ebm-papst Fans Empower Semiconductor Industry

12/12/2025With the explosive growth of emerging technologies such as artificial intelligence, the Internet of Things, 5G communications, and electric vehicles, the global semiconductor industry’s demand for high-performance chips is soaring. Advanced manufacturing processes, new material applications, and precision production technologies have imposed increasingly stringent requirements on the cleanliness, airflow stability, and intelligent control of production environments. As a world-leading provider of fan and ventilation system solutions, ebm-papst has leveraged over 70 years of technical expertise to develop a range of customized fan products and system solutions tailored to the unique scenarios of semiconductor cleanrooms and clean plants. By virtue of its core technologies, ebm-papst empowers high-tech intelligent manufacturing, injecting strong impetus into the efficient and green development of the semiconductor industry.

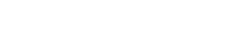

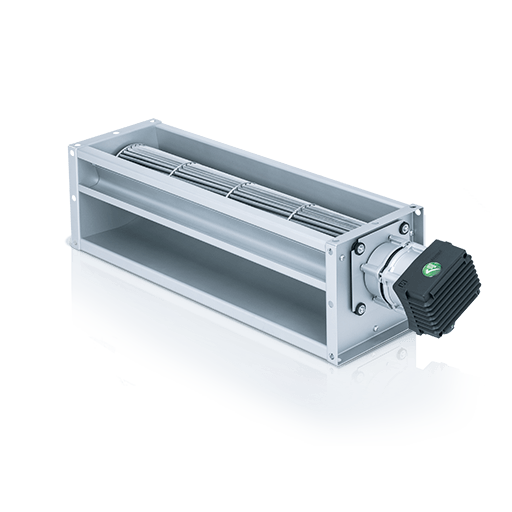

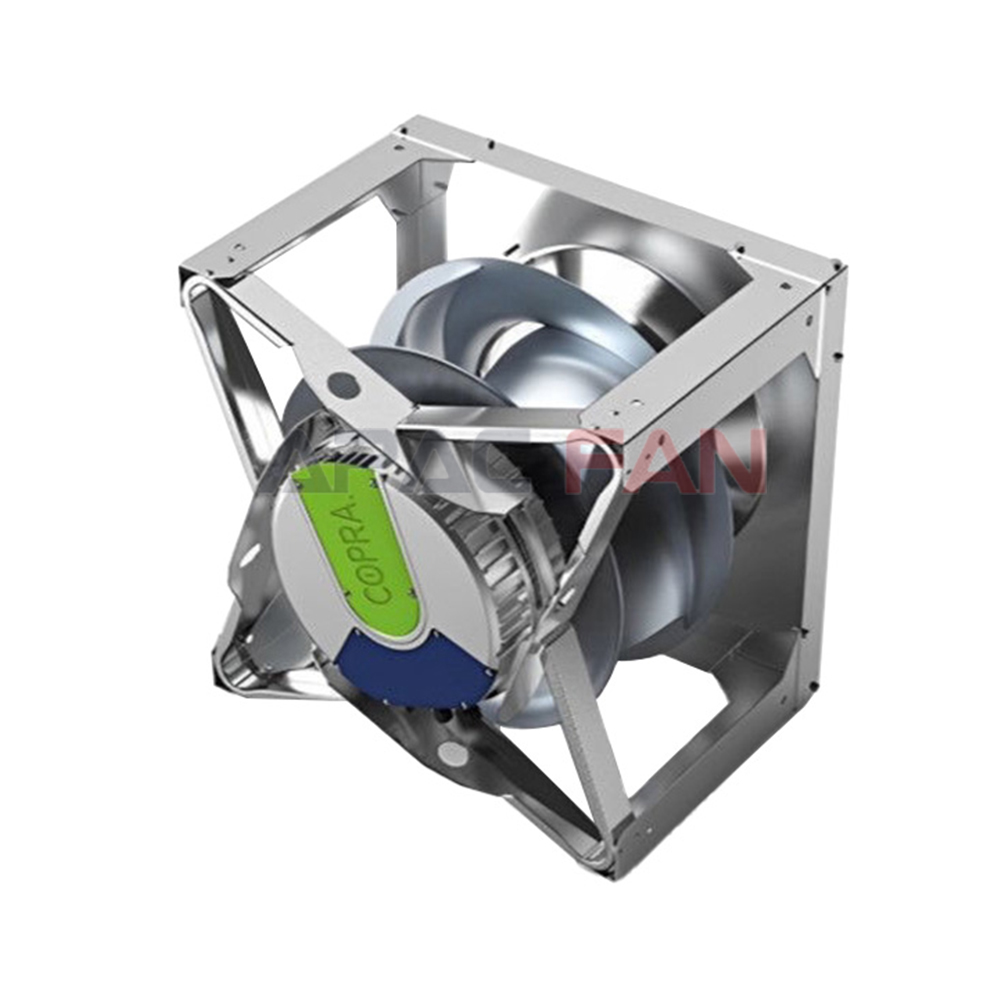

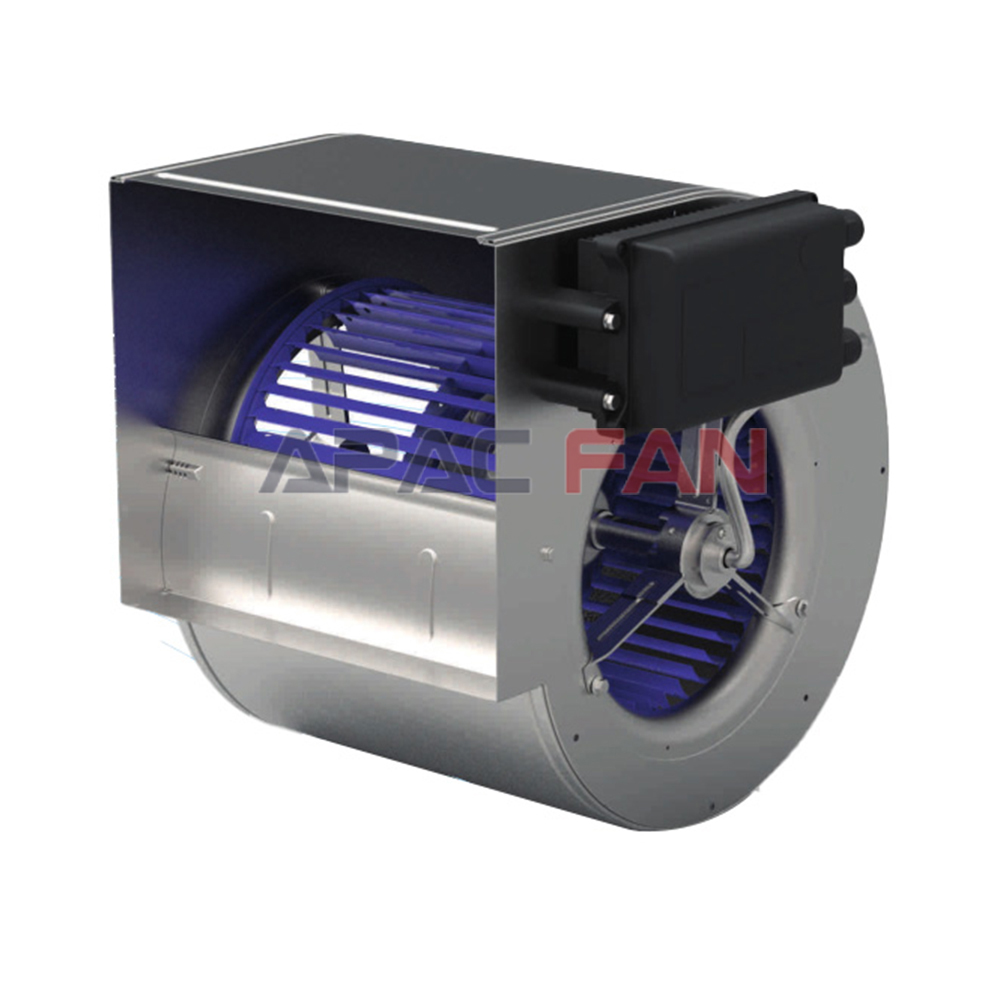

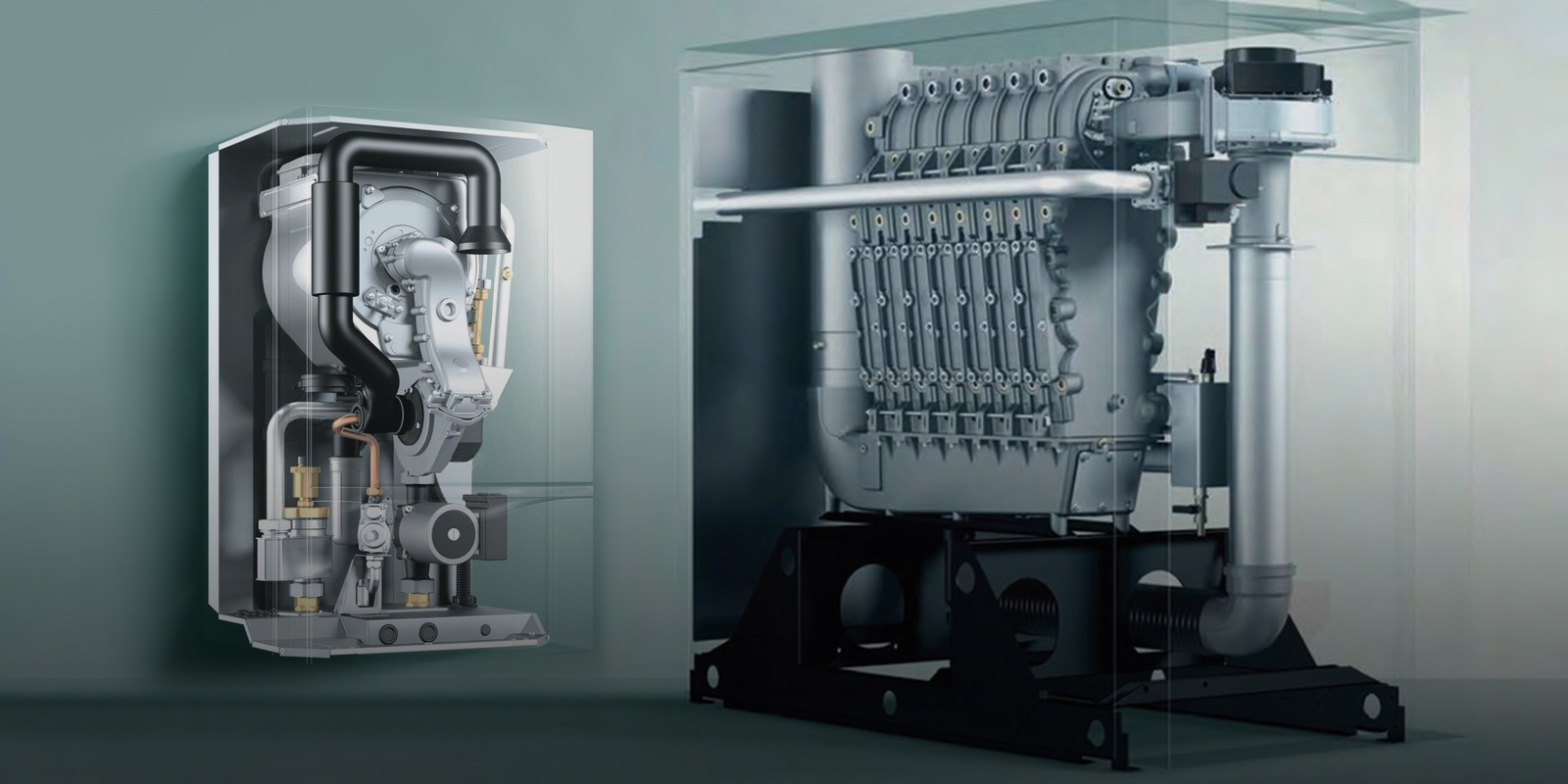

In FFUs (Fan Filter Units) and EFUs (Energy Recovery Fan Filter Units), the core equipment of semiconductor cleanrooms, fans serve as the key power components whose performance directly determines the stability of clean environments and production efficiency. Having deeply cultivated this field for years, ebm-papst’s fan products not only boast fundamental advantages including compact size, high operational efficiency, and low noise levels but also achieve breakthrough innovations in precision control and connectivity, perfectly meeting the high standards of semiconductor manufacturing. The new-generation RadiPac 3CR centrifugal fans are custom-designed for FFU applications, adopting an innovative full 3D blade profile design. The optimized curved blade structure ensures smoother airflow and more uniform air supply, effectively reducing kinetic energy loss during air transmission while significantly suppressing turbulent noise. Even under high-speed operation, the fans maintain ultra-low noise levels, creating a quiet and stable production environment for cleanrooms. In addition, this series of EC fans feature a flat structural design with small size and light weight, enabling easy integration with various compact FFUs. They achieve high-efficiency ventilation within limited installation spaces, greatly enhancing the flexibility and practicality of equipment integration.

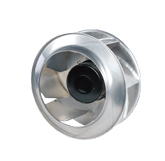

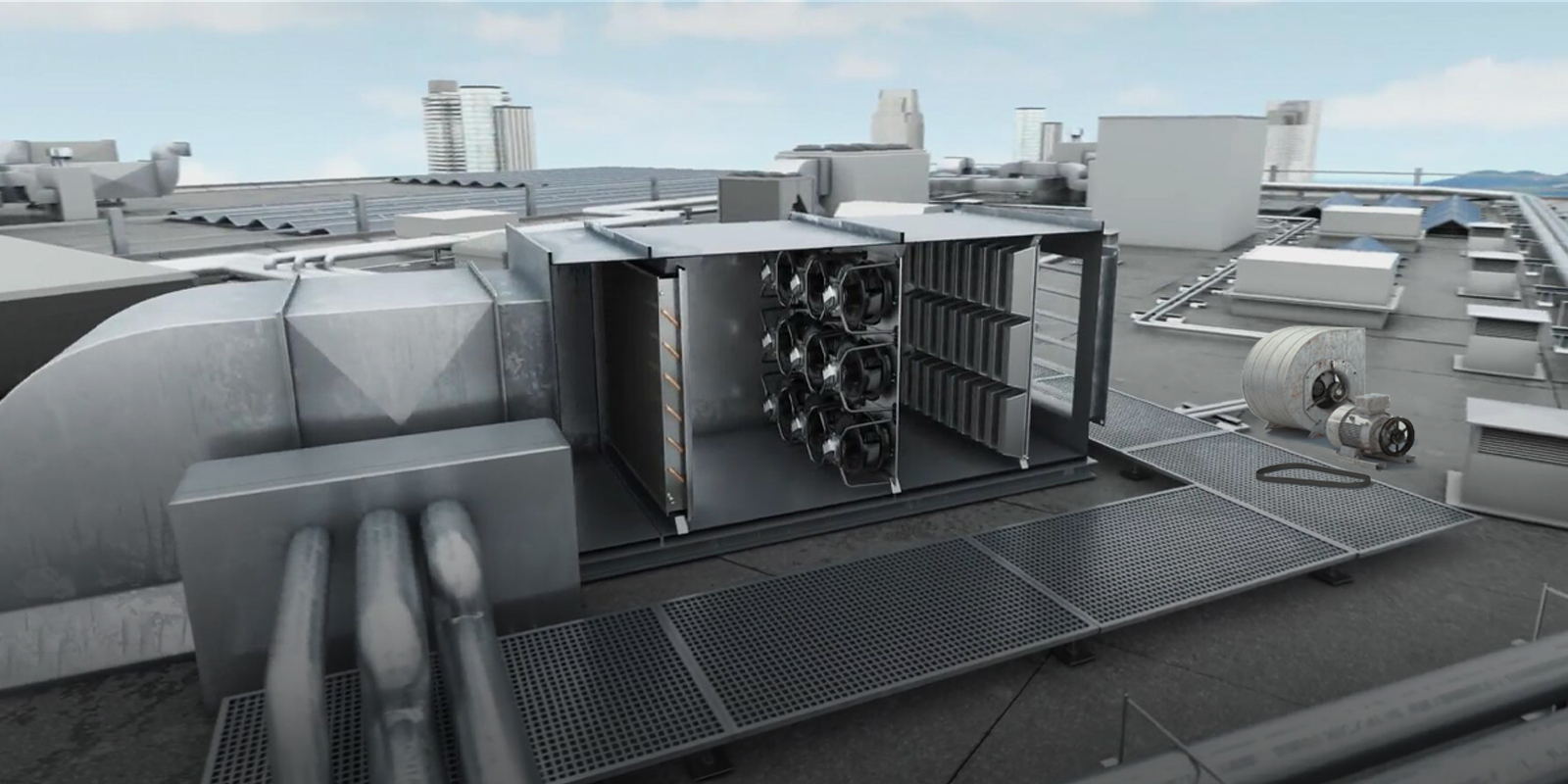

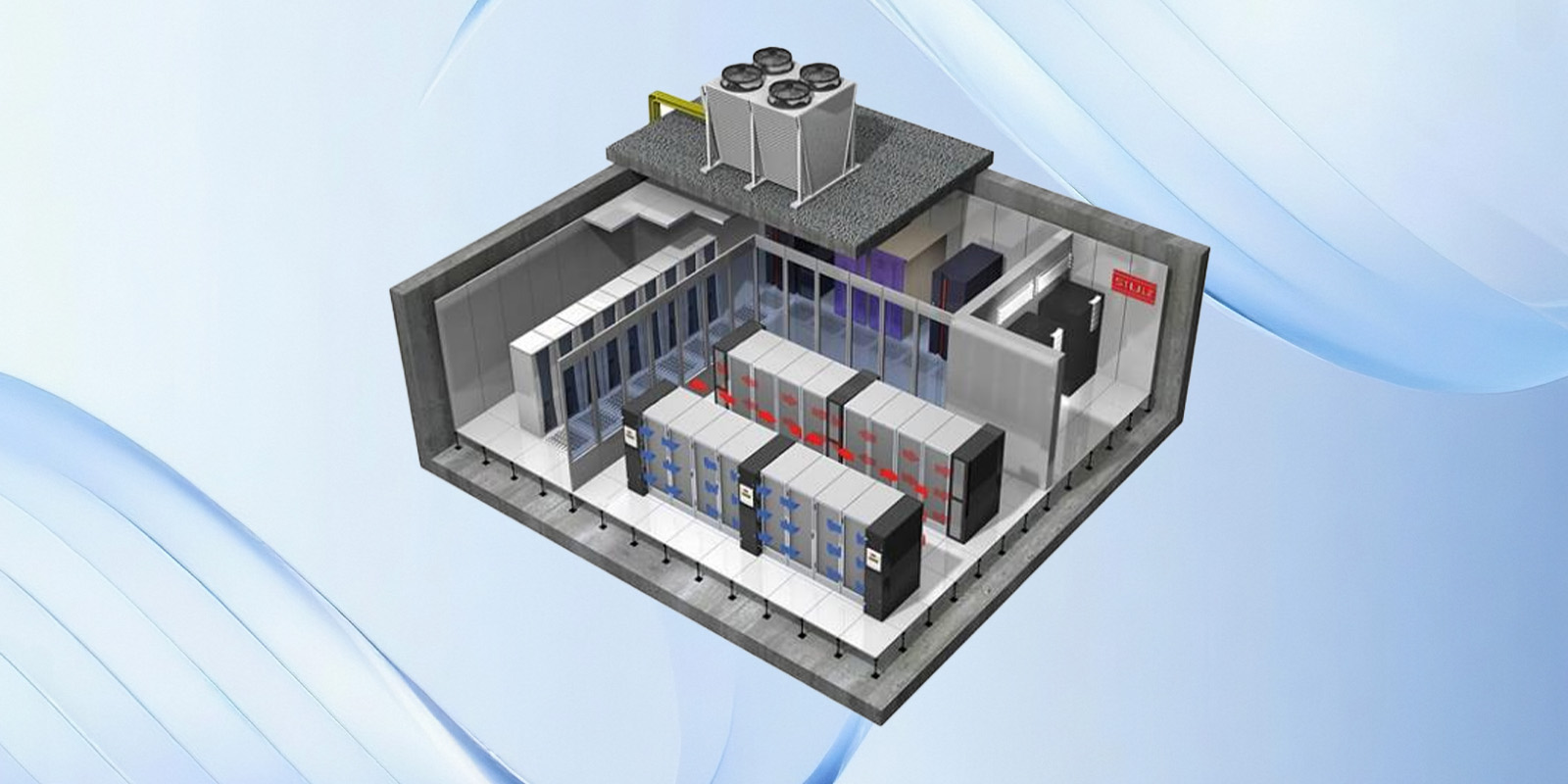

Beyond core fan products, ebm-papst provides full-scenario and targeted system solutions to meet the ventilation needs of cleanrooms and even entire clean plants. During semiconductor manufacturing, different processes vary significantly in their requirements for temperature, humidity, cleanliness, and airflow velocity. Through precise airflow simulation and system design, ebm-papst matches each key production link with an optimal ventilation solution. The ventilation system centered on EC fans delivers exceptional constant air volume control capability. Equipped with built-in high-precision sensors and intelligent control modules, it can real-time detect airflow changes and automatically adjust fan operation parameters, ensuring that the air volume in cleanrooms remains consistently within the set range regardless of external environmental fluctuations, thus providing a stable and reliable environmental guarantee for chip manufacturing.

Meanwhile, the fans support the MODBUS communication protocol, enabling seamless integration into factory intelligent management systems to realize remote monitoring, parameter adjustment, and fault pre-warning. Without the need to be physically present at the site, managers can real-time monitor fan operation status through the background system and flexibly adjust operating parameters based on production demands, achieving demand-driven high-efficiency operation and greatly improving the intelligence level and operational efficiency of plant management.

As the semiconductor industry pursues green and sustainable development, ebm-papst has deeply integrated energy-saving concepts into product and solution design, helping the industry build a green ecosystem. Its EC fans adopt high-efficiency brushless DC motors and optimized aerodynamic designs, with motor efficiency far exceeding that of traditional asynchronous motors. Energy consumption is reduced by more than 30% compared with similar products. Long-term operation can help semiconductor enterprises significantly cut power consumption, lower production costs, and reduce carbon emissions. In addition, the fans use long-life bearings and high-quality materials, offering excellent stability and durability with a mean time between failures far exceeding industry standards. This reduces the frequency of equipment replacement and maintenance, not only cutting operation and maintenance costs but also minimizing waste generation, which aligns with the concept of circular economy. Through the in-depth integration of technological innovation and green design, ebm-papst’s ventilation solutions not only meet the stringent requirements of semiconductor manufacturing but also provide a practical path for the sustainable development of the industry.

As an important partner in the innovative development of the semiconductor industry, ebm-papst has always taken technological innovation as its core driving force, continuously dedicating itself to the R&D and optimization of fan technologies and ventilation system solutions. From RadiPac 3CR centrifugal fans dedicated to FFUs to intelligent ventilation systems for entire plants, ebm-papst provides solid guarantees for every link of semiconductor manufacturing with its precise control, high energy efficiency, stable and reliable products and solutions. Looking ahead, ebm-papst will continue to focus on the technological needs of the semiconductor industry, break through technical bottlenecks, and launch more innovative products adapted to emerging manufacturing processes and smart factories. Working hand in hand with semiconductor enterprises worldwide, ebm-papst will jointly drive the industry towards a smarter, more efficient, and greener future, helping build a sustainable semiconductor industry ecosystem.

English

English Français

Français Deutsch

Deutsch Português

Português Español

Español русский

русский  한국어

한국어 العربية

العربية Italiano

Italiano Indonesia

Indonesia Schweiz

Schweiz Polski

Polski Nederlands

Nederlands ישראל - עברית

ישראל - עברית Perzisch

Perzisch ไทย

ไทย 日本語

日本語 ኢትዮ-አማርኛ

ኢትዮ-አማርኛ Việt Nam

Việt Nam Kiswahili

Kiswahili Srpski

Srpski Ελληνικά

Ελληνικά 繁體中文

繁體中文