How to Select ebm-papst Fans for CRAC & CRAH Units

01/26/2026The selection of cooling fans is a foundational engineering decision in the design and operation of data center environmental control systems. Within Computer Room Air Conditioner (CRAC) and Computer Room Air Handler (CRAH) units, fans are the primary actuators responsible for moving air across heat exchange surfaces and distributing conditioned air throughout the white space. The choice of fan directly dictates the system's energy efficiency, airflow stability, acoustic signature, and overall reliability. As data centers evolve towards higher densities and more dynamic workloads, the traditional approach of using fixed-speed AC fans is increasingly inadequate. Modern facilities demand intelligent, variable-flow solutions that can adapt in real-time to thermal loads while minimizing power consumption. This makes the selection of advanced fan technology, particularly Electronically Commutated (EC) fans from manufacturers like ebm-papst, a critical strategic consideration. The process moves beyond simply matching a catalog specification to a required airflow; it involves a holistic analysis of system interaction, control philosophy, redundancy architecture, and total cost of ownership.

Understanding System Requirements and Performance Parameters

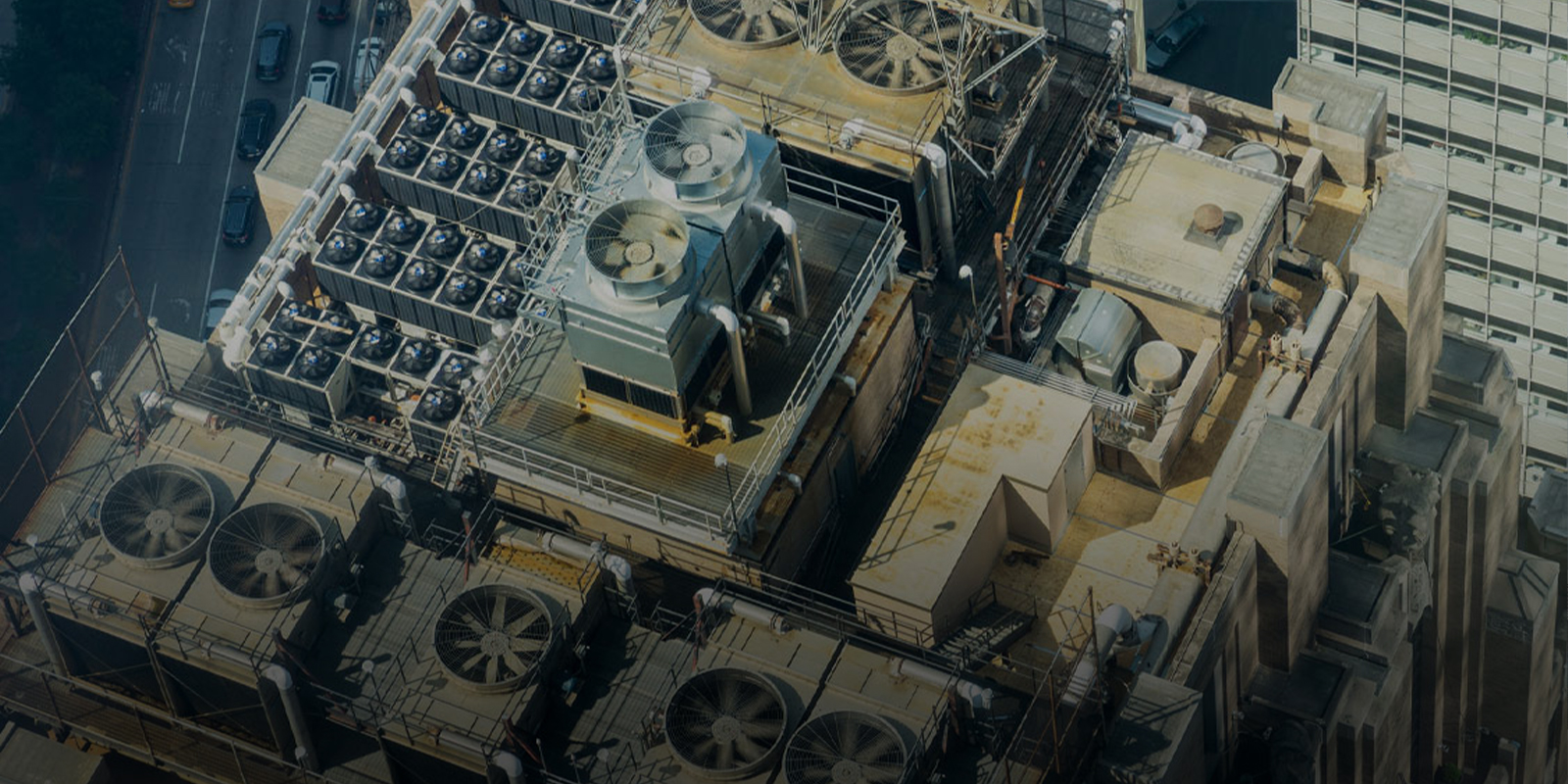

The first step in fan selection requires a clear distinction between CRAC and CRAH unit applications, as their core mechanics influence fan performance needs. CRAC units, which typically employ a direct expansion (DX) refrigeration cycle, are often self-contained. Their fans must overcome the pressure drop of an internal evaporator coil, air filters, and any internal dampers or partitions. CRAH units, in contrast, use chilled water coils and are the standard in large-scale and hyperscale facilities. While they lack a compressor, their fans must handle the pressure drop of a water coil, which can be significant, along with filters and ductwork. In both cases, the fan is working against a "system curve" – a relationship between the airflow it produces and the static pressure it must overcome. Accurately defining this curve is paramount. Underestimating the total external static pressure (ESP)—which sums coil resistance, filter pressure drop (both clean and, critically, loaded), duct losses, and grill resistance—will result in an underperforming fan that cannot deliver the designed airflow. Conversely, grossly oversizing the fan leads to inefficient operation, excessive energy use, potential aerodynamic instability, and higher noise levels. ebm-papst fans, renowned for their stable performance curves even at higher pressures, are engineered to maintain consistent airflow as system resistance changes over time, such as when air filters become loaded with particulate.

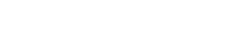

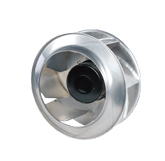

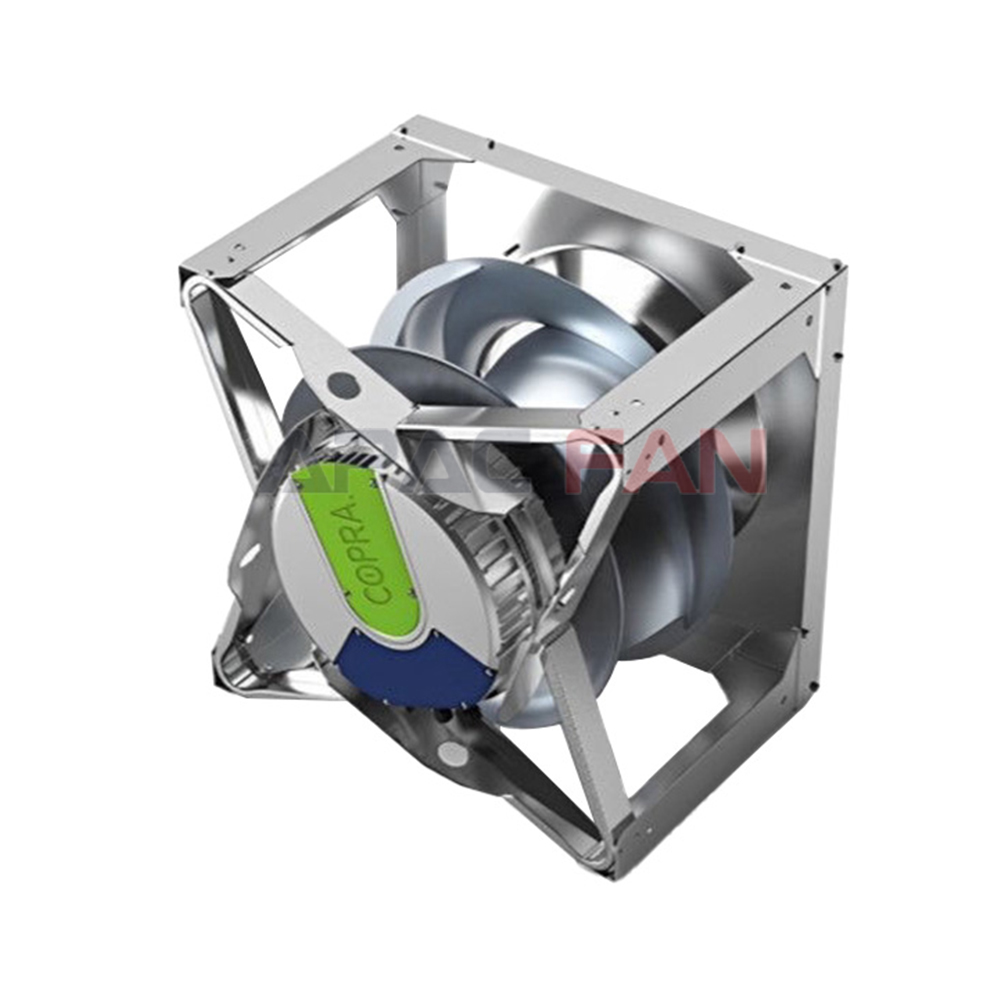

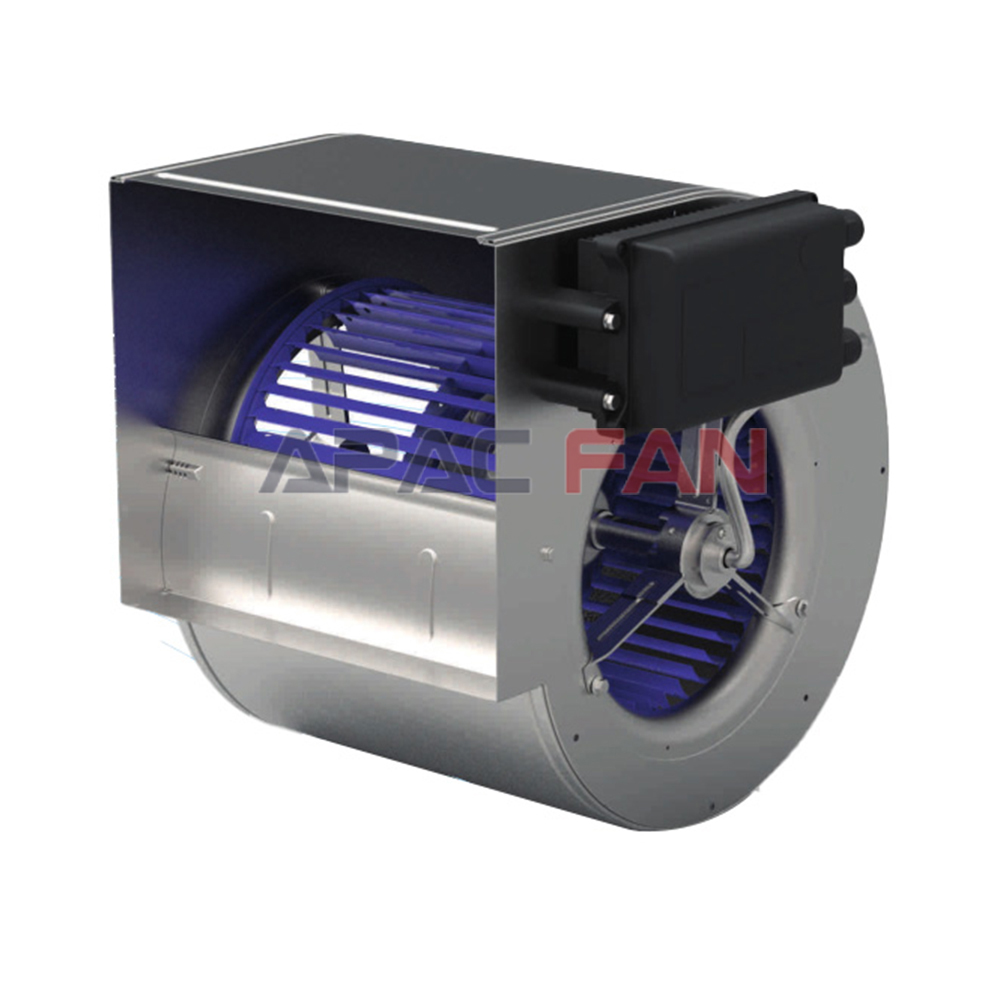

Choosing the Optimal Fan Technology and Type

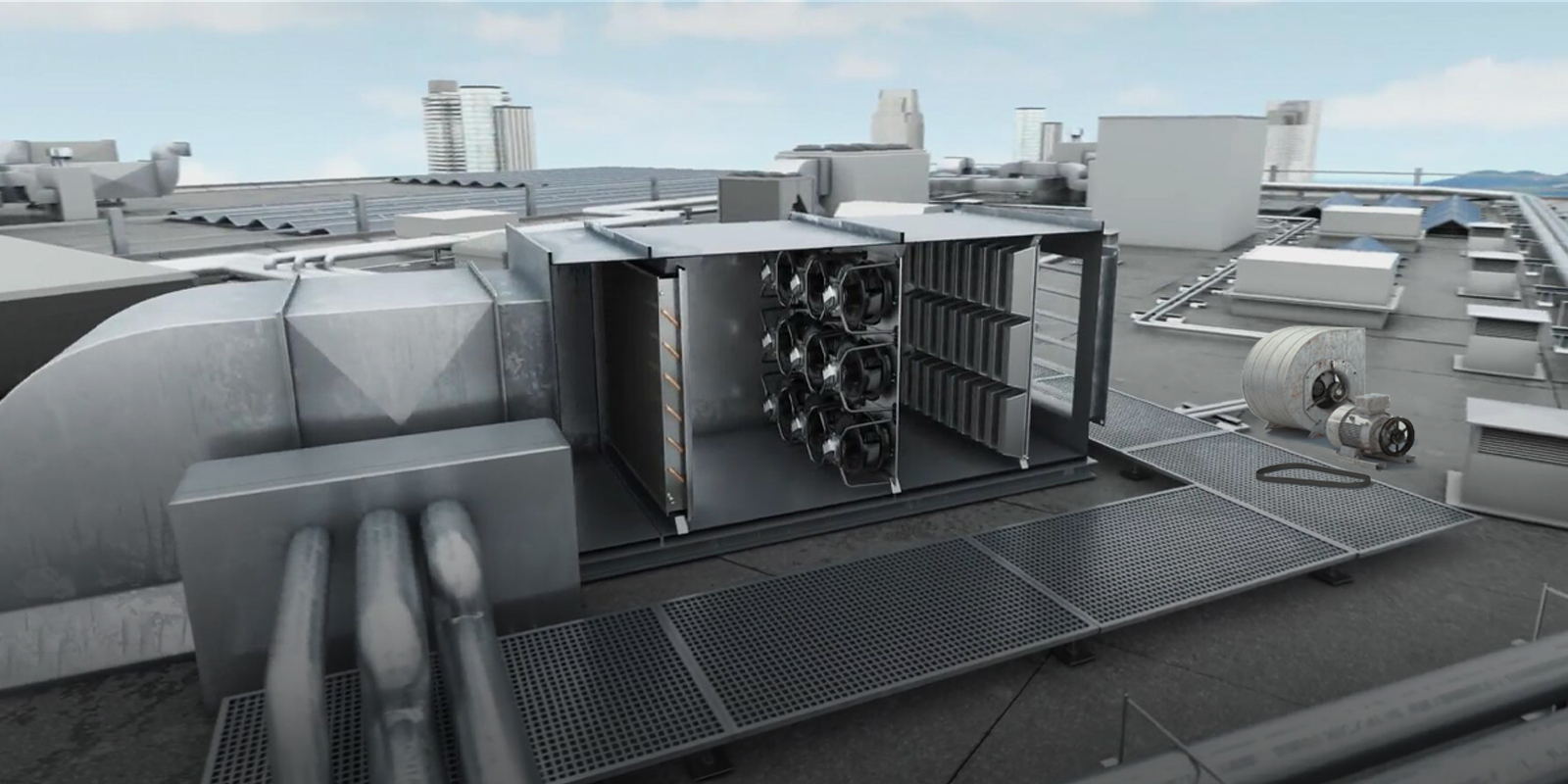

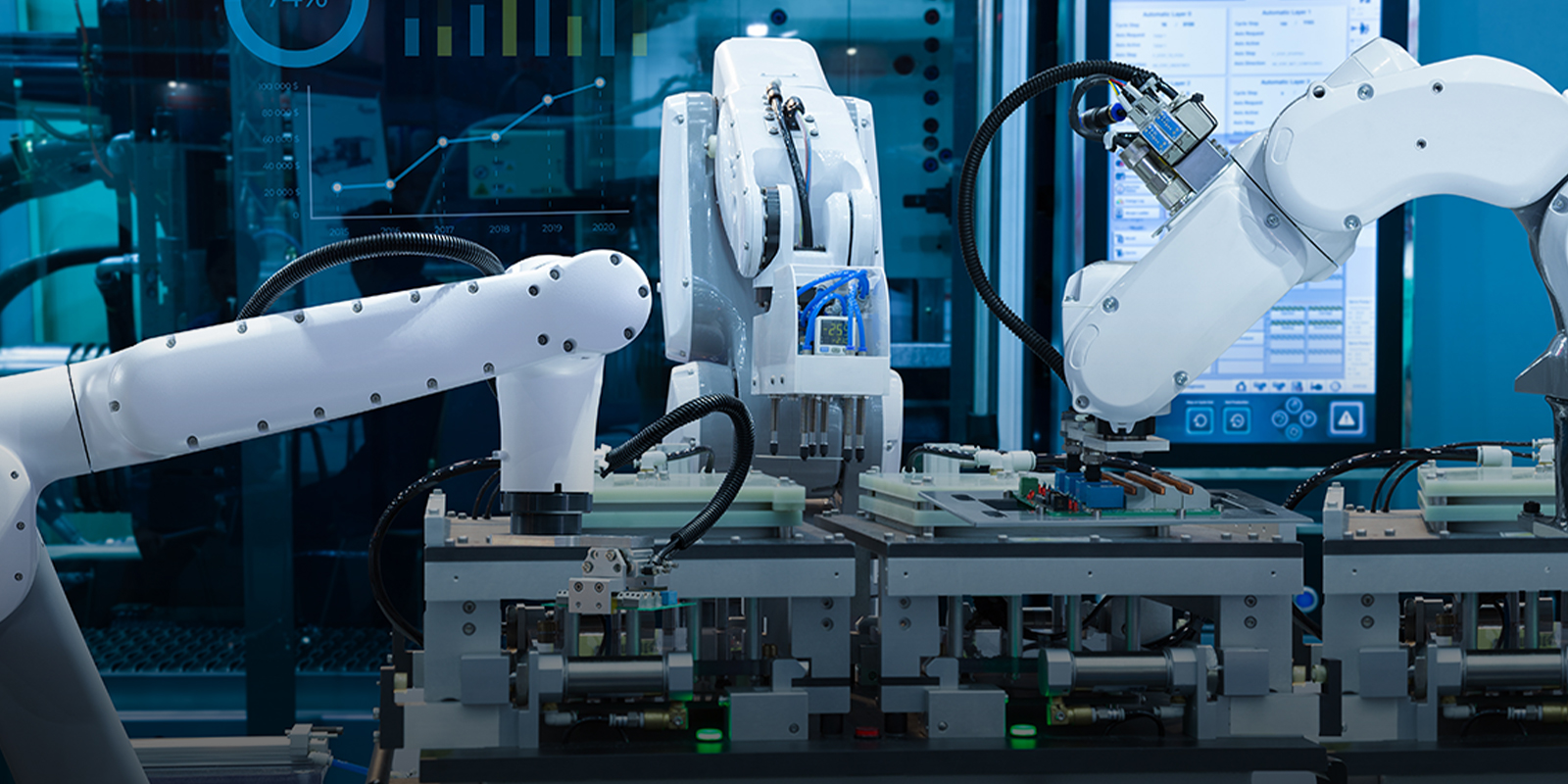

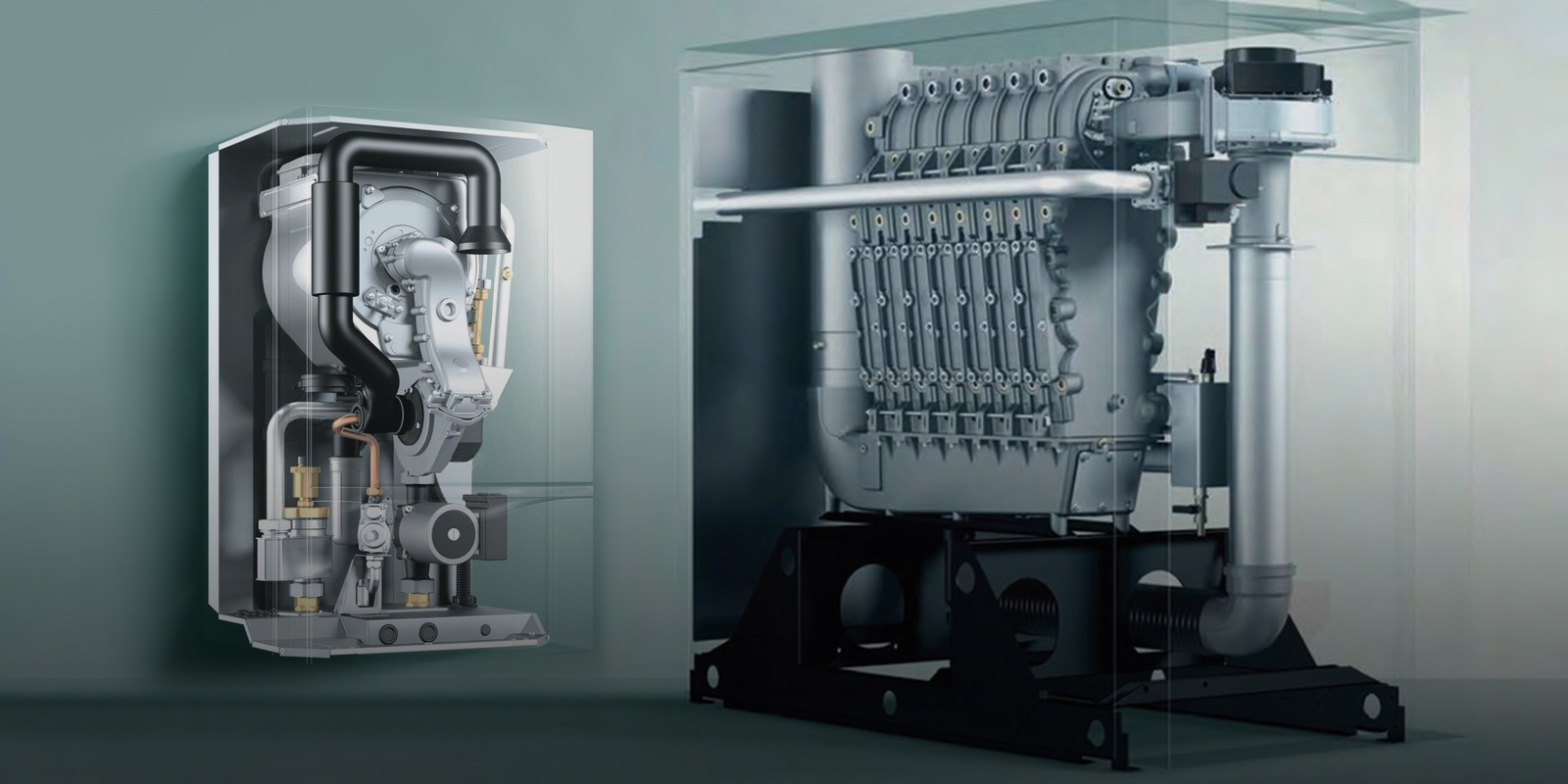

With system requirements defined, the focus shifts to selecting the appropriate fan type and motor technology. For CRAC and CRAH applications, AC induction motors are largely being superseded by EC technology due to its profound efficiency benefits, especially at partial loads. An EC fan incorporates a permanent magnet motor with integrated speed control electronics. This allows for near-perfect power factor and dramatic energy savings across a wide speed range, as the fan only uses the power necessary to meet the instantaneous cooling demand. ebm-papst offers several EC fan families, each optimized for different applications within cooling units. For traditional, ducted CRAC units with space constraints and high-pressure needs, centrifugal fans with backward-curved impellers are the industry staple. Their non-overloading power characteristic and ability to generate high pressure make them ideal. For modern CRAH units, particularly those employing a "fan wall" design for modularity and redundancy, EC plug fans are often the preferred solution. These fans, installed in a matrix, offer easy individual replacement, excellent efficiency, and inherent support for N+1 redundancy schemes. In hybrid units that incorporate free cooling via an air-to-air heat exchanger or adiabatic section, EC axial fans provide a high-airflow, low-pressure solution for that specific airflow path. The choice between these types hinges on the pressure/flow duty point, physical configuration of the unit, and maintenance philosophy.

Integration, Control, and Operational Excellence

The true value of a modern EC fan is realized through its integration into the unit's and the data center's broader control ecosystem. ebm-papst fans are not just components; they are intelligent nodes. They accept standard control signals such as 0-10V DC analog or PWM, and provide valuable feedback signals like actual speed (tacho output) and alarm status. This two-way communication is essential for sophisticated control strategies. The Building Management System (BMS) or Data Center Infrastructure Management (DCIM) software can modulate fan speed based on return air temperature, rack inlet temperatures, or differential pressure, creating a demand-based cooling response. This granular control is a primary lever for improving the facility's Power Usage Effectiveness (PUE). Furthermore, the ability to receive an alarm signal from a fan allows for predictive maintenance, alerting operators to an impending failure before it causes a temperature excursion. This capability is crucial for implementing robust redundancy. In an N+1 fan wall, if one fan fails, the control system can ramp up the remaining fans to compensate, and the alarm signal ensures a technician is dispatched to replace the faulty unit promptly, restoring the redundancy buffer. ebm-papst fans are specifically designed and tested for 24/7 operation at elevated ambient temperatures, ensuring this reliability over a long service life.

Addressing Secondary Considerations and Avoiding Pitfalls

While performance and efficiency are primary, other factors influence the final selection. Noise emissions, though secondary to mission-critical cooling, are important in edge data centers located in office environments or colocation facilities with strict lease agreements. ebm-papst invests heavily in aerodynamic design, using advanced impeller geometries and housing designs to minimize turbulence and broadband noise. Their smooth EC motor control also eliminates the magnetic "hum" associated with AC motors, resulting in a more acoustically palatable profile. From a project execution standpoint, global data center developers require components that meet international safety and efficiency standards (like IEC, UL, CE) and are available through a stable, long-term supply chain. ebm-papst's global manufacturing and support footprint provides this assurance. Common selection errors to avoid include specifying fans based on free-air delivery (zero pressure) performance, ignoring the control interface requirements until too late in the design, and selecting a fan that operates near the instability region of its curve, which can cause surge and vibration. A thorough selection process, often supported by expert application engineering, mitigates these risks.

In conclusion, specifying fans for CRAC and CRAH units is a multi-dimensional engineering task that balances immediate performance with long-term operational efficiency and resilience. By leveraging ebm-papst's range of EC centrifugal, plug, and axial fans, system designers gain access to technology that is inherently efficient, precisely controllable, and designed for relentless reliability. This choice directly translates into lower operational expenses through reduced energy consumption, enhanced cooling system stability that protects IT equipment, and the intelligence needed to integrate with modern data center management platforms. In an industry where cooling can constitute a significant portion of the total energy bill, and where uptime is paramount, the selection of the right fan partner is an investment in the data center's performance, sustainability, and bottom line.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文