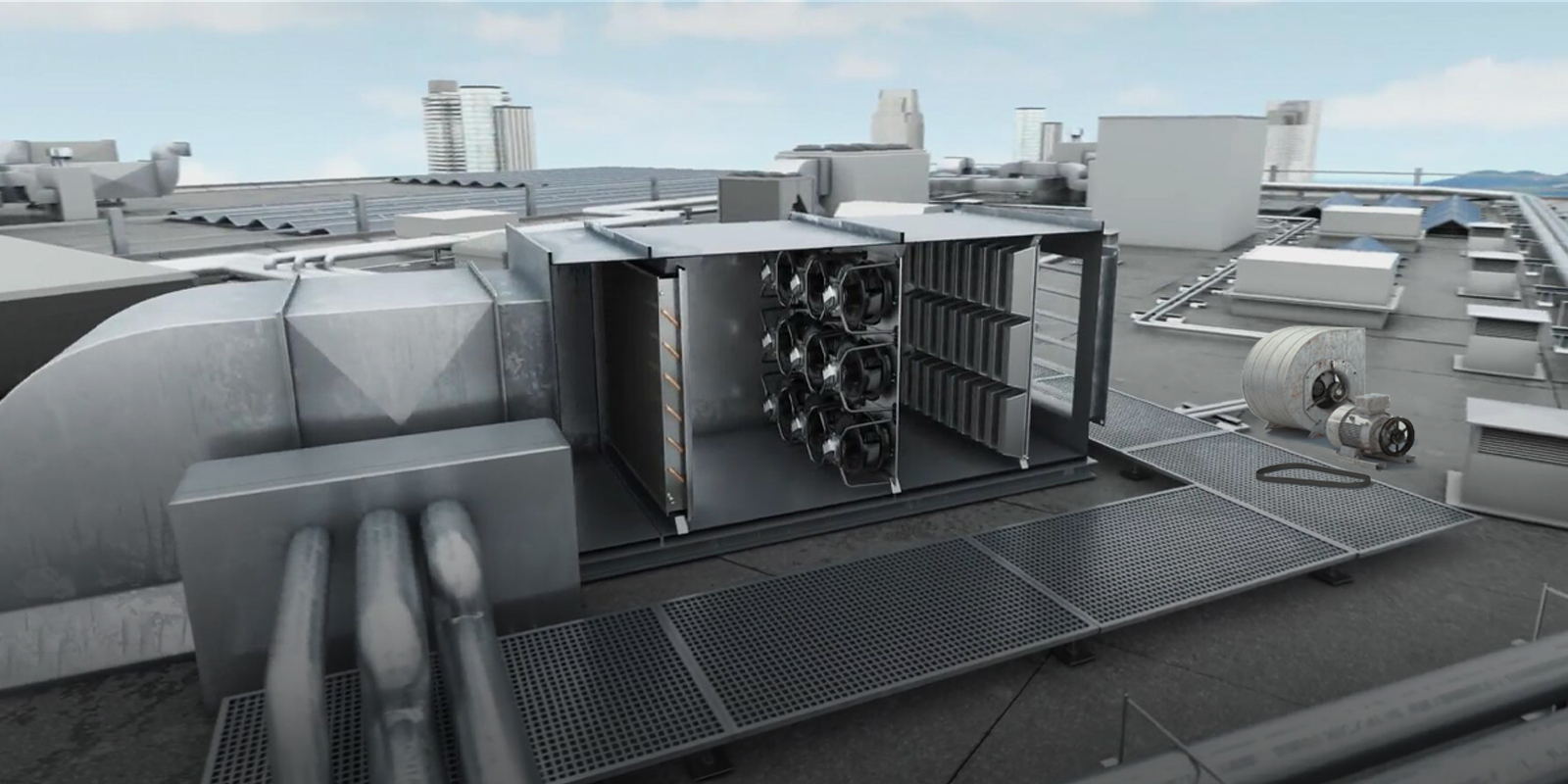

Based on the success of the pilot project, DFI and CityFM decided to implement the retrofit on a large scale, aiming to replace approximately 10,000 motors across approximately 1,000 stores in Hong Kong in just six months. This was no easy task, not only due to the large number of personnel involved and the intense time pressure. DFI noted, "For a project of this magnitude, we had to coordinate a large number of people in advance." Furthermore, the need to minimize disruption to store operations and ensure normal business operations remained. For the staff, this meant numerous night shifts, as the retrofits had to be performed outside business hours—as soon as the last customer left, the assemblers would begin moving merchandise, replacing the motors, and returning everything to the units. The retrofit took approximately one hour per refrigeration unit. CityFM explained, "The process was straightforward; the old motors were swapped out for the new ones in under 10 minutes."

Excellent Energy Footprint

The effort paid off, with DFI reducing carbon emissions by 1,270 tons in just six months. This is not only good for the climate but also good for business—the measure has already saved DFI $350,000. DFI states, "The retrofit will pay for itself within two years." Furthermore, thanks to EC technology, the iQC motors have a longer lifespan. The retrofit brings DFI one step closer to its climate goals, and further retrofits are planned for its branches in Singapore and Malaysia.

For DFI and CityFM, the equipment upgrade not only helps reduce operating costs in the long term, but also demonstrates to other industry players their commitment to energy conservation, emissions reduction, and sustainable development. ebm-papst is committed to helping customers reduce carbon emissions through sustainable and intelligent solutions, working with them to create a better future.

Resource: https://mp.weixin.qq.com/s/D8T0vMz1wyqDnGDgA0BMEQ

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文